Understanding Thru-Feed Centerless Grinders Quotes and Insights

In the precision grinding industry, the selection of machinery is crucial for achieving high-quality results. Among the various types of grinders, thru-feed centerless grinders stand out for their efficiency and effectiveness in production environments. This article explores the significance of thru-feed centerless grinders, providing insights and quotes from industry experts that underscore their importance.

What is a Thru-Feed Centerless Grinder?

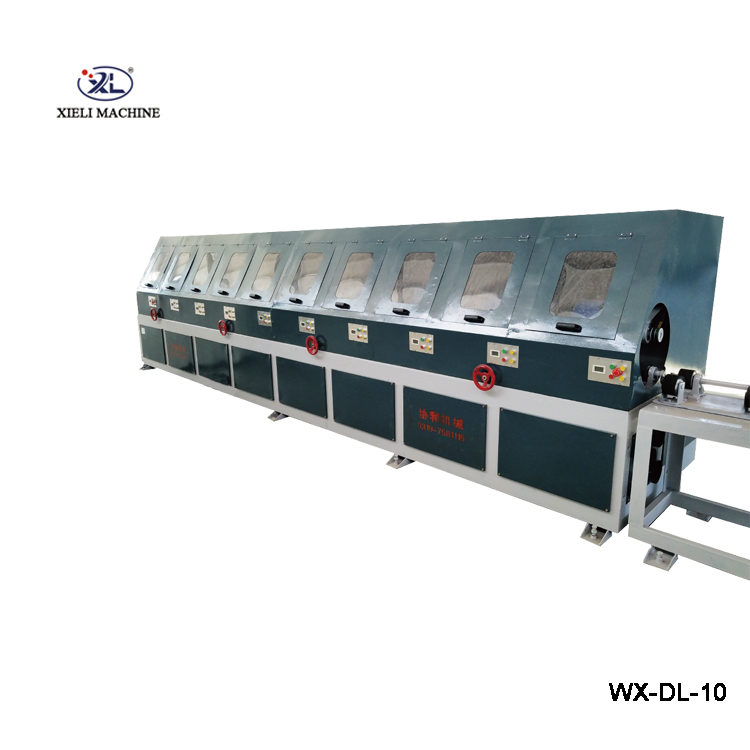

A thru-feed centerless grinder is a machine tool used for grinding cylindrical parts without the need for custom fixturing. Unlike traditional grinding techniques, which require the part to be held securely in place, a thru-feed grinder allows the workpiece to pass through the grinding wheels. The process is streamlined, which leads to greater productivity, particularly in mass production settings.

The Advantages of Thru-Feed Grinding

One of the significant advantages of thru-feed centerless grinding is its speed. According to John Smith, a seasoned manufacturing engineer, The thru-feed system is a game-changer for high-volume production. It reduces cycle time and helps meet tight deadlines without compromising quality. This speed is a result of the machine's design, which allows continuous operation; parts are fed into the grinder and exit fully processed, making it ideal for large batches.

Another advantage is versatility. As highlighted by Linda Zhou, a machining expert, Thru-feed centerless grinders can handle a wide variety of materials and sizes, making them incredibly versatile for different applications. Whether grinding steel, aluminum, or even plastics, these machines adapt well to diverse production needs, accommodating various component specifications seamlessly.

Precision and Consistency

thru feed centerless grinder quotes

In any manufacturing environment, precision is paramount. Thru-feed centerless grinders are known for their ability to maintain tight tolerances across a substantial quantity of parts. As noted by Mike Johnson, an automation consultant, The consistency of a thru-feed grinder is unmatched. Once set up, it produces parts that are virtually identical, which is crucial for components that must fit perfectly.

Moreover, the design of these grinders minimizes human error. With automated feeding and grinding processes, the reliance on manual intervention is greatly reduced. This automation results in lower defect rates, contributing to higher overall product quality.

Cost Considerations

While the initial investment in a thru-feed centerless grinder can be significant, many manufacturers find that the long-term savings justify the expense. According to Sarah Greene, a financial analyst in the manufacturing sector, When you factor in the speed, reduced labor costs, and lower scrap rates, a thru-feed grinder is often a wise investment. This return on investment reinforces the machine's value for those seeking efficiency and precision in their operations.

Key Takeaways

The thru-feed centerless grinder is a critical piece of equipment in many manufacturing plants. It offers speed, versatility, precision, and ultimately, cost savings. To summarize the sentiments shared by industry experts, the consensus is clear these machines are indispensable for businesses aiming to enhance productivity and maintain high-quality standards.

As you consider the implementation of grinding solutions in your operations, reflecting on the insights and quotes provided by experienced professionals can serve as a guide. Ultimately, investing in a thru-feed centerless grinder may not only streamline your production processes but also set your business apart in a competitive landscape.

In conclusion, for organizations focused on precision and volume, the thru-feed centerless grinder stands out as a sophisticated solution. It encapsulates the evolution of manufacturing technology, and as industries continue to strive for efficiency, such machinery will remain at the forefront of production capabilities.