Tube grinding machines are at the heart of many industries where precision and efficiency are critical. These machines are engineered to refine the surface of tubes, enhancing their performance and lifespan in applications ranging from automotive manufacturing to construction and even aerospace. Their prominence in the industrial sector stems from their unparalleled ability to consistently produce smooth and uniform surfaces, essential for high-performance applications.

A crucial component of tube grinding machines is their adaptability to various types of metals. Whether dealing with stainless steel, aluminum, or even more exotic metals, these machines are crafted to handle a diverse range of materials while delivering precise and reliable results. This versatility ensures that manufacturers can rely on a single machine for multiple projects, optimizing their investment and reducing downtime.

Moreover, the expertise required to operate tube grinding machines underscores their sophisticated design. Operators must learn various techniques, from setting the correct speeds for different materials to ensuring the tubes are securely clamped during the grinding process. This expertise not only enhances the safety of operations but also maximizes the quality of the finished product. Over time, experienced operators can fine-tune these machines to squeeze out the maximum efficiency, thereby increasing throughput without compromising on quality.

From a technical standpoint, the strategic incorporation of advanced features, such as CNC controls and automatic feeding systems, elevates the authoritativeness of tube grinding machines. CNC (Computer Numerical Control) systems bring a new dimension of precision to the operations, enabling detailed programming of grinding tasks to achieve minute specifications that might be impossible with manual operation. The automatic feeding systems further enhance productivity by managing the supply of tubes through consistent, autonomous cycles.

Trustworthiness is intrinsic to the operation of tube grinding machines, firmly seated in the consistent and superior quality of output one can expect. Manufacturers invest heavily in quality control measures to ensure each machine meets industry standards before they reach the marketplace. This includes meticulous testing of the machines under various conditions, assuring end-users of their durability and reliability across different environments.

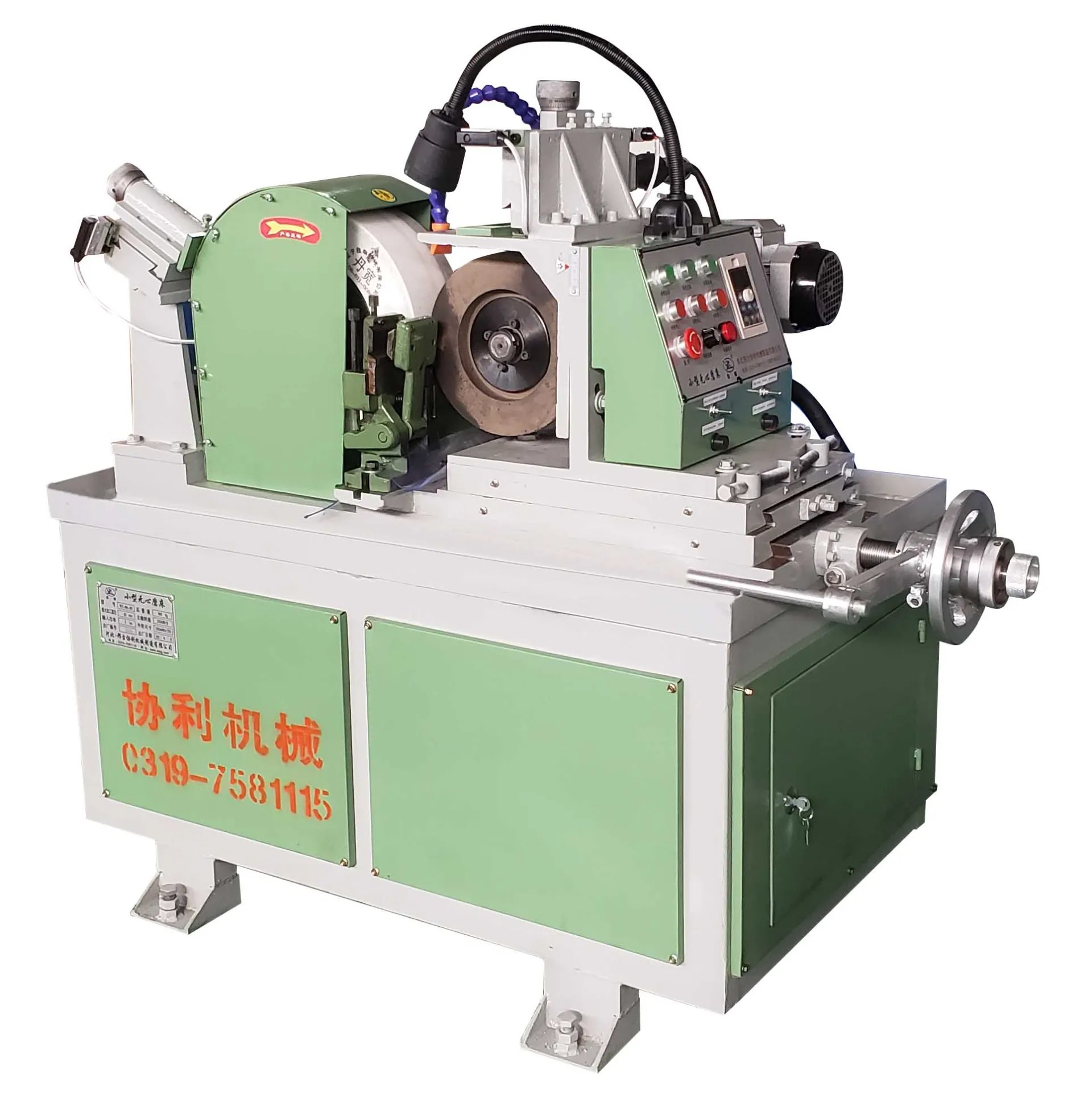

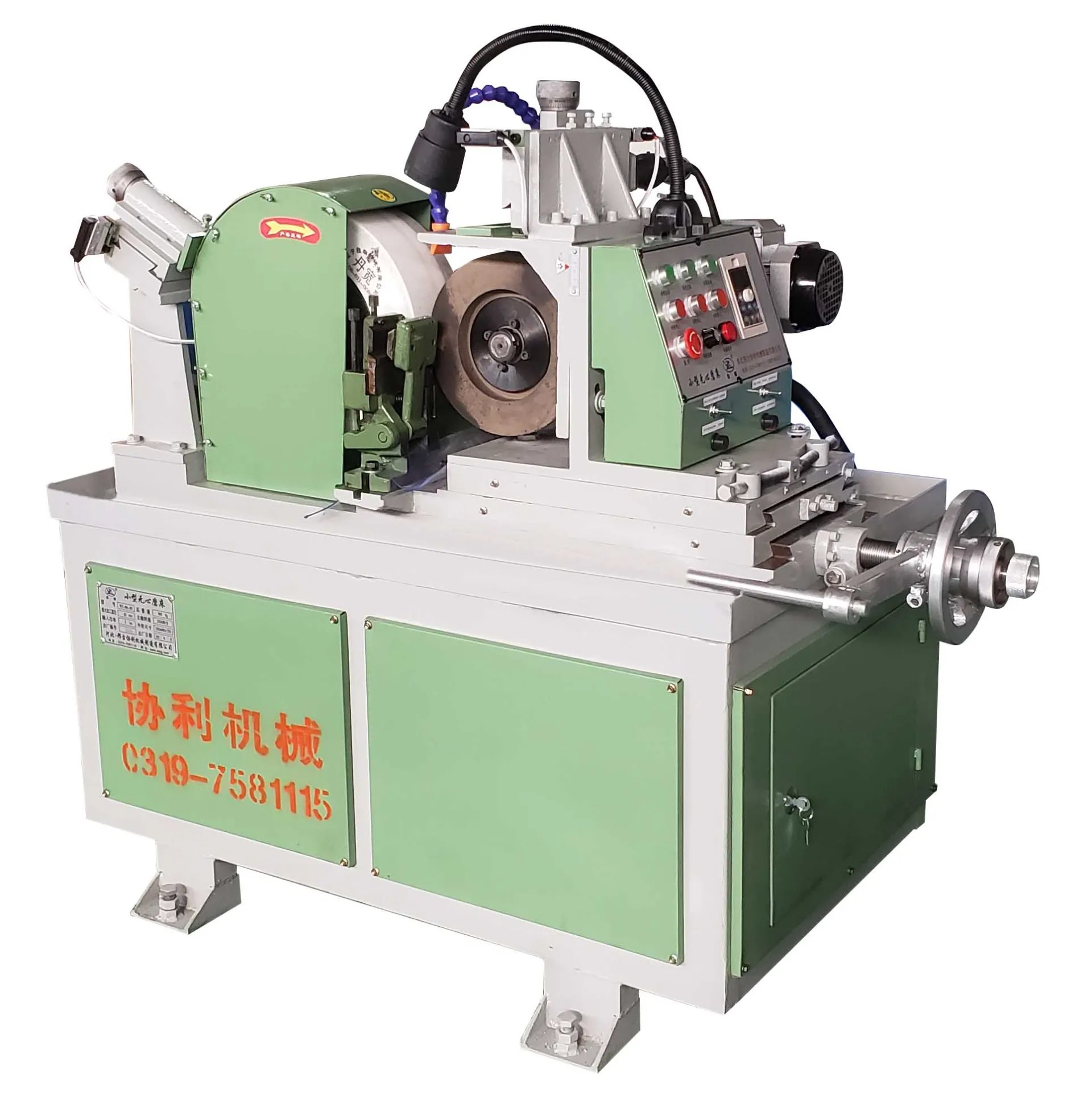

tube(pipe) grinding machine

Furthermore, real-world applications testify to the trustworthiness and reliability of tube grinding machines. In industries such as oil and gas, precision-ground tubing is vital to equipment that withstands harsh conditions. Such scenarios require equipment that bears the hallmark of robust engineering and unwavering performance, characteristics epitomized by these machines.

In addition, manufacturers of tube grinding machines have fortified their market position by demonstrating expertise through continuous innovation. The evolution of these machines is a testament to the industry's commitment to efficiency and precision, adopting cutting-edge technologies like IoT (Internet of Things) for predictive maintenance. This advancement ensures that any potential disruptions in the manufacturing process can be identified and addressed proactively, thus enhancing operational reliability.

Ultimately, acquiring a tube grinding machine is not merely about enhancing operational capacity but is also a strategic investment in the company’s future. Companies that leverage these machines experience enhanced product quality, improved operational efficiency, and sustainable growth. The strategic selection and integration of tube grinding machines into manufacturing processes represent a forward-thinking approach to business, underscoring the credentials of any enterprise that values quality and precision.

In summation, the unparalleled functionality, robust design, and innovative features of tube grinding machines make them an indispensable asset in modern manufacturing. Their application goes beyond simple tasks to forming the backbone of industries that prioritize precision, reliability, and efficiency. With the right expertise and operational knowledge, businesses can unlock the full potential of these machines, paving the way for future industrial advancements.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.