The Importance of SS Pipe Buffing Machines in Modern Manufacturing

In the world of manufacturing and metalworking, the finish on a product can often be just as important as its structural integrity. For industries that work with stainless steel (SS), such as food processing, pharmaceuticals, and automotive sectors, the surface quality of metal components plays a crucial role in both aesthetics and functionality. This is where SS pipe buffing machines come into play, providing essential services that enhance the quality of stainless steel pipes and fittings.

Understanding SS Pipe Buffing

Buffing is a polishing process that uses a soft material to remove imperfections from the surface of metal workpieces, resulting in a mirror-like finish. This is particularly important for stainless steel because it is widely used in environments where hygiene is paramount, such as in food production facilities and medical equipment manufacturing. An effective buffing process not only improves the appearance but also increases corrosion resistance by creating a smoother surface that minimizes the adherence of contaminants.

How SS Pipe Buffing Machines Work

SS pipe buffing machines are designed with durability and efficiency in mind. These machines typically use a series of buffing wheels, often made from cotton or other soft materials, which are mounted on a rotating spindle. The stainless steel pipes are fed through the machine, and as they pass by the spinning buffing wheels, the surface imperfections are gradually polished away.

Many modern buffing machines are equipped with advanced features such as variable speed controls, automated feeding mechanisms, and computer numerical control (CNC) technology. These innovations allow for consistency and precision in the buffing process, ensuring that each pipe achieves the desired finish without compromise. Additionally, these machines can be customized to handle different pipe sizes and shapes, making them versatile for various industrial applications.

Benefits of Using SS Pipe Buffing Machines

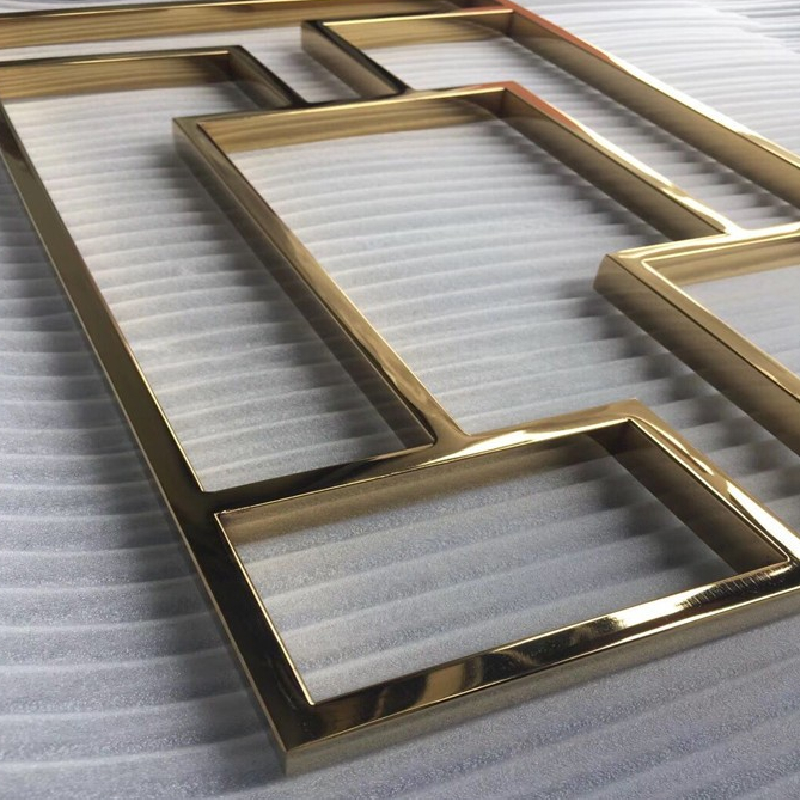

ss pipe buffing machine

1. Enhanced Aesthetic Appeal A polished surface not only looks good but also reflects professionalism and care in manufacturing processes. Buffed stainless steel pipes are often preferred in visible applications where appearance matters.

2. Increased Corrosion Resistance By removing surface imperfections, buffing helps prevent the accumulation of dirt, grime, and moisture, which can lead to corrosion over time. This is especially critical in environments that demand high sanitation standards.

3. Improved Performance Smoother surfaces reduce friction and wear in applications where metal components interact. This can lead to longer service life and less frequent replacements, thus saving costs for manufacturers.

4. Time Efficiency Automated SS pipe buffing machines can work quickly and consistently, allowing manufacturers to increase their output without sacrificing quality. This is particularly beneficial in high-volume settings where time is of the essence.

5. Safety Buffing machines often come with safety features that protect operators from injury, such as protective shields and emergency stop buttons. This makes them a safer option compared to manual buffing processes.

The Future of SS Pipe Buffing Technology

As technology continues to advance, the capabilities of SS pipe buffing machines are likely to improve as well. Innovations such as increased automation, artificial intelligence, and enhanced material science may lead to even more effective buffing techniques that reduce waste and improve energy efficiency. Furthermore, the demand for high-quality finishes in energy-efficient and sustainable products will likely drive the development of specialized buffing machines tailored to specific industries.

In conclusion, SS pipe buffing machines play a crucial role in the manufacturing process, contributing not only to the quality of the final product but also to the efficiency and safety of production. As industries continue to evolve and demand higher standards, the technology behind buffing machines will undoubtedly advance, paving the way for superior surface finishes that meet the ever-growing expectations of the market. For manufacturers working with stainless steel, investing in high-quality buffing machines is not just an option but a necessity to remain competitive in a crowded landscape.