The Importance of Wood Buffer Polishers in Woodworking

Woodworking is an art form that combines skill, creativity, and precision. Among the various tools available for woodworkers, the wood buffer polisher stands out as an essential instrument for achieving a smooth, refined finish. This article explores the significance of wood buffer polishers, their functions, and how they enhance the woodworking process.

Understanding Wood Buffer Polishers

A wood buffer polisher is a power tool designed specifically for polishing and finishing wooden surfaces. It typically comprises a rotating pad or wheel onto which polishing compounds are applied. When the buffer is activated, the wheel spins at high speeds, effectively polishing the wood surface and removing any imperfections, scratches, or dull spots. The end result is a gleaming finish that accentuates the natural beauty of the wood grain.

Functions of Wood Buffer Polishers

1. Smoothing Surfaces One of the primary functions of a wood buffer polisher is to smooth surfaces. After sanding, wood can often have lingering scratches or imperfections. A buffer polisher effectively removes these flaws, creating a glass-like finish that enhances the overall appearance of the piece.

2. Enhancing Grain The beauty of wood lies in its grain patterns and colors. A wood buffer polisher helps highlight these unique characteristics by applying even pressure and polish. This not only improves the aesthetic quality of the wood but also deepens its natural color, bringing out the richness of its appearance.

3. Applying Finishes Many wood buffer polishers are designed to apply finishes and waxes uniformly. Whether it's a penetrating oil, lacquer, or a natural beeswax finish, the buffer allows for an even coat that dries smoothly and lasts longer than manual applications. This ensures that the finished piece not only looks great but is also protected from environmental damage.

4. Time Efficiency Manual polishing can be labor-intensive and time-consuming. Wood buffer polishers significantly reduce the time needed to achieve a superb finish. By automating the polishing process, woodworkers can focus on other aspects of their projects, leading to more efficient workflows and higher productivity.

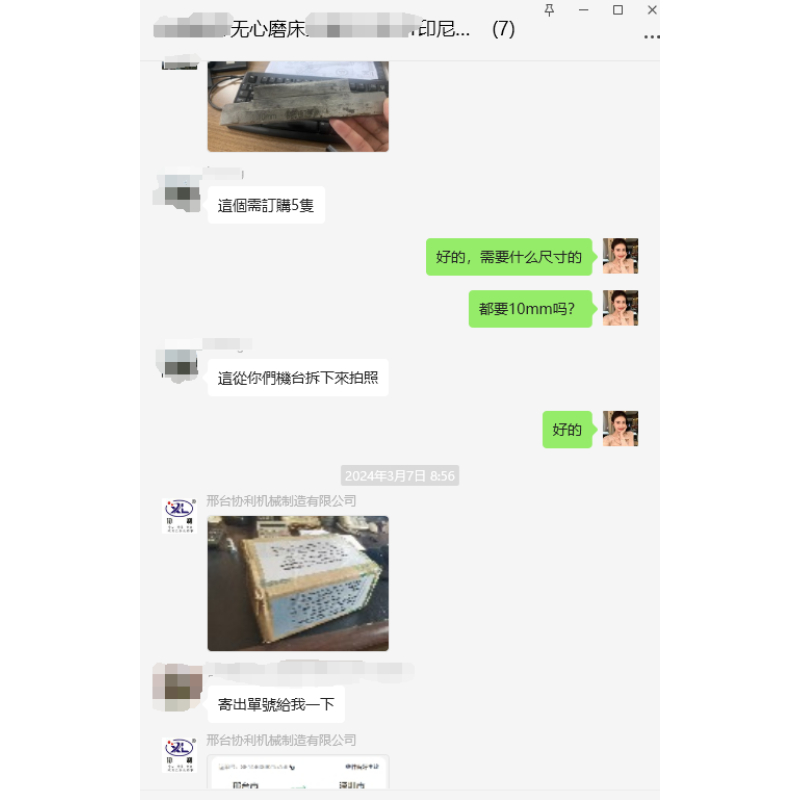

wood buffer polisher

Choosing the Right Wood Buffer Polisher

When selecting a wood buffer polisher, several factors should be considered

- Type Buffers come in various types, such as rotary, orbital, and dual-action. Each has its own advantages depending on the desired finish. Rotary buffers are powerful and effective for large surfaces, while orbital buffers provide a gentler touch for more delicate work.

- Speed Settings Different wood types require different speeds for optimal results. A polisher with adjustable speed settings allows woodworkers to customize the polishing process according to the specific needs of their projects.

- Pad Materials The choice of pad material is crucial for achieving the desired finish. Foam pads are great for applying wax or polish, while wool pads are more suited for heavy-duty buffing.

- Ergonomics Since polishing can be tedious, selecting a polisher that is comfortable to hold and maneuver can help reduce fatigue, especially during long working sessions.

Conclusion

In the realm of woodworking, achieving a high-quality finish is paramount. Wood buffer polishers play a vital role in this process, transforming raw wooden surfaces into stunning masterpieces. By understanding the functions and benefits of these tools, woodworkers can elevate their craft and create pieces that truly shine. Whether you are a novice or an experienced professional, incorporating a wood buffer polisher into your toolkit can streamline your finishing process and enhance the beauty of your wooden works.