The Rise of Multi-Head Automatic Polishing Machine Factories

In the modern manufacturing landscape, efficiency and precision are paramount. The advent of multi-head automatic polishing machines has revolutionized the surface finishing industry, offering manufacturers a way to enhance productivity while maintaining high-quality standards. These machines are designed to cater to a variety of materials, including metals, plastics, and ceramics, making them indispensable tools in various sectors such as automotive, aerospace, and electronics.

Multi-head automatic polishing machines leverage advanced technology to perform polishing tasks with remarkable speed and precision. By incorporating multiple polishing heads, these machines can simultaneously refine the surfaces of multiple products or larger components, significantly reducing cycle times and increasing output. This capability is especially beneficial in high-volume production environments where time is of the essence. Manufacturers can meet tight deadlines without compromising on quality, ultimately improving their competitiveness in the market.

One of the key advantages of multi-head automatic polishing machines is their ability to provide consistent results. Manual polishing can vary significantly in quality due to human error, but automated systems ensure that each piece is polished uniformly. This consistency is essential in industries where surface integrity is critical, such as in aerospace components, where even slight irregularities can lead to catastrophic failures. By minimizing variability, these machines enhance the reliability of end products, fostering trust among clients and stakeholders.

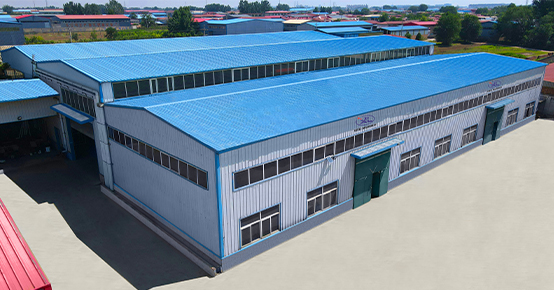

multi-head automatic polishing machine factories

Another notable feature of these machines is their adaptability. Many multi-head automatic polishing machines come with programmable settings, allowing manufacturers to tailor the polishing process based on specific requirements. This flexibility means that a single machine can process different materials and shapes, reducing the need for multiple machines and streamlining production lines. As industries continue to evolve, the ability to quickly adapt to new products and processes will be crucial for manufacturers aiming to stay ahead of the competition.

Moreover, the shift towards sustainability in manufacturing practices has driven the development of eco-friendly polishing systems. Many modern multi-head automatic polishing machines are designed to minimize waste and energy consumption. Features such as closed-loop water recycling systems and energy-efficient motors not only lower operational costs but also help manufacturers meet increasingly stringent environmental regulations.

In conclusion, multi-head automatic polishing machine factories are becoming essential players in the manufacturing sector. By providing faster, more consistent, and adaptable polishing solutions, they empower industries to enhance their productivity and quality standards. As technology continues to advance, these machines will likely become even more sophisticated, paving the way for innovations that further streamline production processes and contribute to sustainable manufacturing practices. As a result, embracing these technologies will be vital for companies looking to thrive in today’s competitive market.