Twin Grip Centerless Grinder Revolutionizing Precision Grinding

In the realm of manufacturing, precision and efficiency are often the cornerstones of success. Among the various tools that contribute to achieving these goals, the twin grip centerless grinder stands out as a pivotal machine. This specialized piece of equipment enhances the grinding process, minimizing friction and ensuring an unparalleled level of accuracy. In this article, we will explore the significance, functionality, and advantages of twin grip centerless grinders, examining how they contribute to the modern manufacturing landscape.

What is a Centerless Grinder?

Centerless grinders represent a unique class of machinery distinct from traditional grinding equipment. Unlike conventional grinders, where the workpiece is held between two centers, a centerless grinder supports the workpiece via two wheels the grinding wheel and the regulating wheel. The absence of a center fixture allows for continuous operation and increased productivity, particularly when processing long, cylindrical parts.

The Twin Grip Mechanism

The twin grip centerless grinder takes this concept a step further by utilizing two opposing gripping mechanisms that provide enhanced stability and control over the workpiece. This design offers several advantages over standard centerless grinding machines, leading to improved dimensional accuracy and surface finish.

1. Enhanced Stability The twin grip design minimizes vibrations and oscillations during the grinding process. This stability is paramount, especially when working with tighter tolerances and advanced materials. The improved rigidity ensures that the workpiece remains in place, preventing errors that may arise from movement.

2. Increased Operational Efficiency By allowing for rapid loading and unloading of workpieces, twin grip centerless grinders enhance operational efficiency. This is particularly beneficial in high-volume production environments where time is of the essence. The ability to maintain a rapid cycle without sacrificing precision can lead to significant gains in productivity.

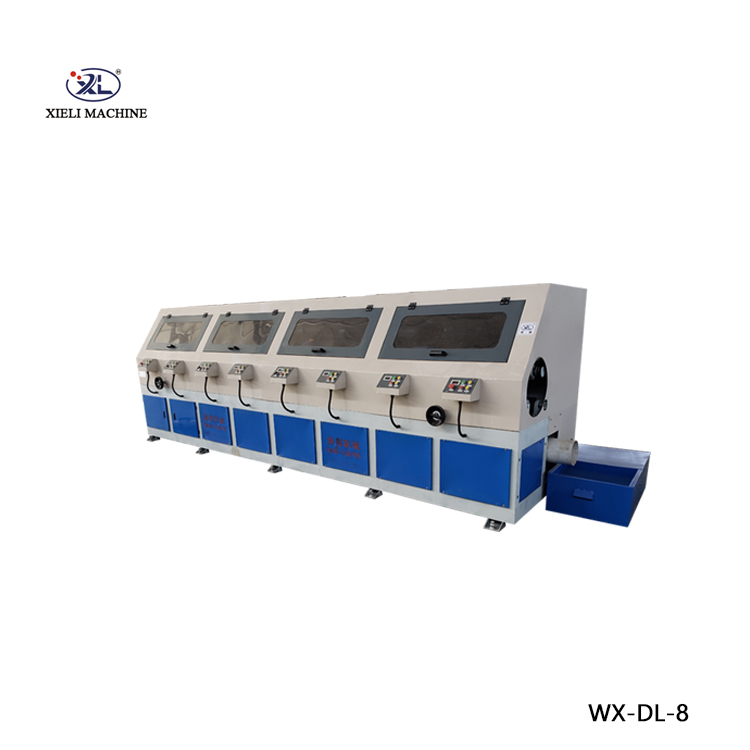

twin grip centerless grinder company

3. Versatility in Applications Twin grip centerless grinders are versatile and adaptable, making them suitable for a broad range of applications. Whether grinding shafts, rods, tubes, or specialized components, the twin grip mechanism can accommodate various sizes and shapes, providing manufacturers with a flexible solution tailored to their needs.

Applications Across Industries

The utility of twin grip centerless grinders extends across multiple industries, including automotive, aerospace, medical, and manufacturing. In the automotive sector, for instance, precision grinding is critical for components such as valves, bearings, and axles. The ability to achieve exact specifications with a superior surface finish is vital for ensuring both performance and safety.

In the aerospace industry, where weight and precision are paramount, twin grip centerless grinders play a crucial role in fabricating components that meet exacting standards. Similarly, in the medical field, where equipment must be sterile and precise, these grinders ensure that tools and implants are produced with the utmost accuracy.

Conclusion Embracing Innovation

As manufacturing processes evolve, the need for more sophisticated and efficient tools becomes increasingly evident. The twin grip centerless grinder exemplifies the advances in engineering technology that cater to this demand. By combining enhanced stability, increased productivity, and versatility, these machines have carved a niche in the competitive landscape of industrial machinery.

Investing in twin grip centerless grinding technology not only ensures superior product quality but also positions manufacturers to meet the challenges of a dynamic market landscape. As industries continue to push the boundaries of innovation, embracing tools like twin grip centerless grinders will be essential for companies aiming to enhance their operational capabilities and uphold stringent quality standards.

In conclusion, the twin grip centerless grinder represents more than just a piece of machinery; it embodies a commitment to precision and efficiency that drives success on the factory floor. With its ability to adapt to various applications and continuously yield exceptional results, it is clear that this technology will play a critical role in shaping the future of manufacturing for years to come.