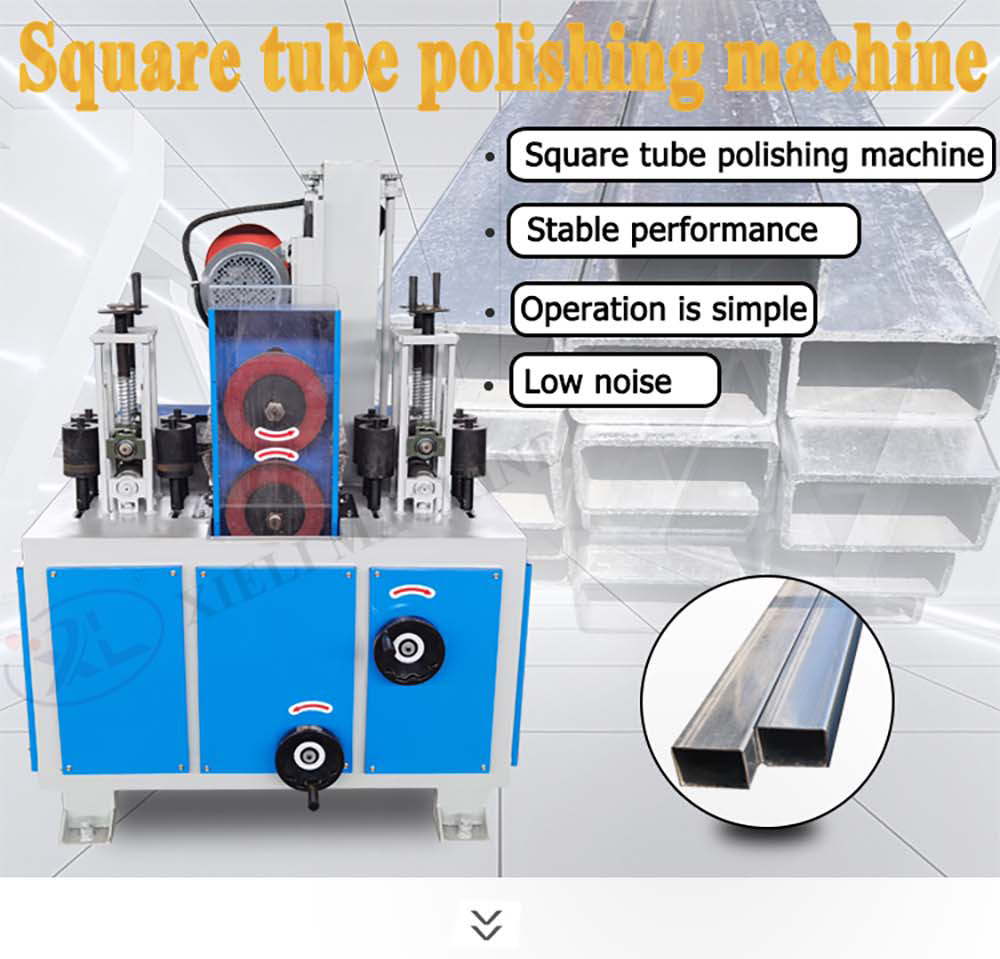

FG Series Square Tube Polishing Machine: A Revolution in Metal Surface Finishing

The FG series square tube polishing machine represents a significant advancement in metal surface finishing technology. Designed for industrial applications, this machine combines precision engineering with advanced automation to deliver high-quality polishing results for square tubes, square steel, and other profiled sections. Whether you're working with metallic or non-metallic materials, the FG series ensures efficiency, consistency, and superior finish quality. This article explores the machine's features, technical specifications, applications, and the company behind its innovation.

Key Features and Advantages

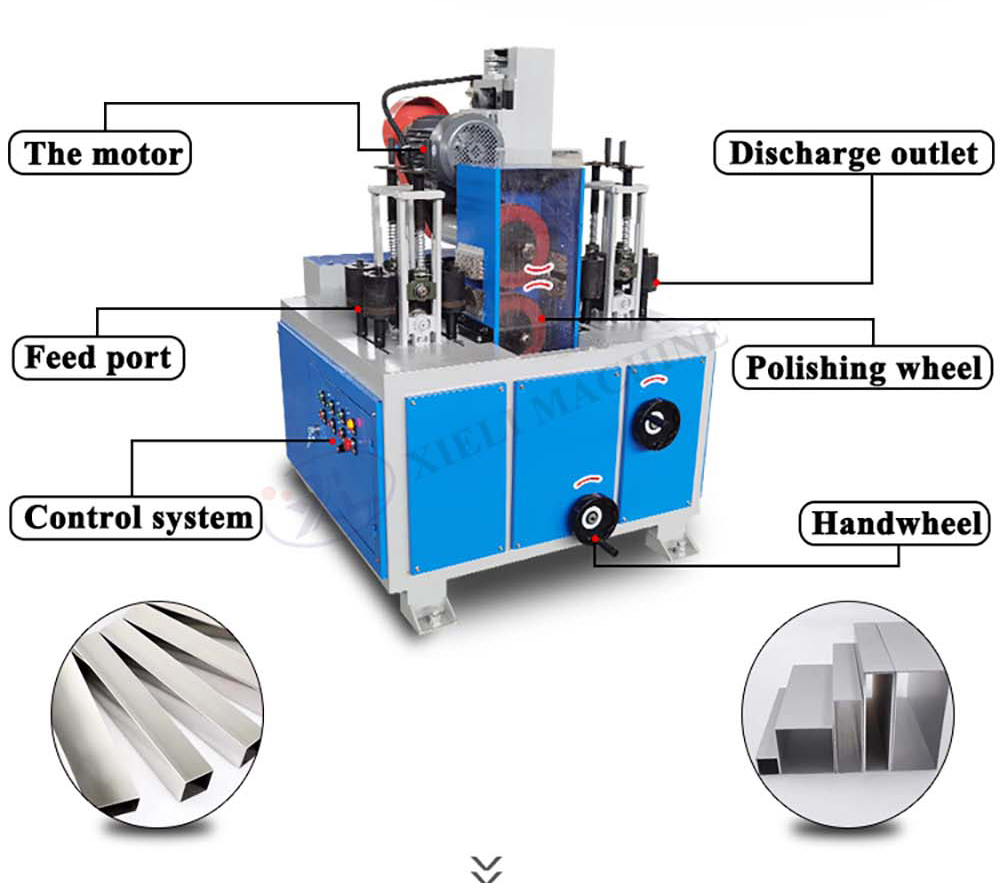

The FG series square tube polishing machine is engineered to address the challenges of traditional manual and mechanical polishing methods. Its design emphasizes efficiency, precision, and adaptability, making it a preferred choice for manufacturers in various industries. Below are the standout features of this advanced equipment:

- High Work Efficiency: The machine's electronic control system ensures accurate positioning and high-speed processing, significantly reducing labor costs and time compared to conventional methods. NIST standards for precision manufacturing align closely with the FG series' capabilities, ensuring compliance with industry benchmarks.

- Superior Polishing Quality: Advanced cutting parameters and high-precision grinding mechanisms produce smooth, even surfaces with a high-gloss finish. This meets the stringent requirements of industries such as aerospace, automotive, and medical device manufacturing.

- Multi-Functional Flexibility: The machine can handle square tubes of varying shapes, sizes, and materials. It supports a range of grinding tools, including emery cloth wheels, nylon wheels, and PVA wheels, allowing customization for specific applications.

- Customizable Design: Special polishing equipment can be tailored to meet unique user requirements, ensuring optimal performance for diverse production needs.

Technical Specifications

The FG series square tube polishing machine is available in multiple models, each designed to handle different tube dimensions and production volumes. Below is a detailed specification table for the FG-2, FG-4, FG-8, FG-16, and FG-24 models:

| Project | FG-2 | FG-4 | FG-8 | FG-16 | FG-24 | |

|---|---|---|---|---|---|---|

| Polished Square Tube Specifications (mm) | 120 | 10*10X120*120 | ||||

| 160 | 10*10X160*160 | |||||

| 200 | 50*50X200*200 | |||||

| 300 | 50*50X300*300 | |||||

| Polishing Grinding Heads Number (pcs.) | 2 | 4 | 8 | 16 | 24 | |

| Machined Workpiece Length (m) | 0.8-12 | |||||

| Steel Pipe Feed Speed (m/min) | 0-20 (Customizable) | |||||

| External Diameter of Matching Polishing Wheel (mm) | 250-300 | |||||

| Grinding Head Speed (r/min) | 2800 | |||||

| Grinding Head Spindle Diameter (mm) | 120 | 32 | ||||

| 160 | 32 | |||||

| 200 | 50 | |||||

| 300 | 50 | |||||

| Grinding Head Motor Power (KW) | 120 | 4 | ||||

| 160 | 5.5 | |||||

| 200 | 7.5 | |||||

| 300 | 11 | |||||

| Grinding Head Feed Mode | Manual / Digital Display Electric (Optional) | |||||

| Dedusting Method | Dry Fan Bag | |||||

Applications and Industry Use Cases

The FG series square tube polishing machine is versatile, making it suitable for a wide range of industrial applications. Some key use cases include:

- Automotive Manufacturing: Polishing of square tubes used in vehicle frames and structural components, ensuring durability and aesthetic quality.

- Aerospace Industry: High-precision polishing of non-metallic and metallic profiles for aircraft parts, meeting strict safety and performance standards.

- Construction Sector: Finishing of square steel and pipes for architectural applications, enhancing both functionality and visual appeal.

- Medical Device Production: Ensuring sterile, smooth surfaces for medical instruments and equipment, critical for patient safety.

The machine's ability to handle diverse materials and shapes makes it a valuable asset in industries where precision and consistency are paramount. For more information on similar technologies, explore NIST's research on advanced manufacturing processes.

Company Background: Xingtai Xieli Machinery Manufacturing Co., Ltd.

The FG series square tube polishing machine is developed by Xingtai Xieli Machinery Manufacturing Co., Ltd., a leading manufacturer of industrial machinery based in China. With a focus on innovation and quality, the company has established itself as a trusted supplier of precision equipment for metalworking and surface finishing. Their commitment to research and development ensures that their products meet global standards, including those outlined by NIST for metrology and manufacturing excellence.

Xingtai Xieli's product lineup includes a variety of grinding and polishing machines, such as the cincinnati centerless grinder machine and mikrosa centerless grinding machine, which are widely used in industrial settings. The company's dedication to customer satisfaction and continuous improvement has made it a preferred partner for manufacturers worldwide.

Conclusion

The FG series square tube polishing machine exemplifies the fusion of advanced technology and industrial expertise. Its high efficiency, precision, and adaptability make it an indispensable tool for modern manufacturing. Whether you're in the automotive, aerospace, or construction industry, this machine offers a reliable solution to enhance product quality and production efficiency.

For further details about the FG series or to explore other products from Xingtai Xieli Machinery Manufacturing Co., Ltd., visit their official website. With a commitment to innovation and adherence to global standards, the company continues to drive advancements in metalworking technology.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. https://www.nist.gov/