The Importance of Wholesale Surface Grinders and Centerless Grinding in Manufacturing

In the world of manufacturing, precision and efficiency are paramount. Among the various tools and processes used to achieve high levels of accuracy in machining, surface grinders and centerless grinding machines play crucial roles. These technologies not only enhance product quality but also optimize production workflows.

Wholesale Surface Grinders

Wholesale surface grinders are critical in preparing and finishing parts to achieve a smooth and flat surface. These machines are available in various sizes and types, catering to both small workshops and large-scale manufacturing plants. The ability to source surface grinders wholesale allows manufacturers to equip their facilities with high-quality machinery while minimizing costs.

Surface grinders operate by moving a workpiece underneath a grinding wheel, which removes material to achieve the desired flatness and surface finish. This process is essential in industries where precision is crucial, such as aerospace, automotive, and electronics. The capability to achieve tolerances as tight as a few microns underscores the significance of these machines in maintaining high industry standards.

Centerless Grinding

Centerless grinding, on the other hand, is a process used primarily for cylindrical workpieces. In this method, the workpiece is held between two grinding wheels a regulating wheel and a grinding wheel. The regulating wheel controls the rotational speed and feeds the workpiece through the grinding wheel, ensuring uniformity. This technique offers several advantages over traditional grinding methods, including higher productivity, reduced setup time, and the ability to grind multiple parts simultaneously.

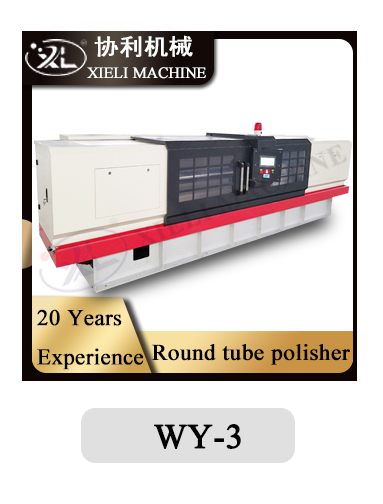

wholesale surface grinder centerless grinding

One of the distinct benefits of centerless grinding is its capacity for continuous operation, making it ideal for mass production. Additionally, due to the absence of a supporting fixture, this technique allows for greater flexibility in the types of materials and shapes that can be processed. This has made centerless grinding a preferred choice in the manufacturing of shafts, bearings, and other cylindrical components.

Combining Technologies

The combination of wholesale surface grinders and centerless grinding machines in manufacturing operations can lead to significant improvements in product quality and operational efficiency. By integrating both methods, manufacturers can ensure that their components not only meet the required dimensions but also exhibit superior surface finishes.

Furthermore, the ability to procure these machines wholesale means that manufacturers can invest in high-quality equipment without breaking the bank. This opens up opportunities for small to mid-sized businesses to compete effectively in the market by leveraging advanced manufacturing technologies.

Conclusion

In conclusion, the importance of wholesale surface grinders and centerless grinding in manufacturing cannot be overstated. As industries continue to push for higher quality and faster production rates, these grinding technologies will remain integral to achieving these goals. By investing in efficient grinding solutions, manufacturers can ensure that they meet the ever-growing demands of modern production while maintaining stringent quality standards.