Tube Polishing Machine for Sale A Guide to Choosing the Right Factory

In the manufacturing industry, the importance of maintaining high standards of quality and aesthetics cannot be overstated. Tube polishing machines play a vital role in the processing of metal tubes, ensuring that they not only meet the required specifications but also possess an appealing finish. For businesses looking to invest in tube polishing machines, understanding the market and knowing how to choose the best factory for your needs is essential. This article will discuss the various features to consider when searching for tube polishing machines for sale from reputable factories.

Understanding Tube Polishing Machines

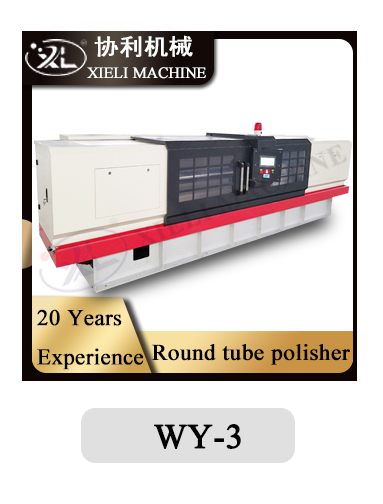

Tube polishing machines are specialized equipment designed to polish the surface of tubes made from metals such as stainless steel, aluminum, and brass. The primary function of these machines is to remove scratches, oxidation, and other imperfections, resulting in a smooth, shiny surface that enhances the product's overall appearance and prevents corrosion. These machines vary in size, speed, and technology, making it crucial for buyers to understand their specific polishing requirements.

Key Features to Look for in Tube Polishing Machines

1. Type of Machine There are several types of tube polishing machines available in the market, including manual, automatic, and CNC (Computer Numerical Control) models. Manual machines require more operator intervention, while automatic and CNC machines offer greater precision and efficiency. Depending on the production volume and budget, businesses should assess which type of machine best fits their needs.

2. Size and Capacity The dimensions and capacity of the tube polishing machine are critical factors to consider. If your business processes a variety of tube sizes, it may be beneficial to invest in a machine that can accommodate different diameters and lengths. Additionally, the machine’s throughput—how many tubes can be polished in a specific timeframe—will impact production efficiency.

3. Polishing Techniques Various polishing techniques, such as belt polishing, brush polishing, and electro-polishing, can be utilized depending on the desired finish. It's essential to choose a machine that can employ the right technique for your application. The versatility to switch between different polishing methods can offer significant advantages for manufacturers who work with diverse products.

tube polishing machine for sale factory

4. Quality of Components The longevity and performance of a tube polishing machine largely depend on the quality of its components. Machines constructed from high-quality materials and equipped with durable motors will generally perform better and require less maintenance over time. Always ask the manufacturer about the materials used and warranty options available.

5. Ease of Use and Maintenance A user-friendly interface and straightforward operation are vital for minimizing training time and maximizing productivity. Additionally, look for machines that are easy to clean and maintain. Regular maintenance is crucial for ensuring the machine operates efficiently over the long term.

6. Supplier Reputation Before purchasing a tube polishing machine, it's essential to research the reputation of the factory or supplier. Look for established manufacturers with a proven track record in the industry. Reading customer reviews and testimonials can provide insights into the quality of their products and services.

7. After-Sales Support Reliable after-sales support is a crucial aspect of your purchasing decision. A reputable factory will offer comprehensive support, including installation, training, and ongoing technical assistance. Being able to resolve any issues swiftly can save your business time and money.

Conclusion

Investing in a tube polishing machine can significantly enhance your production capabilities and the quality of your final products. By understanding the various features and factors involved in selecting the right machine and factory, companies can make informed decisions that align with their operational goals. Take the time to assess your specific requirements, explore different machines and suppliers, and ultimately choose a product that meets your needs while delivering the performance and quality you expect.

Whether you are a small workshop or a large manufacturing facility, the right tube polishing machine can elevate your production process, providing you with the edge needed in today’s competitive market.