Tube Belt Polishing Machine Enhancing Metal Finishing Efficiency

The manufacturing and finishing processes in various industries, such as automotive, aerospace, and furniture, often require components to undergo surface treatment to improve their aesthetics, durability, and resistance to corrosion. Among the various tools employed in metal finishing, the tube belt polishing machine stands out as a vital piece of equipment that combines efficiency with quality results.

Understanding Tube Belt Polishing Machines

A tube belt polishing machine is specialized equipment designed specifically for polishing cylindrical metal components, including tubes and pipes. These machines utilize abrasive belts to remove surface imperfections, such as scratches, oxidation, and rust, thereby providing a smooth, reflective finish to metal surfaces. The versatility of tube belt polishing machines makes them useful in a wide range of materials including stainless steel, aluminum, copper, and brass.

Key Components and Features

Typically, a tube belt polishing machine consists of several key components that contribute to its functionality

1. Abrasive Belts These are vital for the polishing process. The choice of abrasive material and grit size affects the finish quality. Coarser grits are used for initial material removal, while finer grits create the final polish. 2. Drive System This includes motors and pulleys that control the movement of the abrasive belts. A robust drive system ensures that the belts maintain a consistent speed and pressure during operation.

3. Workpiece Holder This component secures the tubular workpieces in place, allowing for stable and even polishing. Adjustable holders accommodate various tube diameters.

4. Control Panel Modern machines often boast user-friendly control panels that allow operators to set parameters such as belt speed and pressure, optimizing the polishing process according to material type and desired finish.

5. Dust Collection System To maintain a clean working environment and enhance operator safety, many machines are equipped with dust extraction systems that remove debris generated during polishing.

Advantages of Using Tube Belt Polishing Machines

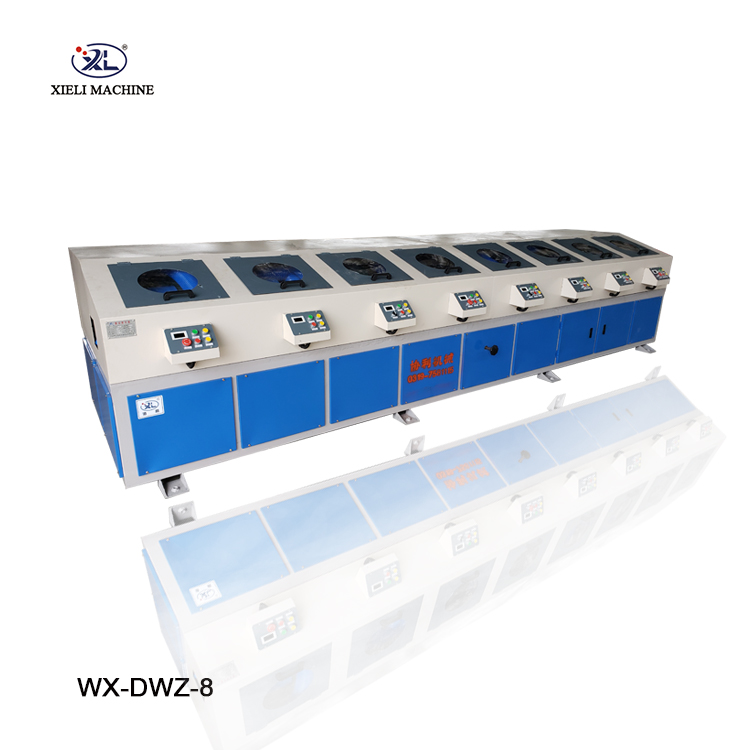

tube belt polishing machine

The advantages of employing tube belt polishing machines are numerous

1. Efficiency These machines significantly reduce the time and labor required for polishing metal surfaces compared to manual methods. By automating the process, manufacturers can increase productivity and throughput.

2. Consistency Achieving a uniform finish on all workpieces can be challenging with manual polishing. Tube belt polishing machines provide consistent results, ensuring that each piece meets quality standards.

3. Versatility Tube belt polishing machines can be adapted to polish various tube sizes and shapes, making them a flexible addition to any workshop or manufacturing facility.

4. Quality of Finish The ability to use different types of abrasive belts allows for tailored finishing processes that can achieve high gloss levels, satin finishes, or even bead-blasted effects depending on the application.

5. Reduction in Labor Costs By automating the polishing process, businesses can minimize their labor costs and redirect skilled workers to other critical tasks within the manufacturing process.

Applications Across Industries

Tube belt polishing machines are used across a broad range of industries. In the automotive sector, they are essential for finishing exhaust pipes and decorative trims. In aerospace, they help produce components that meet stringent quality and safety standards while ensuring weight efficiency. Additionally, the furniture industry relies on these machines to give high-end metal furniture pieces a polished and attractive finish.

Conclusion

In conclusion, the tube belt polishing machine is an indispensable tool in the realm of metal finishing. Its ability to enhance efficiency and significantly improve product quality makes it essential for various industries focused on surface treatment of metal components. As technology continues to evolve, we can expect further innovations in tube belt polishing systems, leading to even better performance and output. Investing in a tube belt polishing machine is not merely a purchase; it is a step towards achieving excellence in manufacturing processes.