Viking Centerless Grinder for Sale A Complete Solution for Precision Machining

In the world of precision machining, the tools and technology employed can make all the difference. Among these tools, the centerless grinder stands out as a vital component in achieving the perfect finish on cylindrical parts. One company making waves in this arena is Viking, known for its high-quality centerless grinders. This article delves into the features, benefits, and buying considerations for Viking centerless grinders for sale.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that efficiently grinds and finishes materials without the need for supports. Unlike traditional grinding machines, where the workpiece is supported at both ends, the centerless grinder has a designated workpiece setup that holds it in place using two rotating wheels. This unique design allows for faster operation and higher efficiency, making it an ideal choice for mass production and precision machining.

Features of Viking Centerless Grinders

Viking centerless grinders are renowned for their robust design and advanced features

1. High Precision These grinders are engineered to offer exceptional precision in machining. They're capable of achieving tight tolerances, ensuring that each manufactured part meets exact specifications.

2. Durability Built with high-quality materials, Viking grinders are designed to withstand the rigors of continuous operation. Their reliability means less downtime and lower maintenance costs, making them a favorite among manufacturers.

3. Versatility Viking centerless grinders are equipped to handle a variety of materials, including metals, plastics, and composites. This versatility makes them suitable for diverse applications across different industries, including automotive, aerospace, and medical devices.

4. Customizable Settings Different production runs may require specific grinding conditions. Viking centerless grinders often come with customizable settings for speed, pressure, and alignment, allowing operators to fine-tune their processes to achieve optimal results.

5. User-Friendly Interface Most models come with intuitive controls that make it easier for operators to set up and monitor the grinding process. This user-friendly design reduces the learning curve and boosts overall productivity for businesses.

Benefits of Investing in a Viking Centerless Grinder

Investing in a Viking centerless grinder can yield significant advantages for machining businesses

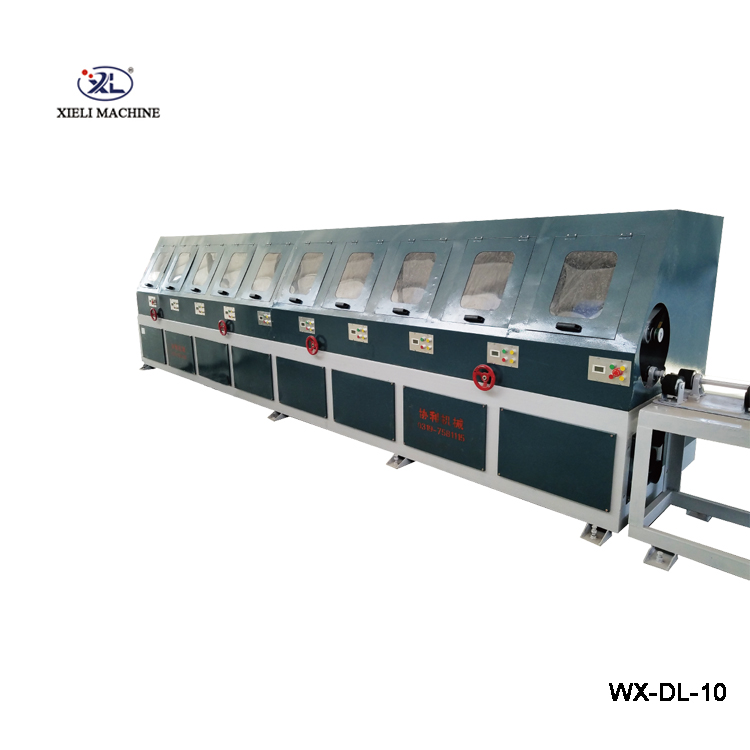

viking centerless grinder for sale company

- Increased Efficiency With their ability to process multiple workpieces simultaneously, Viking grinders streamline production processes. This efficiency translates to lower operational costs and higher output.

- Superior Surface Finish The precision offered by these machines often results in superior surface finishes, significantly improving the quality of the final product. This factor can be crucial in industries where aesthetics or performance are paramount.

- Cost-Effective Solution While the initial investment in a quality grinder might be substantial, the long-term savings gained from reduced labor costs, lower material waste, and less downtime make it a wise choice.

- Enhanced Competitive Edge In a rapidly evolving market, businesses that utilize advanced machinery like Viking centerless grinders can stay ahead of the competition. Their speed and precision can enable companies to deliver superior products faster than their competitors.

How to Choose the Right Viking Centerless Grinder

When looking for a Viking centerless grinder for sale, there are several considerations to keep in mind

1. Production Volume Assess the volume of parts you need to produce. Classify models based on their output capabilities to ensure you select one suited for your production needs.

2. Material Type Different models cater to different materials. Consider the primary materials you will be working with to ensure compatibility.

3. Space Requirements Check the physical dimensions of the grinder and whether it will fit in your production area, keeping in mind requirements for ventilation and maintenance access.

4. Budget Like any major equipment purchase, establishing a budget is crucial. Investigate the total cost of ownership, including maintenance, before making a decision.

5. Customer Support Look for reputable suppliers who provide after-sales support, including installation, training, and maintenance services.

Conclusion

In conclusion, Viking centerless grinders represent a powerful solution for companies seeking to enhance their precision machining capabilities. Their high efficiency, durability, and superior finish quality make them a valuable investment for any manufacturing operation. By understanding the specific requirements of your production process, you can be well-equipped to choose the right Viking centerless grinder for your needs.