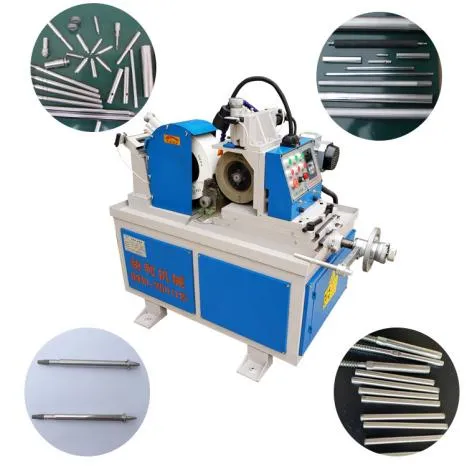

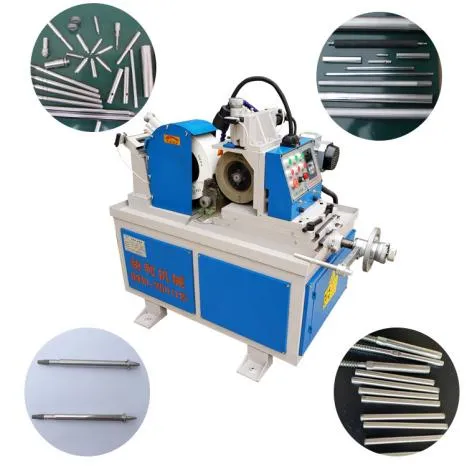

A thru feed centerless grinder, a pivotal component in the manufacturing industry, is gaining notable traction for its efficiency in high-volume production environments. For businesses investing in this technology, the decision should be informed by a blend of genuine experiences, specialized insight, authoritative recommendations, and a foundation of trustworthiness to ensure the optimization of production lines and the achievement of precision in parts machining.

From firsthand experiences shared by industry professionals, the transformation in operational flow after integrating a thru feed centerless grinder is remarkable. These machines stand out due to their ability to process parts continuously without the need for setup between pieces, making them an ideal choice for facilities focusing on parts that require repeated and uniform grinding operations. Users report significant reductions in cycle times, translating into accelerated production rates and cost-efficiency — indispensable for companies aiming for lean manufacturing methodologies.

Delving deeper into expertise, the design and functionality of thru feed centerless grinders are engineered for optimal performance under high-volume demands. Unlike other grinding methods, centerless grinding does not utilize a spindle, allowing for a high degree of flexibility and the capability to grind parts with varying lengths and short cycle times. The lack of need for a feed mechanism for each individual part underlines the machine’s expertise in addressing long production runs, while ensuring uniformity and precision. Consulting with seasoned manufacturers, such as those providing innovative grinder solutions, is critical for understanding the breadth of applications these machines cover, from automotive to aerospace and beyond.

thru feed centerless grinder factory

For businesses seeking authoritativeness, it's essential to choose a thru feed centerless grinder supplier with a proven track record and industry standing. A reputable factory should provide certifications verifying compliance with industry standards, detailed specifications of the grinder's capabilities, and endorsements from other organizations that have successfully utilized these machines. These elements not only affirm the machine's reliability but also demonstrate a commitment to quality and performance.

In terms of trustworthiness, potential buyers must consider the support and service structure surrounding the grinder. This includes the availability of warranty options, access to replacement parts, and continued customer support. A trustworthy manufacturer will offer extensive after-sales support, ensuring that the machine operates at peak efficiency and that any technical complications are promptly addressed. Transparency in communication and transactions further builds buyer confidence.

To conclude, selecting the right thru feed centerless grinder requires an understanding of operational benefits, backed by industry expertise and authoritative guidance. Emphasizing real-world experiences, professional counsel, authoritative credibility, and a trustworthy relationship with the supplier ensures the investment enhances production capabilities effectively and sustainably. As businesses navigate an increasingly competitive landscape, embracing this advanced grinding technology becomes pivotal in maintaining a leading edge in manufacturing excellence.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.