Exploring the World of Tschudin Centerless Grinders Exporters and Their Impact

In the realm of precision manufacturing, centerless grinding is a critical process used to produce high-quality cylindrical components. Among the key players in this market is Tschudin, a renowned Swiss manufacturer known for its innovative centerless grinding machines. As globalization continues to shape the manufacturing landscape, Tschudin's centerless grinders have gained significant traction among exporters worldwide. This article delves into the features of Tschudin centerless grinders, the role of exporters, and the broader implications for the industry.

Features of Tschudin Centerless Grinders

Tschudin centerless grinders are designed with state-of-the-art technology to accommodate various manufacturing needs. They excel in producing parts with tight tolerances and exquisite surface finishes, making them a preferred choice for industries such as automotive, aerospace, and medical devices. One of the standout features of Tschudin machines is their ability to handle a wide range of diameters and lengths, making them versatile in different applications.

Additionally, Tschudin has pioneered several innovations to enhance productivity and efficiency. Their grinders often incorporate advanced software for control and monitoring, allowing manufacturers to optimize the grinding process and reduce downtime. The machines are also engineered to minimize vibration and thermal effects, which can adversely affect precision, thus ensuring consistently high-quality outputs.

Moreover, Tschudin's commitment to sustainability is evident in their design choices, aiming to minimize energy consumption and waste generation. This focus on eco-friendly manufacturing aligns with the increasing demand for sustainable practices across industries, offering an added appeal for potential buyers.

The Role of Exporters

Exporters play a pivotal role in expanding the reach of Tschudin centerless grinders to different international markets. These companies serve as intermediaries, connecting the Swiss manufacturer with potential clients worldwide. By leveraging their expertise in logistics, compliance, and market analysis, exporters help to navigate complex trade regulations and ensure that machinery meets local standards.

Furthermore, exporters often provide essential after-sales support, including installation, maintenance, and training. This assistance is crucial for companies unfamiliar with Tschudin's technology, ensuring that clients can operate the machinery effectively and achieve optimal results. The establishment of robust support networks enhances customer satisfaction and loyalty, further bolstering the brand's reputation in global markets.

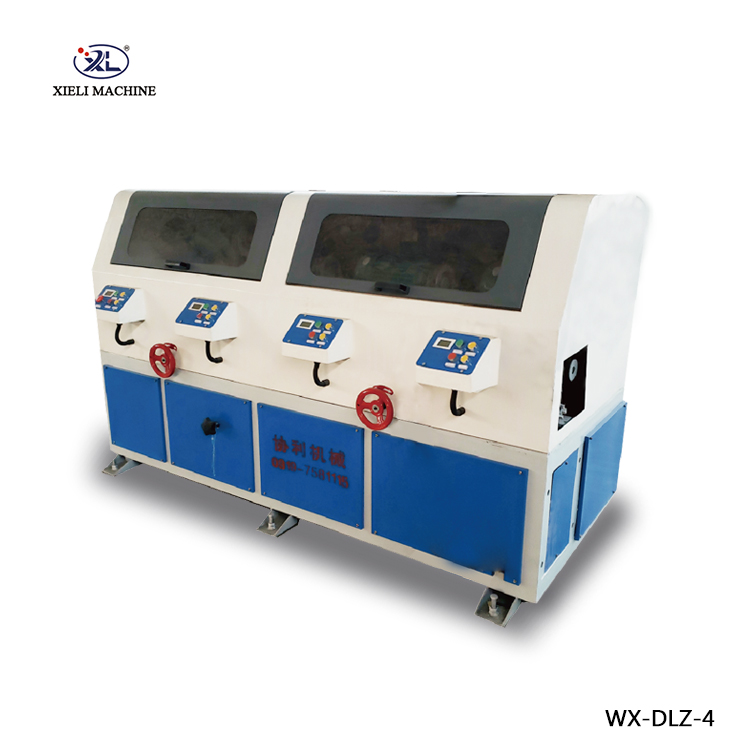

tschudin centerless grinder exporters

Market Trends and Opportunities

The demand for high-precision components is on the rise, driven by advancements in technology and the increasing complexity of products. Industries such as electric vehicles, renewable energy, and high-precision medical devices are experiencing rapid growth, creating a greater need for reliable manufacturing processes like centerless grinding.

As companies seek to enhance their production capabilities, the demand for Tschudin centerless grinders is likely to grow. Exporters are well-positioned to capitalize on this trend, as they can connect manufacturers with the right machines to meet their specific requirements. Collaboration between Tschudin and exporting partners can lead to the development of tailored solutions that address the unique challenges faced by different sectors.

Challenges and Considerations

Despite the promising outlook, there are challenges that exporters and manufacturers must contend with. Fluctuating global trade policies and tariffs can impact the import and export of machinery, potentially affecting pricing and availability. Moreover, as the market for centerless grinding machines becomes increasingly competitive, Tschudin and its exporters must continuously innovate and adapt to maintain their edge.

Additionally, the rapid pace of technological change means that manufacturers must stay ahead of emerging trends, such as automation and Industry 4.0 initiatives. Embracing these advancements will be crucial for exporters and manufacturers alike, ensuring they can meet evolving customer demands and drive further growth.

Conclusion

Tschudin centerless grinders exemplify precision engineering and innovation in the manufacturing sector. The role of exporters in connecting these machines with global markets cannot be overstated, as they facilitate the exchange of technology and expertise. As the demand for high-quality components continues to rise, the collaboration between Tschudin and its exporting partners will play a significant role in shaping the future of the centerless grinding industry. By navigating challenges and seizing opportunities, both manufacturers and exporters can drive sustained growth and contribute to the ongoing evolution of precision manufacturing.