Exploring Tube Internal Polishing Machine Factories for Optimal Tube Finishing Solutions

In the realm of manufacturing, particularly in industries involving metal tubing, the importance of surface finish cannot be overstated. The internal surfaces of tubes must be smooth to enhance performance, prevent corrosion, and allow for better flow of substances within. This necessity has led to the proliferation of tube internal polishing machine factories around the globe, dedicated to producing machines that deliver precision and efficiency.

What is Tube Internal Polishing?

Tube internal polishing is a process that improves the internal finish of tubes. It typically involves the use of specialized machinery that employs various techniques, such as abrasive polishing, electro-polishing, or chemical methods, to achieve the desired surface quality. This process not only enhances the aesthetic appeal of the tubes but also plays a crucial role in how they function, especially in applications involving fluid dynamics or where hygiene is critical, such as in the food and pharmaceutical industries.

The Role of Tube Internal Polishing Machine Factories

These factories are essential in supplying the machinery required for tube polishing, which can vary significantly based on the specific application and material of the tube. Manufacturers of these machines must focus on several key factors

1. Technology and Innovation Factories are increasingly integrating advanced technologies into their machines. Automation, for example, plays a vital role in ensuring consistency and precision in the polishing process. Smart machines that can monitor and adjust parameters in real-time offer significant advantages in efficiency and quality control.

2. Customization Each application may have unique requirements, and hence, many factories offer customized solutions to meet specific industry standards. Customization can include varying the size of the machine, the type of polishing technique used, and the degree of automation desired.

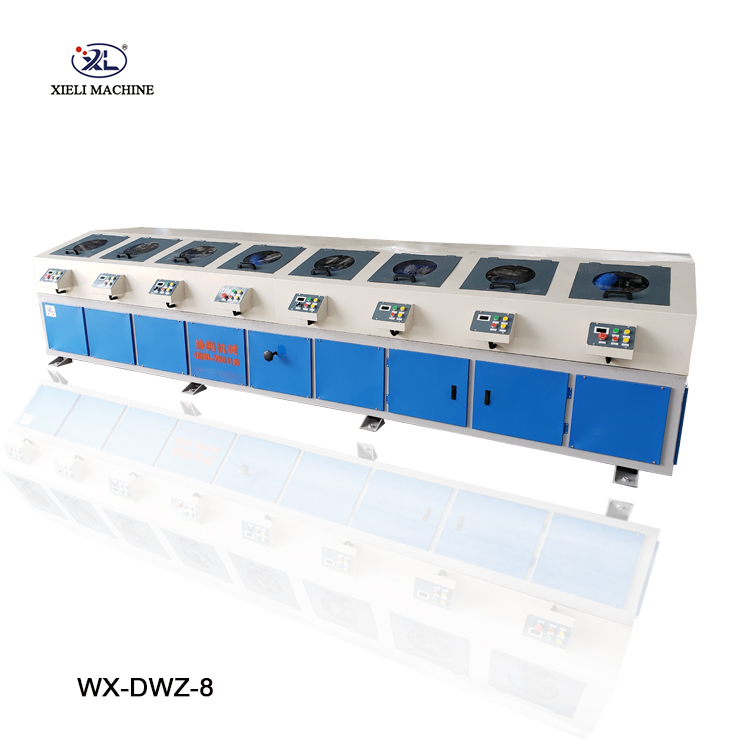

tube internal polishing machine factories

3. Material Compatibility The machines must be compatible with a range of materials, including stainless steel, aluminum, and other alloys. Factories aim to provide versatile machines that can handle various materials while maintaining high polishing performance.

4. Environmental Considerations With growing concerns over environmental impact, many manufacturers are developing eco-friendly polishing solutions. This includes machines that utilize less water, produce fewer emissions, and employ biodegradable polishing compounds.

5. Quality Assurance The factories must adhere to stringent quality standards to deliver reliable machines. This ensures that the internal polishing machines function effectively and provide consistent results. Quality assurance processes include rigorous testing and certification to meet both national and international standards.

Market Dynamics and Global Reach

The demand for tube internal polishing machines is rising, driven by various sectors, including automotive, aerospace, and medical device manufacturing. This growth has led to an increase in the number of tube internal polishing machine factories worldwide, particularly in regions known for robust manufacturing capabilities such as China, Germany, and the United States.

Conclusion

In summary, tube internal polishing machine factories play a critical role in modern manufacturing, providing essential equipment that ensures tubes meet required specifications for a variety of applications. As industries continue to evolve, the demand for improved surface finishes will drive innovation in polishing technologies. With advancements in automation, customization, and environmental sustainability, these factories are poised to meet the growing needs of manufacturers around the world, ultimately enhancing product quality and performance across numerous sectors. As industries push for greater efficiency and excellence, the role of tube internal polishing machinery is set to be more significant than ever before.