The Growing Demand for Tube Polishing Machine Products Exporters

In recent years, the global marketplace has seen a significant surge in the demand for tube polishing machines. These specialized machines play a crucial role in various industries, including metalworking, manufacturing, and construction where metal tubes require a polished finish for aesthetic, functional, and regulatory reasons. As a result, tube polishing machine products exporters are experiencing a boom, driven by technological advancements, international trade dynamics, and the relentless pursuit of quality in production processes.

One of the key factors contributing to the rising demand for tube polishing machines is the increasing standards of quality and precision in manufacturing. Industries involved in producing automotive parts, aerospace components, and high-end decorative items require that their metal tubes exhibit exceptional surface quality. Tube polishing machines offer a range of polishing techniques, including mechanical, chemical, and electrochemical processes, which can cater to various metallurgies and desired finishes. Exporters specializing in these machines are thus well-positioned to meet the specific needs of diverse industrial clients.

Moreover, globalization has opened new markets for tube polishing machine products exporters. Countries with burgeoning manufacturing sectors are seeking reliable and efficient machinery to enhance their production capabilities. Exporters are able to cater to these demands by providing state-of-the-art technology that ensures consistency and efficiency in polishing operations. Regions like Southeast Asia, South America, and parts of Eastern Europe are witnessing significant growth in their industrial segments, leading to increased procurement of advanced tube polishing machinery.

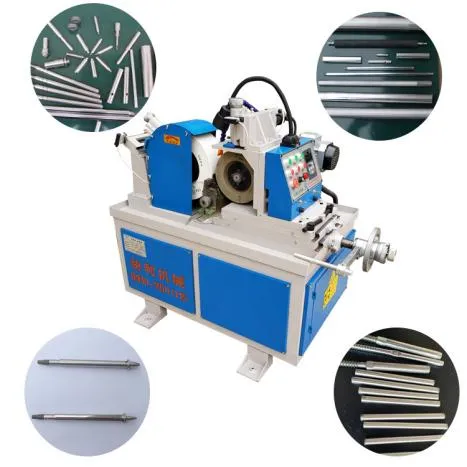

tube polishing machine products exporter

The role of technology in this sector cannot be overlooked. Innovations such as automation and computer numerical control (CNC) have revolutionized tube polishing processes, allowing for higher precision and speed in operations. Exporters who invest in cutting-edge technology can offer machines that not only improve product quality but also enhance operational productivity. This technological edge enables companies to remain competitive in a fast-evolving market, ensuring they deliver value to their customers.

Additionally, sustainability is becoming a cornerstone of modern manufacturing, pushing tube polishing machine products exporters to focus on energy-efficient and environmentally friendly machinery. These advancements not only help companies comply with regulations but also appeal to environmentally conscious consumers. Exporters that prioritize sustainability in their product offerings are likely to gain a foothold in the market, attracting clients who are committed to reducing their ecological footprint.

In conclusion, the demand for tube polishing machine products exporters is on the rise, fueled by high-quality manufacturing standards, globalization, technological innovations, and a commitment to sustainability. As industries continue to evolve and seek solutions for improved efficiency and quality, exporters of tube polishing machines stand to benefit immensely, playing a critical role in shaping the future of manufacturing worldwide.