High-Quality Centerless Bar Grinding Machines Revolutionizing Precision Manufacturing

In today's fast-paced manufacturing industry, precision and efficiency are paramount. One of the key players in achieving these goals is the high-quality centerless bar grinding machine. This specialized equipment has transformed the way manufacturers approach bar grinding, providing unparalleled accuracy and speed that enhance productivity across various applications.

Understanding Centerless Grinding

Centerless grinding is a machining process that involves the removal of material from a workpiece without the need for center holes, thereby allowing for continuous production. Unlike traditional cylindrical grinding machines that require the workpiece to be mounted on a spindle, centerless grinders hold the workpiece between two rotary wheels the grinding wheel and the regulating wheel. This configuration offers several advantages, including the ability to grind long, slender parts efficiently and the ability to achieve precise diameters and finishes.

Benefits of High-Quality Centerless Bar Grinding Machines

1. Precision and Consistency High-quality centerless grinding machines are designed to deliver exceptional precision. Advanced CNC technology allows for tight tolerances and repeatability, ensuring that every part meets the exact specifications. This is particularly important in industries where precision is critical, such as aerospace, automotive, and medical device manufacturing.

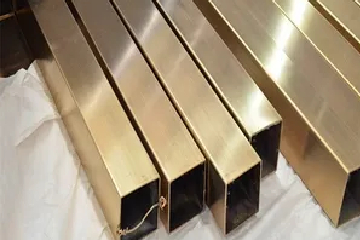

high quality centerless bar grinding machine

2. Increased Production Rates The configuration of centerless grinding machines allows for uninterrupted material feeding, significantly speeding up the production process. With the ability to process multiple parts continuously, manufacturers can increase their output without sacrificing quality. This enhanced efficiency translates to reduced lead times and lower costs, making it a vital tool in competitive markets.

3. Versatility High-quality centerless bar grinding machines are versatile and can handle a variety of materials, including steel, aluminum, brass, and plastics. They can accommodate different sizes and shapes of bars, making them suitable for a wide range of applications. This versatility allows manufacturers to use a single machine for multiple tasks, streamlining operations and minimizing equipment costs.

4. Low Maintenance Requirements Modern centerless grinding machines are engineered with durability in mind. They often come equipped with self-lubricating systems and robust construction that reduce wear and tear. This design translates into lower maintenance requirements and operational costs, allowing manufacturers to allocate resources more effectively.

5. Enhanced Surface Finish Achieving a superior surface finish is essential for many manufacturing processes. High-quality centerless bar grinding machines utilize advanced grinding wheels and techniques that result in exceptional surface quality. This is crucial for parts that will undergo additional processes like plating or coating, where surface integrity plays a key role in adhesion and performance.

Conclusion

In conclusion, high-quality centerless bar grinding machines have revolutionized the manufacturing landscape by offering precise, efficient, and versatile solutions for bar grinding needs. As industries continue to demand higher accuracy and faster production times, these machines stand out as indispensable tools that enhance productivity and reduce operational costs. Investing in advanced centerless grinding technology not only boosts manufacturing capabilities but also positions companies for future growth in an increasingly competitive market. With continued innovations in machine design and technology, the future of centerless grinding looks promising, paving the way for even greater advancements in precision manufacturing.