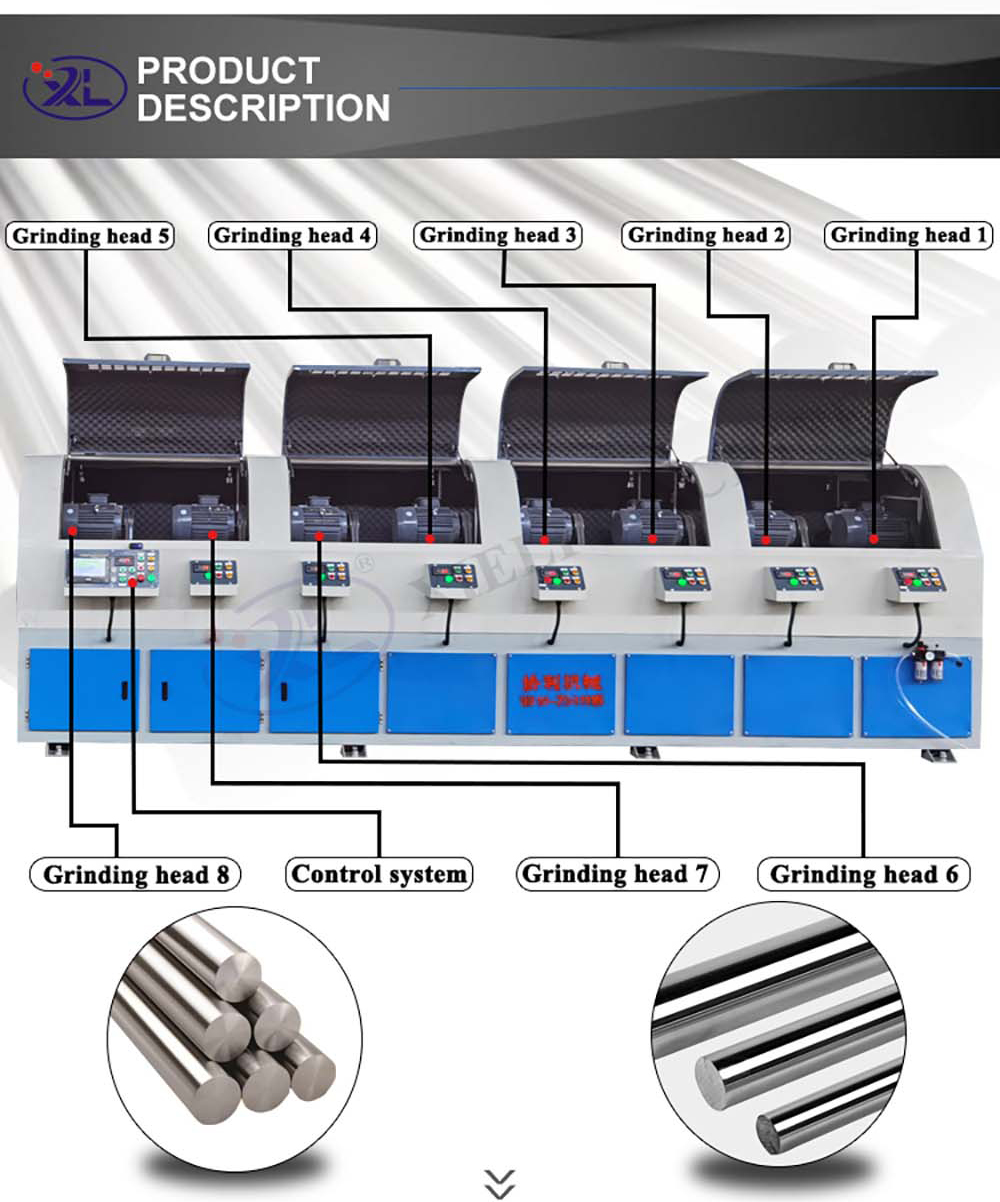

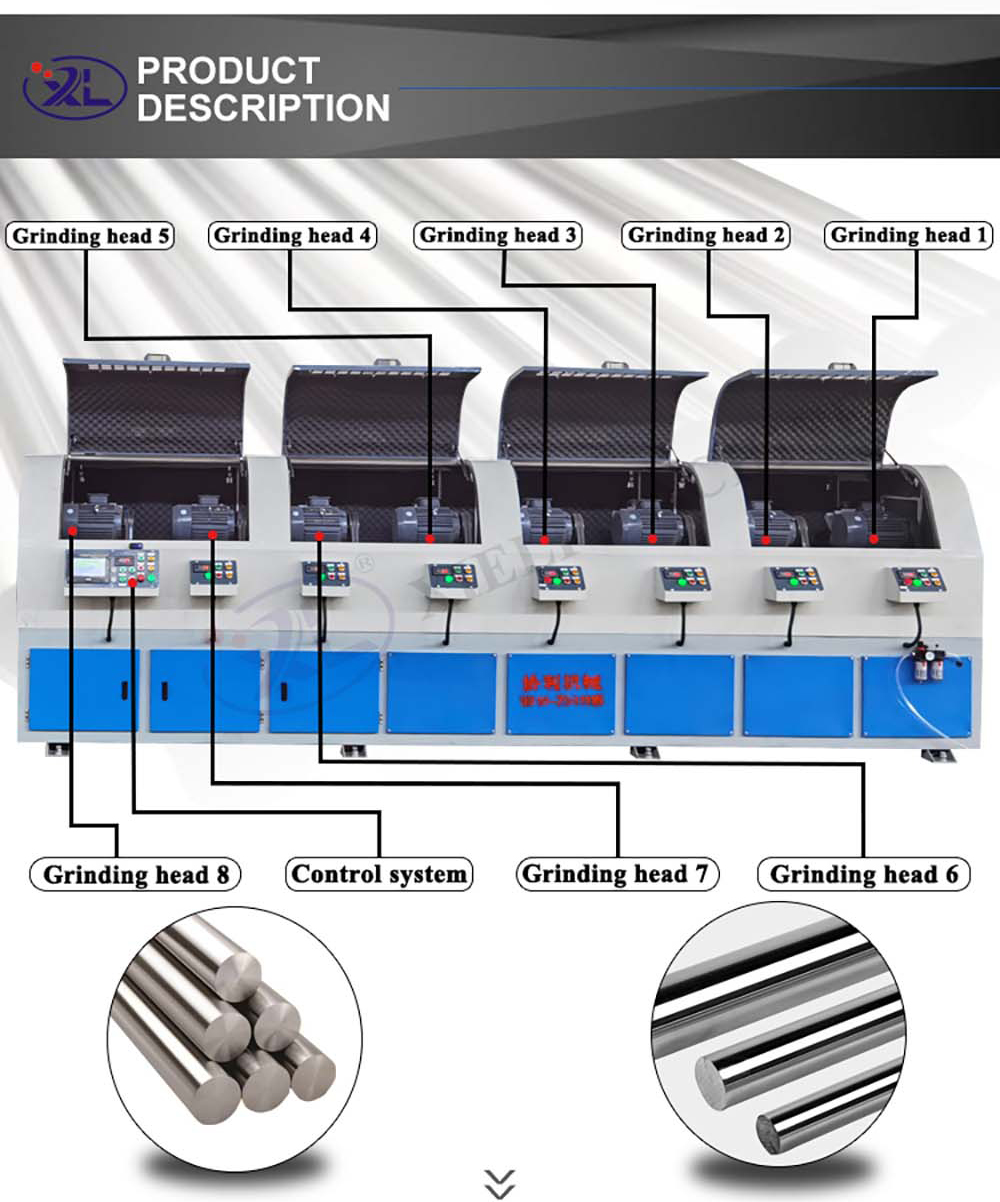

With interchangeable grinding wheels and adjustable speeds, they can accommodate a wide range of materials and part sizes With interchangeable grinding wheels and adjustable speeds, they can accommodate a wide range of materials and part sizes

With interchangeable grinding wheels and adjustable speeds, they can accommodate a wide range of materials and part sizes With interchangeable grinding wheels and adjustable speeds, they can accommodate a wide range of materials and part sizes wholesale infeed centerless grinder. From hardened steels to delicate ceramic components, these grinders are optimized for various applications, ensuring that businesses can diversify their product lines without significant additional investment in machinery.

Moreover, the automation capabilities of modern wholesale infeed centerless grinders have revolutionized mass production techniques. Advanced models feature automatic loading and unloading systems, reducing labor costs and improving safety by minimizing operator contact with moving parts. Intelligent controls and feedback systems further enhance process monitoring, allowing for real-time adjustments to maintain optimal grinding conditions.

In conclusion, the wholesale infeed centerless grinder represents a pinnacle of efficiency and flexibility in the manufacturing sector. Its ability to deliver consistent quality at high volumes has made it an essential piece of equipment for those seeking to streamline operations and increase output. As technology continues to advance, it is likely that these grinders will become even more sophisticated, further cementing their status as a cornerstone of modern industry.

wholesale infeed centerless grinder. From hardened steels to delicate ceramic components, these grinders are optimized for various applications, ensuring that businesses can diversify their product lines without significant additional investment in machinery.

Moreover, the automation capabilities of modern wholesale infeed centerless grinders have revolutionized mass production techniques. Advanced models feature automatic loading and unloading systems, reducing labor costs and improving safety by minimizing operator contact with moving parts. Intelligent controls and feedback systems further enhance process monitoring, allowing for real-time adjustments to maintain optimal grinding conditions.

In conclusion, the wholesale infeed centerless grinder represents a pinnacle of efficiency and flexibility in the manufacturing sector. Its ability to deliver consistent quality at high volumes has made it an essential piece of equipment for those seeking to streamline operations and increase output. As technology continues to advance, it is likely that these grinders will become even more sophisticated, further cementing their status as a cornerstone of modern industry.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.