Best Junker Centerless Grinder A Comprehensive Overview

When it comes to precision manufacturing and achieving optimal surface finishes, the role of high-quality grinding machines cannot be overstated. Among the various types of grinding machines, centerless grinders stand out for their efficiency and capacity to handle different workpieces. One brand that has made a significant mark in this industry is Junker, known for its innovative technology and reliability. This article delves into why the Junker centerless grinder is often considered the best choice for manufacturers looking for quality, durability, and cost-efficiency.

Understanding Centerless Grinding

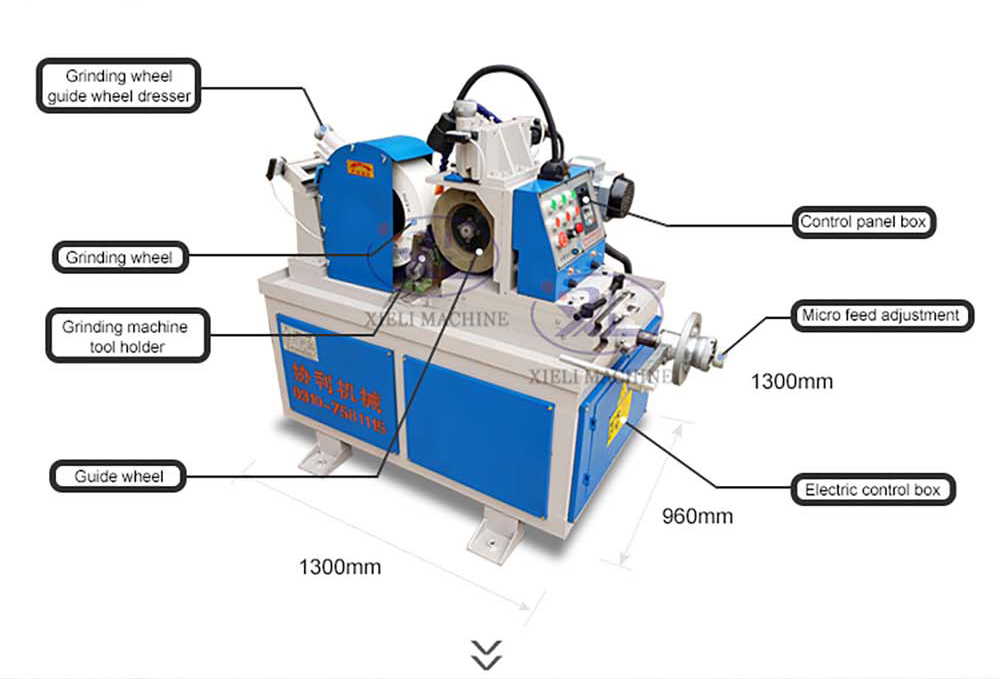

Before we dive into the specifics of Junker centerless grinders, it's essential to understand what centerless grinding is. Unlike traditional grinding methods, centerless grinding does not require a fixture to hold the workpiece. Instead, the workpiece is placed between two wheels a grinding wheel and a regulating wheel. This setup allows for continuous, precise grinding without the need for complex setup processes, making it suitable for high-volume production.

The Junker Advantage

Junker has been in the grinding machine industry for several decades, and their centerless grinders exemplify technological advancement and operational efficiency

. Here are several reasons why Junker centerless grinders are regarded as the best1. Precision and Accuracy One of the most significant advantages of Junker centerless grinders is their exceptional precision. These machines are designed to deliver extremely tight tolerances, ensuring that manufacturers can meet stringent specifications. This precision is critical in industries such as automotive, aerospace, and medical device manufacturing, where even the slightest deviation can lead to failures and increased costs.

best junker centerless grinder

2. Innovative Technology Junker continuously invests in research and development, leading to groundbreaking innovations that enhance the performance of their grinding machines. For instance, many models feature advanced CNC controls, allowing for real-time monitoring and adjustments. This automation significantly reduces the risk of human error and improves the overall production efficiency.

3. Versatility Junker centerless grinders are remarkably versatile, capable of grinding a wide range of materials, including hard metals and soft alloys. This adaptability makes them suitable for a variety of applications, from producing complex shapes to achieving fine surface finishes. Manufacturers can easily switch between different workpieces, maintaining productivity across diverse projects.

4. Robust Build Quality Built to last, Junker centerless grinders are constructed from high-quality materials, which result in machines that can withstand rigorous operations. Their robust design minimizes vibrations and ensures stable grinding processes, which further contributes to the accuracy of the finished product.

5. User-Friendly Interface The design of Junker centerless grinders takes user experience into account. Many models come with intuitive control panels that simplify operation and maintenance. This user-friendly approach allows operators to focus on productivity rather than troubleshooting technical issues.

6. Cost Efficiency While investing in quality machinery may seem daunting, Junker centerless grinders offer excellent value for money. Their durability and efficiency lead to lower operational costs over time. Additionally, the reduction in waste and increased production rates create significant savings for manufacturers.

Conclusion

In summary, Junker centerless grinders exemplify the pinnacle of modern grinding technology. Their precision, innovative features, and robust construction make them an ideal choice for manufacturers aiming to enhance their production capabilities. Whether you're looking to optimize workflow, improve quality control, or expand your operational capacity, opting for a Junker centerless grinder will undoubtedly prove to be a wise investment. As the manufacturing landscape continues to evolve, having the right equipment—like the Junker centerless grinder—will ensure that businesses remain competitive and capable of meeting the demands of their customers.