The Rise of SS Pipe Polishing Machine Companies Innovations in Metal Finishing

In the realm of metal processing, the importance of surface finishing cannot be overstated. Among the various techniques available, pipe polishing has gained significant attention, especially for stainless steel (SS) pipes. The growing demand for stainless steel products across industries has paved the way for a surge in SS pipe polishing machine companies. These companies play a vital role in enhancing the aesthetic and functional properties of stainless steel pipes, making them essential players in the manufacturing landscape.

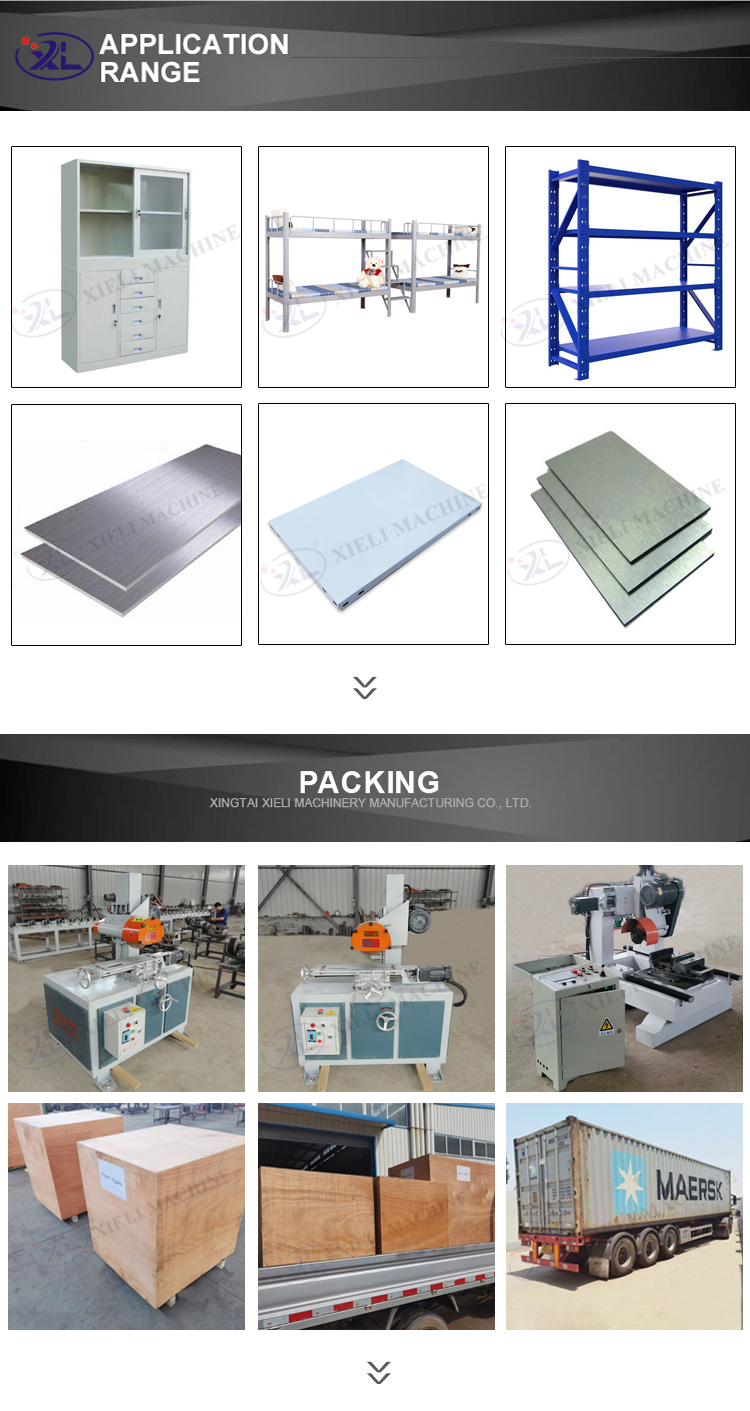

Stainless steel is renowned for its corrosion resistance, durability, and sleek appearance, making it a favored material in sectors such as construction, automotive, food processing, and pharmaceuticals. However, the raw finish of stainless steel pipes often falls short of the high standards required for many applications. This is where stainless steel pipe polishing comes into play, effectively improving the surface quality, mitigating imperfections, and enhancing corrosion resistance.

The Rise of SS Pipe Polishing Machine Companies Innovations in Metal Finishing

As the industries demand higher-quality products, SS pipe polishing machine companies have had to innovate continuously. The advancement of technology has seen the emergence of automated and semi-automated polishing systems designed to enhance productivity and consistency. These machines often feature programmable controls that allow operators to adjust parameters such as speed, pressure, and direction, ensuring repeatable results that meet stringent quality standards.

ss pipe polishing machine companies

Moreover, with sustainability becoming a focus across industries, many companies are integrating eco-friendly practices into their operations. This includes the use of biodegradable polishing compounds and implementing waste recovery systems to minimize environmental impact. Manufacturers are now looking beyond mere aesthetics; they wish to produce stainless steel pipes that also align with global sustainability goals.

In addition to employing advanced technology and sustainable practices, SS pipe polishing machine companies are also investing in customer service and support. Understanding that each client may have unique requirements, many companies offer customized polishing solutions tailored to specific industry needs. This not only enhances customer satisfaction but also solidifies long-term partnerships in a competitive market.

The growth of the SS pipe polishing machine market is further fueled by the globalization of manufacturing. As industries in developing countries ramp up their production capabilities, the demand for high-quality stainless steel components increases. This trend is not merely about the machines; it's also about the skills and expertise of the operators. Quality training programs are becoming essential, ensuring that personnel are well-equipped to handle advanced polishing technologies.

In conclusion, the emergence and evolution of SS pipe polishing machine companies signify a critical step forward in the metal finishing industry. With advanced machinery, sustainable practices, and customer-focused solutions, these companies are not only meeting the high demands of various sectors but also setting a benchmark for quality and innovation. As the industries continue to grow and evolve, the role of these specialized companies will only become more prominent, driving further advancements in surface finishing technology for stainless steel pipes. The journey of stainless steel pipe polishing is one of continuous improvement, reflecting the industry's commitment to excellence.