The Rise of China’s Small Centerless Grinders Precision Engineering for Modern Needs

In recent years, the manufacturing industry has seen a surge in the demand for precision equipment, particularly in the realm of grinding technologies. Among these, small centerless grinders from China have carved a niche for themselves, becoming integral to sectors such as automotive, aerospace, and general engineering. This article explores the features, advantages, and applications of small centerless grinders, highlighting their importance in today’s fast-paced industrial landscape.

What is a Centerless Grinder?

A centerless grinder is a machine that grinds cylindrical workpieces without the need for a center hole. The workpiece is held in place by two wheels the grinding wheel, which rotates at a high speed, and the regulating wheel, which controls the speed of the workpiece as it passes through the grinder. This contraption allows for continuous and efficient grinding operations, producing highly accurate and smooth surfaces on various materials.

The Emergence of Small Centerless Grinders in China

China has rapidly become a hub for manufacturing, with various sectors pushing for higher efficiency and precision. Small centerless grinders have emerged as a viable solution, thanks to advancements in technology and manufacturing capabilities. These compact machines are designed to cater to small to medium-sized workpieces, providing manufacturers with an excellent tool for achieving tight tolerances and perfect finishes in a limited space.

Advantages of Small Centerless Grinders

1. Space Efficiency One of the most significant benefits of small centerless grinders is their compact design. They can easily fit into smaller workshops or production lines, making them a favorable option for businesses with limited floor space.

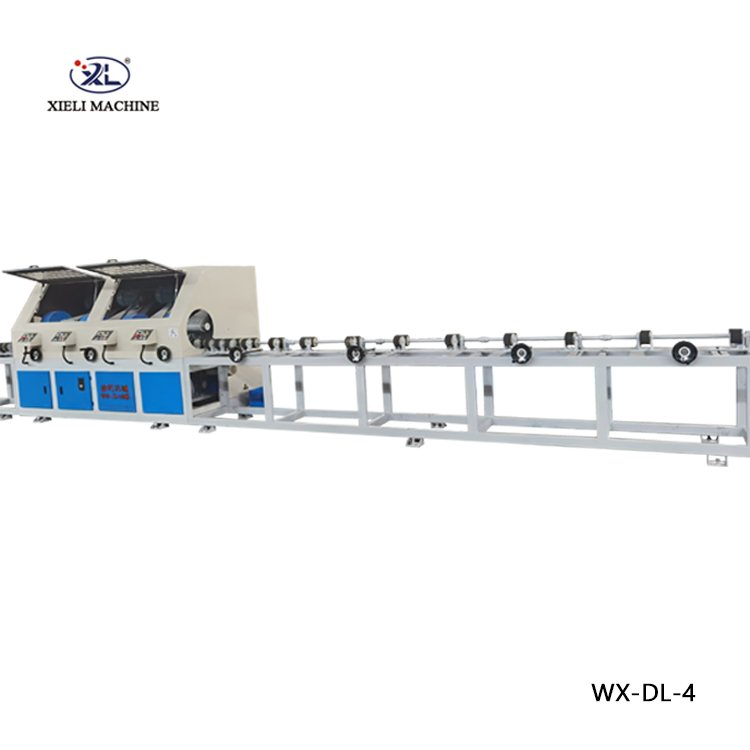

china small centerless grinder

2. High Precision and Quality These machines are engineered to deliver exceptional accuracy. The low-friction design and controlled process allow for high-quality finishes on various materials, including metals and plastics.

3. Cost-Effectiveness With China being a major manufacturer of machine tools, small centerless grinders come at competitive prices. This affordability allows smaller companies to invest in high-quality equipment without straining their budgets.

4. Reduced Setup Time Many small centerless grinders are designed for quick setup and easier operation. Operators can switch between different tasks with minimal downtime, thereby increasing overall productivity.

5. Versatile Applications The versatility of small centerless grinders makes them suitable for a wide range of applications. They are used for grinding parts such as rods, tubes, and other cylindrical components in industries like automotive, aerospace, and electronics.

The Future of Small Centerless Grinders in China

As the demand for precision engineering continues to grow, the market for small centerless grinders shows promising potential. Chinese manufacturers are investing in research and development to improve machine capabilities, focusing on automation and digital technologies. This trend toward smart manufacturing is likely to position China as a leader in the global machinery market.

In conclusion, small centerless grinders manufactured in China offer a unique blend of precision, efficiency, and affordability. As industries across the globe strive for better performance and tighter tolerances, these machines will play an essential role in meeting the evolving needs of modern manufacturing. Their emergence not only signifies technological advancement in grinding capabilities but also reflects China's increasing influence in the global industrial landscape. The future is bright for small centerless grinders, both domestically and internationally, as they help propel the manufacturing industry into a new era of productivity and innovation.