Aluminium tube polishing machine manufacturers are experiencing unprecedented demand as industries ranging from aerospace to automotive strive for excellence in product finishing. Located at the intersection of precision engineering and industrial efficiency, these manufacturers are tasked with delivering machines that not only meet diverse polishing needs but also adhere to strict industry standards. Understanding what sets a top-tier aluminium tube polishing machine manufacturer apart can significantly impact the purchasing decision for businesses seeking reliable equipment.

Precision is the cornerstone of effective aluminium tube polishing. High-quality machines offer unparalleled consistency, utilizing advanced technology to ensure that every tube is polished to exact specifications. The best manufacturers employ cutting-edge automation in their equipment, allowing businesses to minimize human error and maximize the uniformity of their outputs. Automated systems are designed to adapt to the intricate geometries of aluminium tubes, delivering a flawless finish that enhances the functional and aesthetic properties of the end product.

In terms of expertise, leading manufacturers distinguish themselves through innovation and adaptability. The production capabilities of these companies are continually evolving, integrating new technological developments to cater to the increased complexity of modern demands. For example, state-of-the-art models from industry leaders feature intelligent feedback systems that dynamically adjust the polishing process in real-time, responding to variables such as tube size and surface condition to ensure optimal results.

The authority of a manufacturer in this field is often reflected in their portfolio of partnerships and certifications. Collaborating with key industry players and holding certifications from recognized bodies signals a commitment to quality and compliance. Clients can trust that these manufacturers adhere to best practices not only in the performance of their machines but also in their production processes, from materials sourcing to assembly.

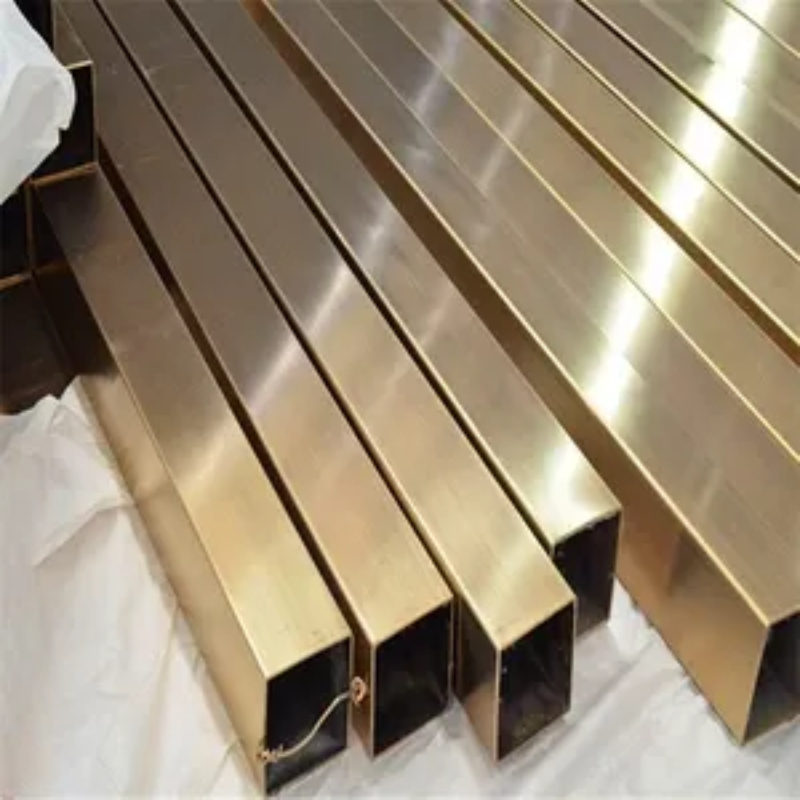

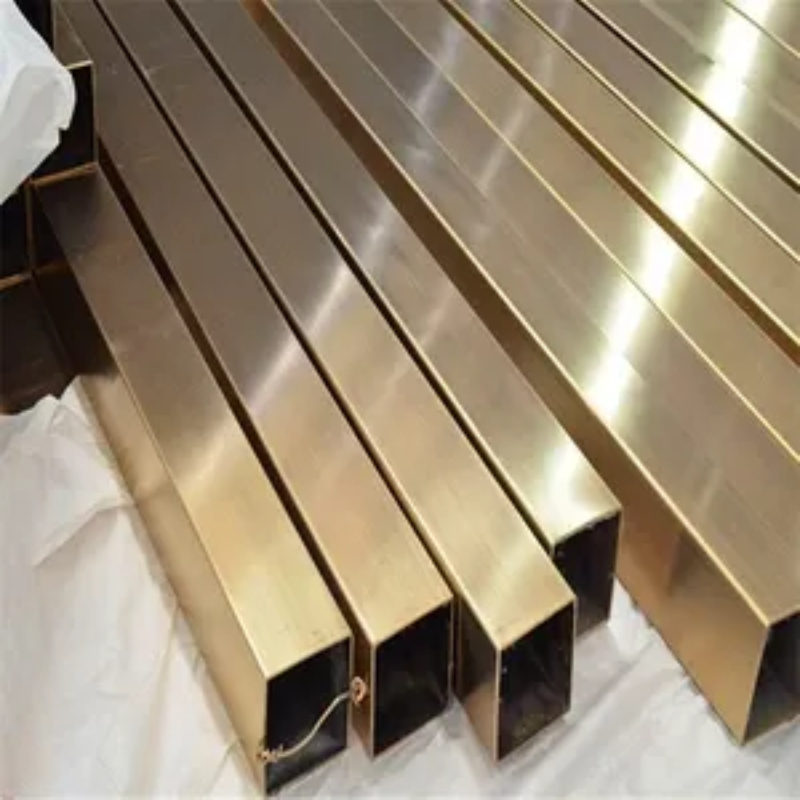

aluminium tube polishing machine manufacturer

Trustworthiness is further established through customer service and support. An excellent manufacturer does not disappear after the sale. Instead, they provide ongoing training, maintenance packages, and technical support to ensure that their machines continue to perform at peak efficiency. Clients benefit from a dedicated support team capable of responding promptly to any operational concerns, reducing downtime and maintaining productivity.

Deepening the trust equation is the manufacturer’s transparency regarding product performance and capabilities. Prospective buyers benefit from clear, data-driven insights into the machine's efficiency, cost-effectiveness, and return on investment. This data empowers businesses to align their purchasing decisions with strategic financial goals, making the acquisition of a polishing machine a confident step forward.

Fostering long-term relationships with clients also requires the ability to customize solutions. The top aluminium tube polishing machine manufacturers understand that different industries have unique needs. Customization might involve adjusting machine settings, upgrading specific components, or designing entirely bespoke systems. This flexibility ensures that regardless of the complexity or scale of the task, the client receives a product that fits seamlessly into their existing operations.

In conclusion, when selecting an aluminium tube polishing machine manufacturer, potential clients should prioritize factors such as precision, expertise, authority, and trustworthiness. These indicators are not just abstract values but tangible qualities that affect the performance, reliability, and overall satisfaction derived from the machine. By making informed decisions, businesses can enhance their operational efficiency, ensuring that their aluminium tubes meet the highest standards of polish and performance in their respective industries.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.