The Importance of Wholesale Centerless Valve Grinders

In the ever-evolving landscape of manufacturing and engineering, precision and efficiency are paramount. One of the critical components in achieving these goals is the use of high-quality machinery, specifically centerless valve grinders. For businesses looking to produce valves with exceptional precision, wholesale centerless valve grinders serve as a vital tool in their operations.

Centerless grinding is a machining process that uses a grinding wheel and a regulating wheel to grind the workpiece without the need for a fixture. This method is particularly beneficial for manufacturing valve components, as it allows for a highly efficient and precise grinding operation. Centerless valve grinders can produce components with tighter tolerances and smoother finishes compared to traditional grinding methods.

One of the significant advantages of purchasing centerless valve grinders from wholesale suppliers is the cost-effectiveness. Wholesale pricing allows manufacturers to acquire the necessary machinery at reduced costs, enabling them to allocate more resources to other critical areas of production. This is especially vital for small to medium-sized enterprises (SMEs) that may have limited budgets but still require high-quality equipment to remain competitive.

wholesale centerless valve grinder

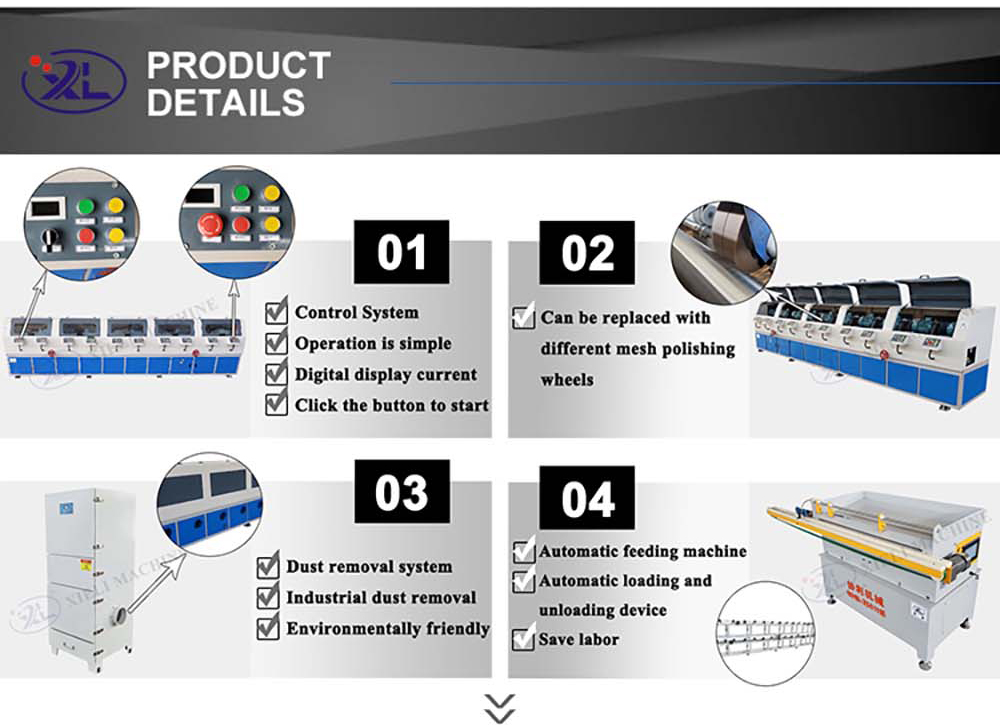

Moreover, wholesale suppliers often provide a variety of models that cater to different production needs. From basic models suitable for small-scale operations to advanced machines equipped with the latest technology for high-volume production, businesses can find the perfect grinder that fits their specific requirements. Additionally, many wholesale suppliers offer customization options, allowing companies to modify their equipment according to their operational needs.

When investing in a centerless valve grinder, it is crucial to consider factors such as the machine's efficiency, durability, and ease of use. High-quality grinders are built with robust materials and advanced engineering techniques, which ensures longevity and reliability in harsh manufacturing environments. Furthermore, modern machines often come equipped with user-friendly interfaces and automated features, reducing the learning curve for operators and minimizing the chance of errors during production.

After-sales support is another critical aspect to consider when sourcing from wholesale suppliers. Comprehensive support services, including maintenance, repair, and parts replacement, are essential for keeping the machinery running smoothly and extending its lifespan. Reputable suppliers typically offer warranties and support packages that enhance the overall value of the investment.

In conclusion, wholesale centerless valve grinders play a crucial role in the manufacturing industry, particularly for businesses focused on producing precise valve components. By offering cost-effective solutions, varied models, and comprehensive support, wholesale suppliers empower manufacturers to enhance their production capabilities. Investing in these advanced machines not only boosts efficiency but also ensures that companies can meet the ever-increasing demands of their clients in a competitive market.