Twin Grip Centerless Grinder A Revolution in Precision Grinding

In the realm of manufacturing and precision engineering, the pursuit of efficiency, accuracy, and quality is paramount. A vital tool that has consistently evolved to meet these demands is the centerless grinder. Among the various types of centerless grinding machines available today, the twin grip centerless grinder stands out as a remarkable innovation. This advanced machinery is specifically designed to enhance productivity while delivering unparalleled precision in the grinding process.

Understanding Twin Grip Centerless Grinding Technology

Centerless grinding is a machining process used to remove material from a workpiece, where the workpiece is not held in place by a centering mechanism, allowing for uninterrupted rotation. The twin grip design, as the name suggests, employs two gripping mechanisms, one at the front and one at the rear of the workpiece. This innovative setup ensures better stability and alignment during the grinding operation, leading to higher precision and improved surface finishes.

The twin grip centerless grinder is characterized by its ability to handle a variety of shapes and sizes, making it suitable for diverse manufacturing applications. This versatility is significantly beneficial in industries such as automotive, aerospace, and medical device manufacturing, where exactitude is crucial.

Key Features and Advantages

1. Enhanced Stability The dual grip design provides superior stability, minimizing the risk of deflection and maintaining consistent dimensions throughout the grinding process. This is particularly important for industries where tolerances are tight and surface quality is essential.

2. Increased Efficiency Twin grip centerless grinders allow for faster cycles and reduced setup times. The machines can accommodate different workpiece sizes without extensive reconfiguration, thus optimizing production flow and reducing downtime.

3. Improved Surface Finish The precision afforded by the twin grip mechanism enables manufacturers to achieve finer surface finishes. The controlled grinding process results in smoother surfaces, which is critical for components that require minimal friction in applications like bearings and shafts.

twin grip centerless grinder manufacturer

4. Versatile Applications From complex shapes to simple cylindrical parts, twin grip centerless grinders can effectively process a wide range of materials, including metals, plastics, and composites. This adaptability makes them essential in various sectors where multi-functional capabilities are valued.

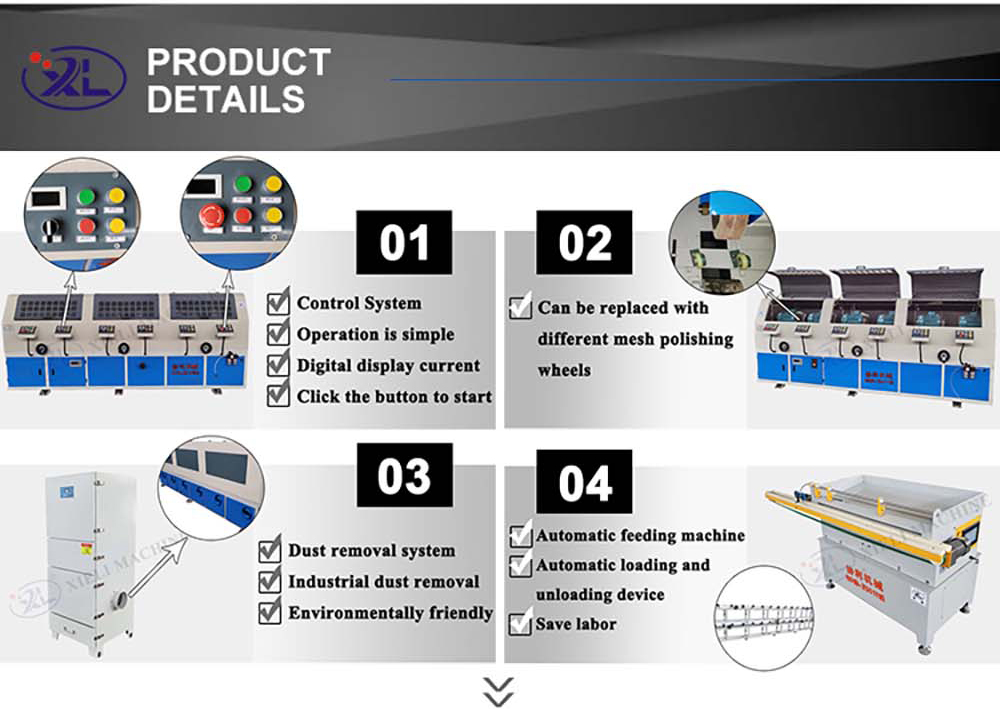

5. Reduced Operator Strain Many modern twin grip centerless grinders are designed with ergonomic considerations, making them easier to operate. Features such as automated loading and unloading systems reduce the physical strain on operators and enhance overall safety in the workplace.

The Future of Twin Grip Centerless Grinding

As industries continue to embrace automation and advanced manufacturing techniques, the future of twin grip centerless grinders looks promising. Manufacturers are continually innovating by incorporating smart technology, such as predictive maintenance, real-time monitoring, and data analytics into their grinding solutions. These advancements not only improve operational efficiency but also contribute to proactive problem solving, ensuring that machines remain in optimal working condition.

Moreover, the emphasis on sustainability in manufacturing processes has led to the development of eco-friendly grinding solutions. Twin grip centerless grinders are now being designed to minimize energy consumption and waste, aligning with the global push for greener practices in production.

Choosing the Right Manufacturer

Selecting the right manufacturer for twin grip centerless grinders is crucial for ensuring quality and reliability. Companies should consider factors such as the manufacturer's reputation, the technology used in their machines, customer support, and the availability of customization options to meet specific production needs.

In conclusion, twin grip centerless grinders represent a significant advancement in the field of precision grinding. With their enhanced stability, efficiency, and versatility, these machines are set to play a vital role in the future of manufacturing. As industries strive for higher quality standards and greater productivity, investing in a twin grip centerless grinder can provide the competitive edge that manufacturers need to stay ahead in today's market.