The Growing Market for Tube Buffing Machine Exporters

In recent years, the global demand for tube buffing machines has witnessed significant growth, driven by advancements in manufacturing processes and the rising need for high-quality surface finishing in various industries. Tube buffing machines are essential for achieving a polished, smooth finish on metal tubes used in sectors ranging from automotive to aerospace, and from construction to furniture manufacturing. This article explores the world of tube buffing machine exporters, highlighting their role in the international market, challenges they face, and future prospects.

Understanding Tube Buffing Machines

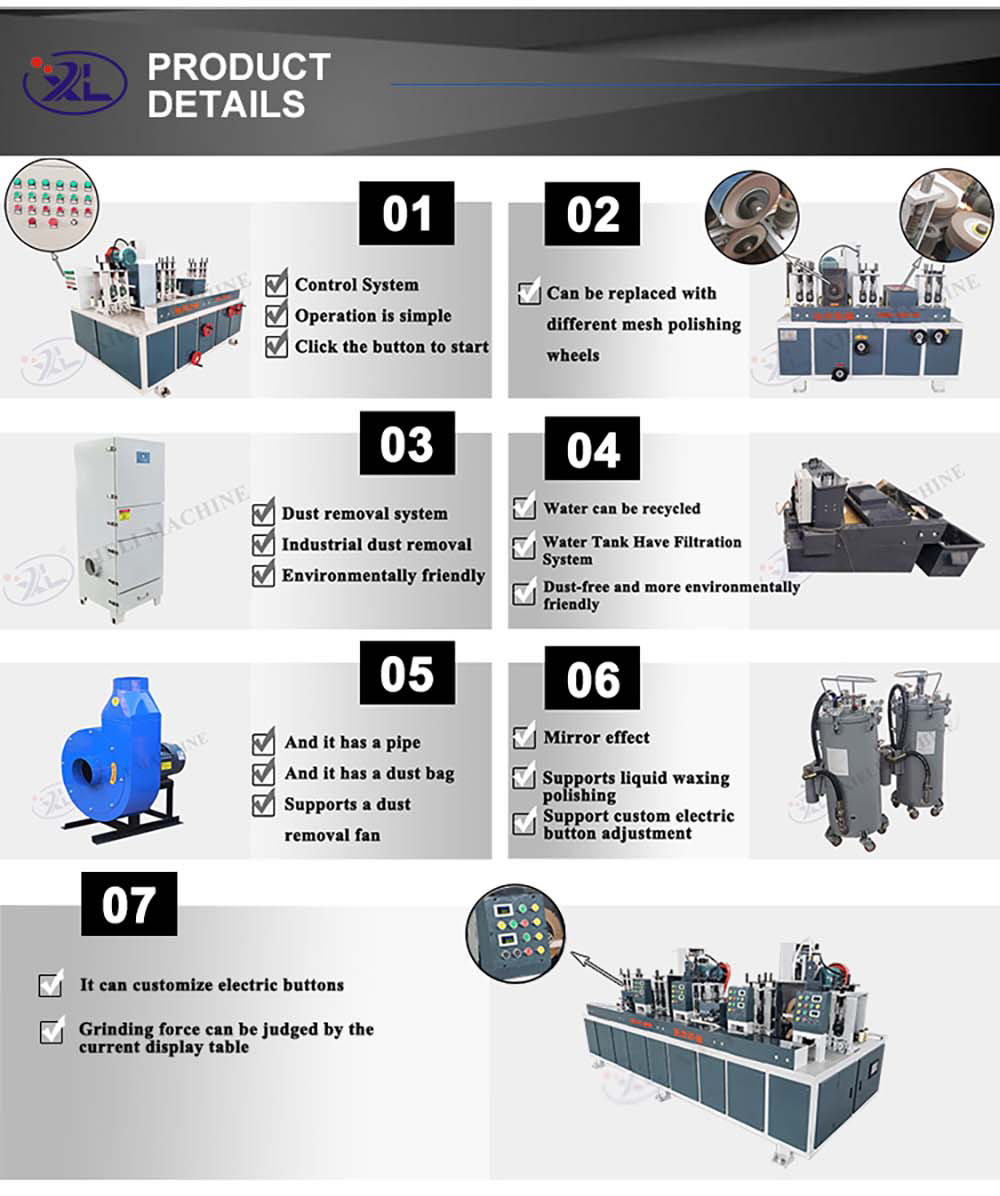

Tube buffing machines are specially designed equipment that helps in the surface finishing of tubes and pipes through buffing and polishing processes. These machines eliminate imperfections, enhance surface gloss, and improve corrosion resistance, making them crucial in ensuring that the finished products meet industry standards and customer expectations. The technology has evolved rapidly, with automated systems and CNC capabilities making operations more efficient and repeatable.

The Export Landscape

As industries continue to expand globally, the market for tube buffing machines is increasingly characterized by exports. Manufacturers in countries like China, Germany, Italy, and the United States are at the forefront of this market. These exporters benefit from advanced technology, a deep understanding of engineering principles, and a commitment to quality control which positions them favorably in the competitive landscape.

Exporters of tube buffing machines cater to a diverse clientele, including manufacturers in developing countries looking to improve their production capabilities, and established companies in developed markets seeking state-of-the-art equipment. The growth in international trade agreements has further facilitated the expansion of tube buffing machine exports by reducing tariffs and eliminating trade barriers.

Challenges Faced by Exporters

tube buffing machine exporters

Despite the potential for growth, tube buffing machine exporters face several challenges. One significant obstacle is the variability in regulations and standards across different countries. Exporters must ensure their machines comply with local safety and environmental standards, which can vary drastically from one region to another. This requires continuous investment in research and compliance measures, which can be costly.

Exchange rate fluctuations also pose a risk for exporters. As manufacturers price their machines competitively in local markets, any volatility in exchange rates can significantly impact profit margins. Additionally, the logistics of exporting machinery can be complex, involving shipping, customs clearance, and handling, which can all contribute to delays and increased costs.

The Future of Tube Buffing Machine Exports

Looking ahead, the future of tube buffing machine exporters appears promising. The demand for automation and advanced manufacturing technologies is on the rise, and businesses are increasingly recognizing the importance of investing in high-quality tube buffing systems to enhance productivity and product quality. Furthermore, the push for sustainability and energy efficiency in manufacturing practices is driving innovation in machine design, presenting opportunities for exporters to develop and promote eco-friendly solutions.

Emerging markets in Asia, Africa, and South America are also expected to play a crucial role in the expansion of the tube buffing machine export market. As industrialization progresses in these regions, the demand for modern manufacturing equipment will likely surge, providing exporters with new avenues for growth.

Conclusion

In conclusion, tube buffing machine exporters are positioned at a significant junction of opportunity and challenge. The evolving landscape of global manufacturing, coupled with the increasing demand for polished and well-finished products, indicates a bright future for this niche market. By navigating regulatory challenges, embracing innovation, and exploring new markets, tube buffing machine exporters can continue to thrive and contribute to the enhancement of manufacturing processes worldwide. As technology advances, so too will the capabilities of these machines, ensuring that industries are equipped with the best tools to meet consumer demands for quality and performance.