The Advantages of Stainless Steel Mirror Polishing Machines

Stainless steel is renowned for its durability, resistance to corrosion, and aesthetic appeal. As industries increasingly rely on stainless steel for various applications, the demand for stainless steel mirror polishing machines has surged. These machines are essential for producing high-quality, mirror-like finishes on stainless steel surfaces, and they come with a plethora of advantages.

Understanding Mirror Polishing

Mirror polishing is a finishing process that involves refining the surface of stainless steel to achieve a highly reflective and smooth surface. This process not only enhances the visual appeal of the metal but also contributes to its functionality. A polished surface is less likely to harbor dirt, grime, and bacteria, making it ideal for industries like food processing, healthcare, and architecture.

Benefits of Using Stainless Steel Mirror Polishing Machines

1. Enhanced Aesthetic Quality One of the most apparent advantages of mirror polishing is the enhanced aesthetic quality of the stainless steel. A polished surface reflects light beautifully, making products look more appealing. This quality is particularly important in industries focusing on consumer products, such as kitchenware and architectural elements, where appearance plays a significant role in consumer choice.

2. Increased Durability The mirror polishing process creates a smooth surface that is less prone to scratches and tarnishing. As a result, products treated with mirror polishing often exhibit greater longevity. This durability is critical in settings where stainless steel components are subjected to wear and tear.

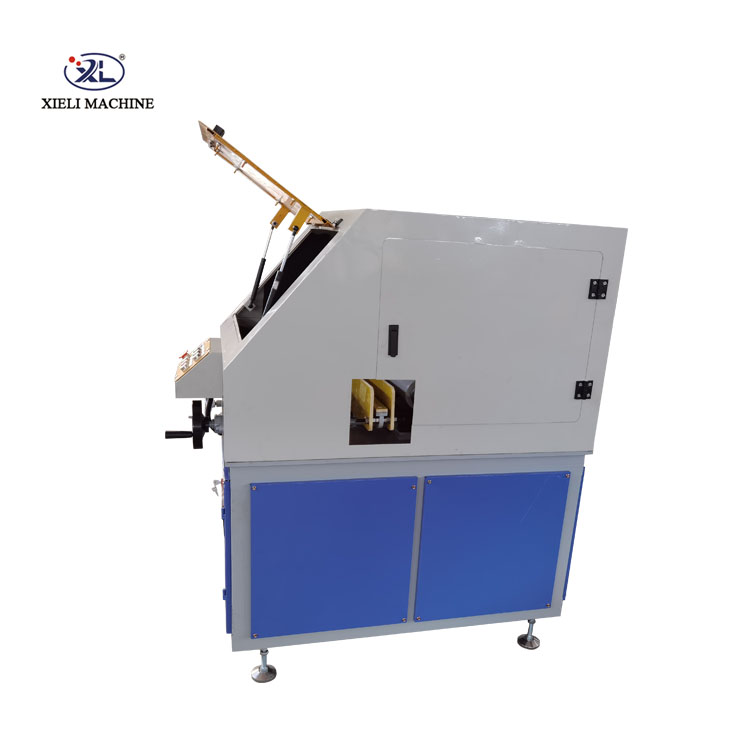

stainless steel mirror polishing machine

3. Corrosion Resistance The polishing process removes any impurities and contaminants from the surface of the stainless steel. This not only makes the material more visually appealing but also enhances its resistance to corrosion. A polished surface minimizes the risk of rust and degradation, which is particularly beneficial in harsh environments.

4. Hygienic Properties In industries such as food and beverage, pharmaceuticals, and healthcare, hygiene is paramount. The smooth, non-porous surface created by mirror polishing prevents the accumulation of bacteria and other harmful substances. This characteristic makes stainless steel mirror polishing machines indispensable for maintaining high hygiene standards.

5. Versatility Stainless steel mirror polishing machines are versatile and can be used on various stainless steel grades and forms, including sheets, pipes, and components. This adaptability allows manufacturers to cater to a wide range of applications, from decorative finishes in architecture to precise finishes in medical equipment.

6. Cost-Effectiveness While the initial investment in a stainless steel mirror polishing machine may be significant, the long-term savings can be substantial. By improving the quality and lifespan of products, reducing the need for frequent replacements, and minimizing maintenance costs, these machines contribute to a company’s bottom line.

Conclusion

In conclusion, stainless steel mirror polishing machines play a crucial role in modern manufacturing processes. They not only enhance the aesthetic appeal of products but also improve durability, corrosion resistance, and hygiene standards. As industries continue to embrace stainless steel for its numerous advantages, the importance of these machines will only grow. By investing in advanced polishing technology, manufacturers can ensure that they meet the demands of the market while delivering high-quality, visually appealing products that stand the test of time.