The Importance of Wholesale Centerless Finish Grinders in Manufacturing

In the world of manufacturing, precision and efficiency are paramount. One of the key tools that has emerged as essential in achieving these goals is the centerless finish grinder. Specifically designed for high-volume production, these machines offer unmatched accuracy and surface finish quality. This article will explore the significance of wholesale centerless finish grinders and their impact on various industries.

What is a Centerless Finish Grinder?

A centerless finish grinder is a specialized type of grinding machine that is primarily used to grind cylindrical surfaces. Unlike traditional grinders that use centers to hold the workpiece in place, centerless grinders utilize a system of wheels to support and grind the piece without the need for any mounting. This unique setup allows for continuous grinding operations, making them ideal for high-output manufacturing environments.

How Centerless Grinders Work

The fundamental operation of a centerless grinder involves three major components the grinding wheel, the regulating wheel, and the workpiece. The grinding wheel is responsible for removing material from the workpiece, while the regulating wheel controls the speed and position of the workpiece as it moves through the grinder.

Typically, the workpiece is fed into the grinder and supported by a work rest blade. The regulating wheel rotates the workpiece against the grinding wheel, which removes material to achieve the desired diameter and finish. This method offers several advantages, including improved consistency, reduced grinding times, and the ability to process a variety of materials effectively.

Advantages of Wholesale Centerless Finish Grinders

1. Cost Efficiency Purchasing centerless finish grinders in bulk can lead to significant cost savings for manufacturers. Wholesale pricing allows businesses to acquire multiple machines at a reduced rate, enabling them to scale up production without a substantial financial burden.

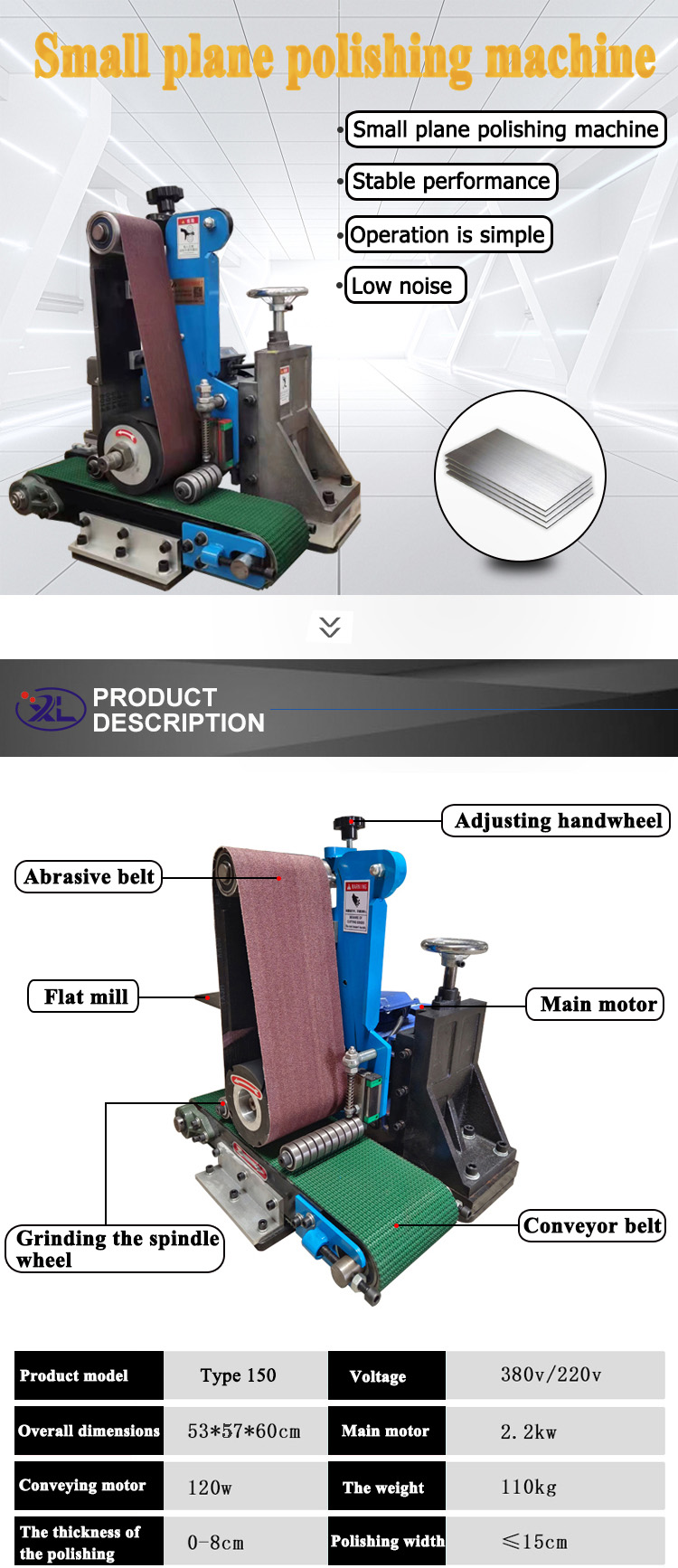

wholesale centerless finish grinder

2. High Precision and Quality One of the most notable benefits of centerless grinding is its ability to produce parts with extreme precision. The continuous grinding action ensures a uniform finish, which is critical in industries like automotive and aerospace, where even the slightest variance can lead to malfunction.

3. Enhanced Productivity Centerless grinders can operate at high speeds, drastically reducing the time required for machining processes. This increased throughput is particularly valuable in an industrial setting where time is money. Machines can be set up for unattended operation, further enhancing productivity.

4. Versatility These grinders can handle a wide range of materials and sizes, making them suitable for various applications. From simple rods to more complex components, centerless grinders can accommodate different shapes, profiles, and finishes.

5. Reduced Labor Costs The automation capabilities of modern centerless grinders minimize the need for manual intervention. This reduction in labor not only cuts costs but also decreases the risk of human error, leading to higher quality products.

Industries That Benefit from Centerless Finish Grinders

Several industries rely heavily on centerless finish grinders for their production needs. The automotive sector utilizes these machines for manufacturing components like shafts, bearings, and valve guides. The aerospace industry also benefits from the precision offered by centerless grinding, using it for parts that require stringent quality standards.

Moreover, companies in the medical field use centerless grinders to produce tools and implants that demand high precision and reliability. Even within the electronics industry, where miniaturization is key, centerless grinding enables the production of miniature parts with tight tolerances.

Conclusion

Wholesale centerless finish grinders represent a critical investment for manufacturers seeking to enhance efficiency, precision, and overall production quality. Their ability to reduce costs, improve productivity, and ensure superior finishes makes them an invaluable tool across many industries. As manufacturing demands continue to evolve, embracing advanced machining technologies like centerless grinding will be essential for companies aiming to stay competitive in the ever-changing landscape of production. The shift towards automated and efficient solutions underscores the role of wholesale centerless finish grinders as a cornerstone in modern manufacturing practices.