The Importance of Wholesale Bend Tube Polishing Machines in Modern Manufacturing

In today's competitive manufacturing environment, efficiency and quality are paramount. Among the various tools and machines that fabricators rely on, the bend tube polishing machine plays a crucial role, especially in industries that require high standards of finish and precision. The increasing demand for seamless and aesthetically pleasing metal products has made wholesale bend tube polishing machines an essential asset in many manufacturing facilities.

What is a Bend Tube Polishing Machine?

A bend tube polishing machine is specifically designed to polish bent tubes, which are commonly used in various applications ranging from automotive exhaust systems to furniture design and industrial piping. These machines are engineered to provide a consistent finish, effectively removing scratches, oxidation, and other surface imperfections. By utilizing specialized polishing heads and abrasive materials, these machines can achieve a mirror-like finish that enhances both the appearance and durability of the metal.

Benefits of Wholesale Purchasing

Businesses looking to invest in bend tube polishing machines often consider wholesale purchasing options. Buying in bulk not only significantly reduces costs but also allows companies to acquire multiple machines, thus increasing production capacity. This is particularly beneficial for larger facilities or those operating multiple production lines. Manufacturers can negotiate favorable terms with suppliers, gaining access to the latest technology and features at a more affordable price.

Enhanced Efficiency and Productivity

One of the primary advantages of using bend tube polishing machines is the enhancement of operational efficiency. Traditional polishing methods are labor-intensive and may not deliver the uniform results required in modern manufacturing. In contrast, automated polishing machines can process tubes quickly and with precision. This efficiency translates to higher throughput and allows businesses to meet tight deadlines without sacrificing quality.

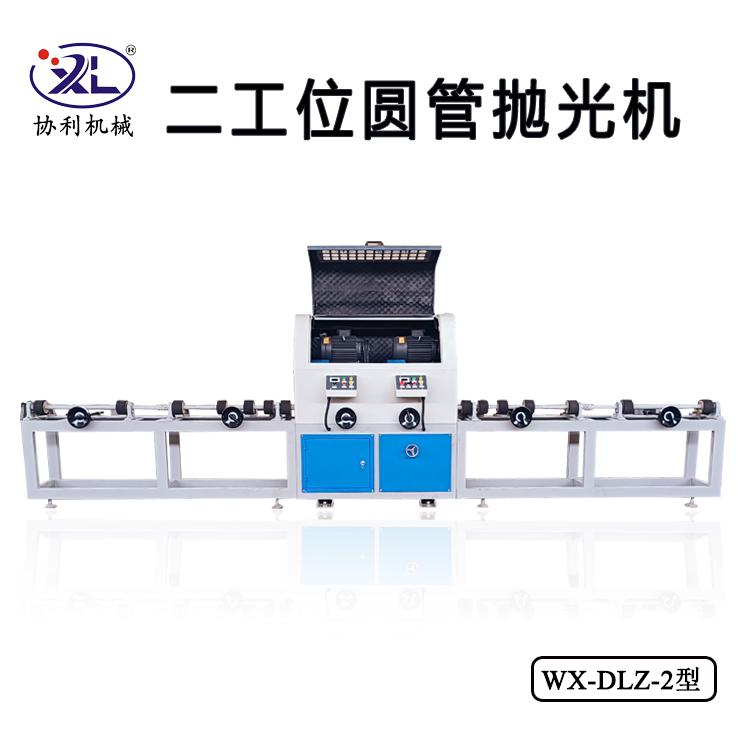

wholesale bend tube polishing machine

Quality Assurance

In industries such as aerospace, automotive, and medical manufacturing, the quality of metal components is non-negotiable. Bend tube polishing machines ensure that each piece meets stringent standards. The consistency achieved through machine polishing minimizes human error and variability, enabling manufacturers to provide reliable products that meet or exceed industry specifications. Moreover, a well-polished tube not only looks better but also performs better by reducing friction and corrosion over time.

Versatility of Use

Bend tube polishing machines are highly versatile and can accommodate various materials, including stainless steel, aluminum, copper, and brass. As different industries have their unique requirements, the adaptability of these machines allows manufacturers to diversify their product offerings without significant additional investment. Many models come equipped with adjustable settings to handle different tube diameters and shapes, making them suitable for a wide range of applications.

Environmental Considerations

Modern bend tube polishing machines are designed with environmental consciousness in mind. Many models now feature closed-loop systems that minimize waste and reduce the ecological footprint of manufacturing processes. Additionally, the use of efficient polishing materials reduces the need for chemical treatments that can be harmful to the environment. By investing in environmentally friendly equipment, manufacturers not only comply with regulatory standards but also enhance their corporate social responsibility.

Conclusion

In summary, wholesale bend tube polishing machines are an indispensable part of modern manufacturing. They offer unparalleled efficiency, ensure high-quality finishes, and provide businesses with the versatility needed to thrive in a dynamic market. By investing in these machines, companies can improve their production capabilities and achieve the high-quality results that customers demand. As the industry continues to evolve, the importance of quality polishing in the fabrication process will only increase, making these machines a critical component of success for manufacturers across various sectors. Whether you're a small shop or a large-scale operation, the right bend tube polishing machine can elevate your production processes and contribute to your overall business success.