The Rise of Tube Buffing Machine Manufacturers A Comprehensive Overview

In recent years, the manufacturing industry has witnessed significant advancements driven by technological innovation and the ever-increasing demand for high-quality products. Among these advancements, tube buffing machines have gained considerable attention. These machines play a critical role in the finishing process of various metal tubes, ensuring they not only have an aesthetic appeal but also improved durability and resistance to environmental factors. This article delves into the role of tube buffing machine manufacturers, the technology behind these machines, and the future trends in this sector.

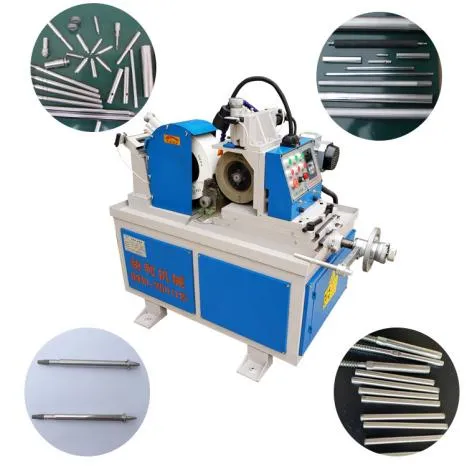

Understanding Tube Buffing Machines

Tube buffing machines are designed to smooth and polish metal tubes, removing imperfections and enhancing the surface quality. The buffing process involves the use of abrasive materials, typically cloth or felt wheels coated with polishing compounds. As the tube is fed into the machine, the rotating wheels come into contact with the surface of the metal, effectively buffing it to a high shine and reducing surface roughness.

These machines cater to a wide array of industries, including automotive, aerospace, furniture manufacturing, and plumbing. Manufacturers of stainless steel, aluminum, and other metals find tube buffing machines indispensable for achieving the desired finish on their products.

The Role of Manufacturers

Tube buffing machine manufacturers are pivotal in the production and supply chain of polished metal products. They are responsible for designing, developing, and producing machines that meet the evolving needs of various industries. The quality, durability, and efficiency of the machines they manufacture not only determine the final product’s quality but also impact the productivity of the end-users.

A reputable manufacturer invests in research and development to design machines that incorporate the latest technologies. This includes automation, where advanced sensors and robotics are employed to streamline the buffing process, enhance precision, and reduce labor costs. Furthermore, sustainable practices are becoming increasingly important, prompting manufacturers to design energy-efficient machines that minimize waste and environmental impact.

Key Features of Tube Buffing Machines

Manufacturers focus on several features when designing tube buffing machines

tube buffing machine manufacturers

2. Automation Incorporating automated controls that require minimal human intervention can significantly enhance efficiency and reduce the risk of error.

3. Customization Different applications may require specific buffing techniques and finishes. Leading manufacturers offer customization options to meet the unique demands of their customers.

4. User-Friendly Interfaces With an increase in the use of technology in manufacturing, user-friendly control panels facilitate easier operation of the machines, even for less experienced staff.

The Future of Tube Buffing Machine Manufacturing

The future of tube buffing machine manufacturers appears promising, with several trends shaping the industry. The integration of Industry 4.0 technologies stands out, with manufacturers leveraging the Internet of Things (IoT), artificial intelligence, and machine learning to create smart machines that can predict maintenance needs, optimize performance, and collect data for improved processes.

Additionally, as environmental concerns continue to rise, manufacturers are likely to focus on sustainable practices. This means creating machines that utilize eco-friendly materials and energy-efficient operations.

Moreover, the globalization of supply chains presents both challenges and opportunities for manufacturers. As companies expand their reach to international markets, the demand for high-quality tubes and finishing processes will drive the growth of tube buffing machine manufacturers worldwide.

Conclusion

In conclusion, tube buffing machine manufacturers play a vital role in the manufacturing sector by providing essential technology that enhances product quality and production efficiency. As the industry grows and evolves, so too will the machines that define it. Embracing technological advancements and sustainable practices will be crucial for manufacturers looking to thrive in an increasingly competitive landscape. The future of tube buffing machines is bright, promising innovation and enhanced capabilities that will continue to meet the demands of diverse industries.