Custom Flat Polishing Machine Revolutionizing Surface Finishing

In today's manufacturing landscape, precision and efficiency are paramount. Among the numerous processes that contribute to the production of high-quality components, surface finishing is crucial. A custom flat polishing machine stands out as an indispensable tool in achieving superior surface quality, particularly for flat components that require a flawless finish. This article explores the significance and advantages of custom flat polishing machines, as well as their applications across various industries.

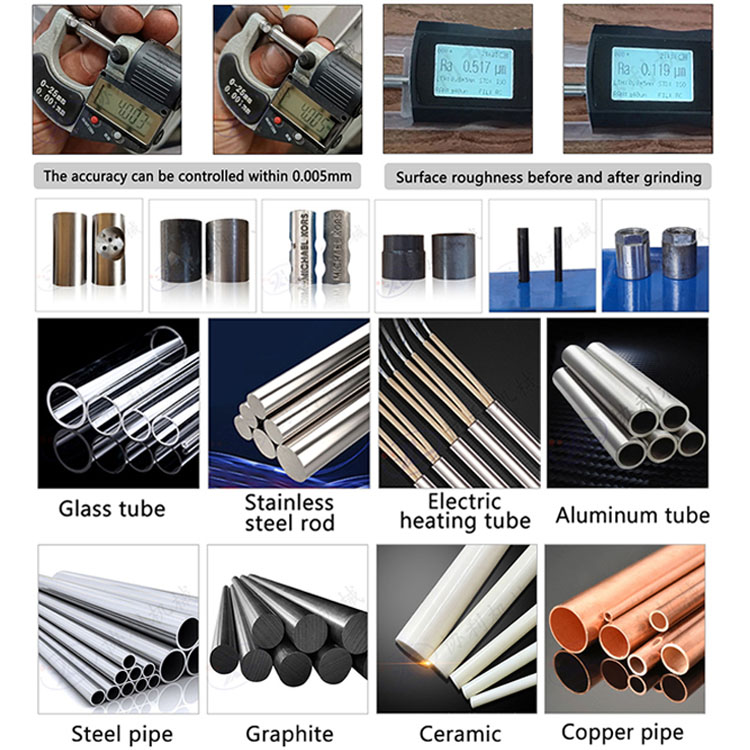

A custom flat polishing machine is engineered to meet specific operational requirements, tailored to fit the unique demands of different materials and surface finishing goals. These machines utilize advanced technology to polish surfaces smoothly, eliminating imperfections, enhancing aesthetic appeal, and improving overall performance. From intricate components in the aerospace industry to fundamental parts in consumer electronics, a custom flat polishing machine offers unparalleled versatility.

Enhanced Efficiency and Precision

One of the primary advantages of utilizing a custom flat polishing machine is the enhanced efficiency it brings to the manufacturing process. Traditional polishing methods can be time-consuming and labor-intensive, often leading to inconsistent results. In contrast, modern polishing machines are designed to automate and streamline the process. They can handle large volumes of parts with minimal human intervention, reducing labor costs and increasing throughput.

Moreover, these machines are equipped with advanced control systems that ensure precise polishing parameters are consistently maintained. This results in uniform surface finishes with minimal variations, meeting the exact specifications required by the industry. The precision achieved through custom flat polishing machines not only elevates the quality of the final product but also minimizes the need for rework, saving both time and resources.

Customization for Specific Applications

custom flat polishing machine

The versatility of custom flat polishing machines allows them to be tailored for specific applications. Manufacturers can specify the size, shape, and material of the components they need to polish, as well as the desired surface finish. For instance, in the optics industry, where optical components must be polished to a specific standard, a customized machine can be designed to achieve the necessary clarity and smoothness.

Further customization can include the integration of various polishing techniques, such as three-dimensional contour polishing, belt polishing, or chemical mechanical polishing (CMP). This flexibility ensures that manufacturers can adapt to ever-changing market demands and technological advancements, making it easier to remain competitive.

Applications Across Various Industries

The applications of custom flat polishing machines span a diverse range of industries. In the semiconductor field, they are used for polishing silicon wafers to achieve the ultra-smooth surfaces needed for chip production. In metalworking, these machines can polish aluminum, steel, and other metals to create premium finishes that are not only visually appealing but also enhance corrosion resistance.

The automotive industry also benefits from custom flat polishing machines, particularly in the production of engine components and decorative trim parts. Additionally, in the medical sector, these machines are instrumental in manufacturing precision parts such as surgical tools and implants, where hygiene and precision are non-negotiable.

Conclusion

Investing in a custom flat polishing machine can significantly enhance a manufacturer’s operational capabilities. With their ability to provide high-quality finishes, enhance efficiency, and adapt to specific needs, these machines are transforming the landscape of surface finishing. As industries continue to evolve, the role of custom flat polishing machines will only grow, ensuring that manufacturers can meet the increasing demands for precision and quality in their products. By integrating such advanced machinery, companies can secure a competitive edge in an ever-challenging marketplace, paving the way for innovation and excellence in surface finishing technology.