The Importance of Wholesale Metal Surface Polishing Machines in Modern Manufacturing

In the rapidly evolving world of manufacturing and metalworking, the quality of the final products is paramount. One vital aspect of this quality is the surface finish of the metals used. To achieve a high standard of surface finish, manufacturers increasingly rely on metal surface polishing machines. Particularly in the wholesale market, these machines are essential for companies seeking to enhance their production efficiency and product quality. This article explores the significance of wholesale metal surface polishing machines, their types, benefits, and applications.

Understanding Metal Surface Polishing Machines

Metal surface polishing machines are specialized industrial tools designed to create a smooth and reflective surface on metal objects. These machines remove imperfections, such as scratches and oxidation, to ensure the metal surface is polished to the desired finish. They are used in various industries, including automotive, aerospace, construction, and consumer goods manufacturing, where aesthetics and performance are critical.

Types of Metal Surface Polishing Machines

There are several types of metal surface polishing machines available in the wholesale market

1. Belt Polishers These machines use abrasive belts to achieve a high-gloss surface on metal components, making them ideal for medium to large-scale production.

2. Disc Polishers Utilizing rotating discs, these machines provide precise polishing for intricate designs and smaller items. They are suitable for achieving a mirror finish on various metal surfaces.

3. Vibratory Polishers This type of machine uses vibrational motion to polish metal parts, making it effective for batch processing and finishing complex shapes.

4. CNC Polishers Computer Numerical Control (CNC) polishers offer automated polishing solutions, allowing for high precision and repeatability in the polishing process. This is particularly important in industries that require exact specifications.

Benefits of Using Metal Surface Polishing Machines

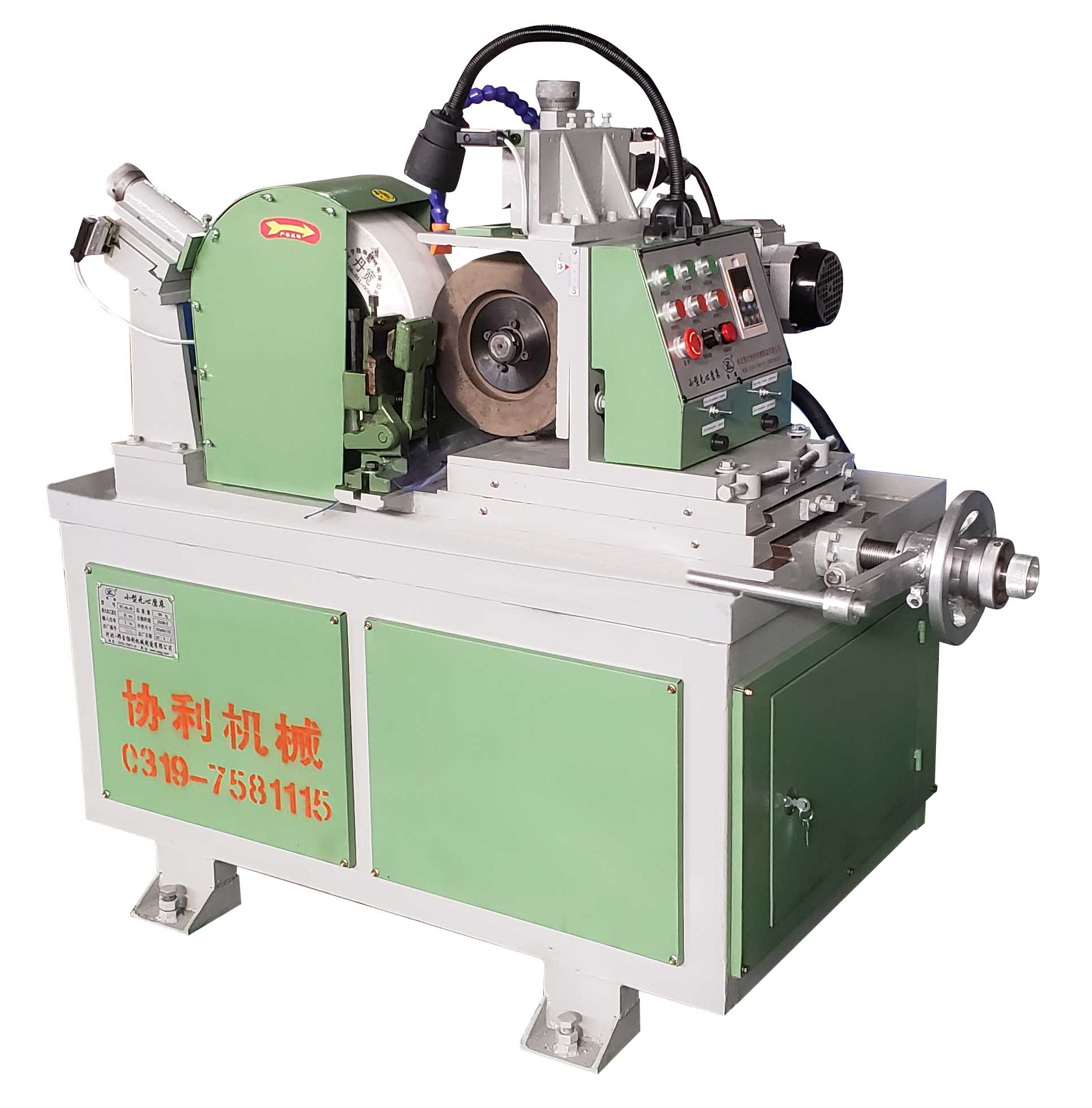

wholesale metal surface polishing machine

Utilizing wholesale metal surface polishing machines offers numerous advantages for manufacturers

1. Enhanced Product Quality A polished surface not only improves the aesthetic appeal of metal products but also enhances their functionality. A smooth surface can reduce friction, making components more efficient in mechanical applications.

2. Increased Durability Polishing machines help to remove contaminants and imperfections that can lead to corrosion. By ensuring a proper finish, the lifespan of metal products can be significantly increased.

3. Cost-Effectiveness Investing in high-quality wholesale polishing machines can lead to significant cost savings over time. They streamline the manufacturing process, reduce labor costs, and minimize waste by ensuring that products meet the required specifications from the outset.

4. Versatility Metal surface polishing machines can accommodate a wide range of materials, including stainless steel, aluminum, brass, and more. This versatility makes them an invaluable asset for manufacturers dealing with various metal products.

5. Increased Productivity With advanced technology and automation, modern polishing machines enhance productivity by reducing the time spent on manual polishing. This allows manufacturers to produce higher volumes of polished products in less time.

Applications in Various Industries

The applications of metal surface polishing machines are vast and cover multiple industries. In the automotive sector, for instance, polished parts not only contribute to the vehicle's aesthetics but also improve performance by reducing drag and enhancing fuel efficiency. In the aerospace industry, precision polishing is critical for components that demand strict adherence to specifications to ensure safety and functionality.

In consumer goods manufacturing, polished metal items—ranging from kitchen appliances to decorative hardware—bolster consumer appeal through their visual quality. Similarly, in architecture, polished metal surfaces are essential for achieving modern design aesthetics in buildings and public spaces.

Conclusion

In summary, wholesale metal surface polishing machines represent a crucial investment for manufacturers looking to enhance the quality and efficiency of their production processes. These machines not only improve the aesthetic and functional qualities of metal products but also contribute to greater productivity and durability. As industries continue to evolve, the significance of these polishing machines in achieving high-quality finishes will remain paramount. Investing in the right equipment can lead to substantial long-term benefits, ensuring that manufacturers remain competitive in an ever-changing marketplace.