The Best Centerless Grinder with a Surface Grinder A Comprehensive Overview

In the realm of precision machining, the choice of grinding equipment plays a pivotal role in achieving superior surface finishes and dimensional accuracy. Among the various types of grinders, centerless grinders combined with surface grinders stand out for their efficiency and versatility. This article delves into the best centerless grinders with surface grinding capabilities, exploring their features, benefits, and applications.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinders, centerless grinders do not require a fixture for the workpiece, allowing for continuous operation and improved productivity. The workpiece is supported by a rotary blade and a regulating wheel, which holds it in place during the grinding operation. This process is ideal for cylindrical parts, often used in automotive, aerospace, and various industrial applications.

Benefits of Combining Centerless and Surface Grinding

The integration of surface grinding capabilities into a centerless grinder opens up a world of possibilities for manufacturers. This combination offers several advantages

1. Increased Efficiency Operating both grinding processes in a single machine reduces setup time and increases throughput. Manufacturers can process parts more rapidly while maintaining high levels of precision.

2. Superior Surface Finish The combination of centerless and surface grinding allows for the achievement of exceptional surface finishes. The surface grinder refines the workpiece, eliminating any residual imperfections left by the initial grinding process.

3. Space-Saving Design Utilizing a single machine for both processes saves valuable floor space in a manufacturing facility. This compact design is particularly advantageous for small shops or facilities with limited space.

best centerless grinder with a surface grinder

4. Versatility Machines that offer both centerless and surface grinding capabilities can be adapted to handle a wide range of materials and geometries. This versatility allows manufacturers to cater to various needs, from high-volume production to specialized tasks.

Features to Look For

When searching for the best centerless grinder with a surface grinder, certain features should be prioritized

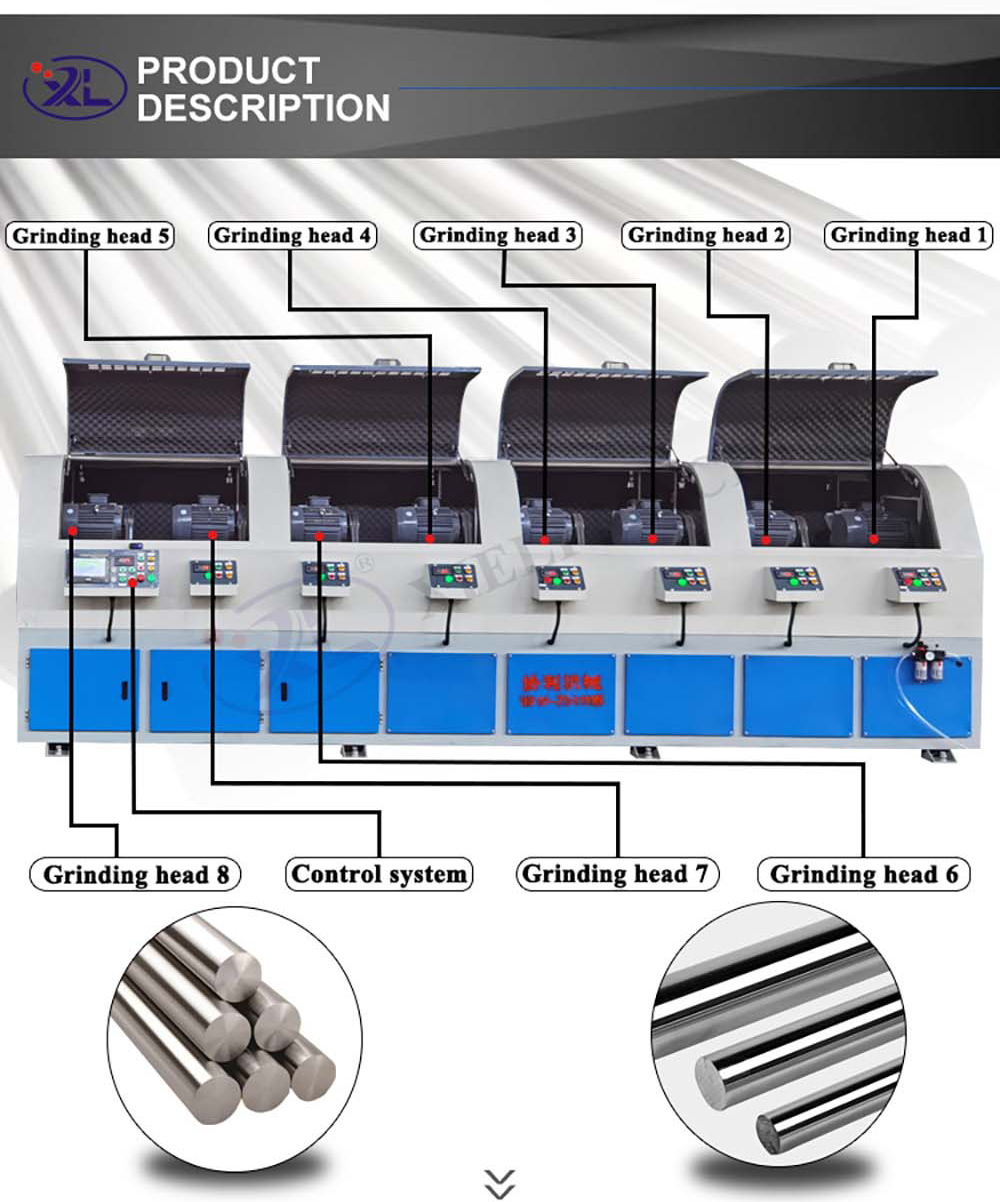

- Precision Control Systems Look for machines equipped with advanced control systems that allow for precise adjustments to grinding speed, depth, and angle. This enables operators to achieve the desired tolerances consistently.

- Robust Construction A grinder made from high-quality materials will ensure durability and longevity. Consider machines that have a rigid base and high-strength components to withstand the rigors of heavy use.

- User-Friendly Interface An intuitive interface simplifies operation and reduces the learning curve for new operators. Features such as digital displays and programmable settings are invaluable for efficient workflows.

- Customizability The best machines offer options for customization, allowing businesses to configure the grinder to meet specific production requirements.

Conclusion

Investing in the best centerless grinder with a surface grinder capabilities significantly enhances a manufacturing operation's efficiency, precision, and quality. With improved production times and superior surface finishes, this integrated grinding solution is an essential asset for modern machining environments. By prioritizing features such as precision control, robust construction, user-friendliness, and customizability, manufacturers can select the ideal machine that meets their specific demands and sets them on the path to success in their industry.