The Role of Throughfeed Centerless Grinders in Modern Manufacturing

In the realm of precision manufacturing, throughfeed centerless grinders have emerged as vital tools for efficiently shaping and finishing cylindrical parts. These machines are known for their ability to grind workpieces without the need for additional fixtures, streamlining the production process and enhancing overall efficiency. With the globalization of manufacturing, the demand for throughfeed centerless grinders has surged, paving the way for many exporters to meet this growing need in various markets around the world.

Understanding Throughfeed Centerless Grinding

Throughfeed centerless grinding is a unique machining process that allows for high-volume metalworking. Unlike traditional grinding methods, which often require the part to be held in place, the throughfeed method enables the workpiece to move continuously between two grinding wheels. One wheel serves as the grinding wheel, while the other serves as the regulating wheel, controlling the speed and feed rate of the workpiece.

This process is particularly advantageous for manufacturing operations focused on producing long, cylindrical components, such as shafts, pins, and rods. The efficiency of throughfeed centerless grinders makes them ideal for mass production scenarios, where speed and precision are paramount.

Key Advantages of Throughfeed Centerless Grinders

The benefits of using throughfeed centerless grinders are numerous

1. High Efficiency By continuously feeding workpieces through the grinding zone, manufacturers can process large quantities of parts in a short amount of time. This efficiency helps in reducing production costs and improving throughput.

2. Consistent Quality These machines maintain tight tolerances and deliver consistent surface finishes across all parts. The elimination of fixturing not only speeds up the process but also reduces the chances of human error, ensuring uniformity in production.

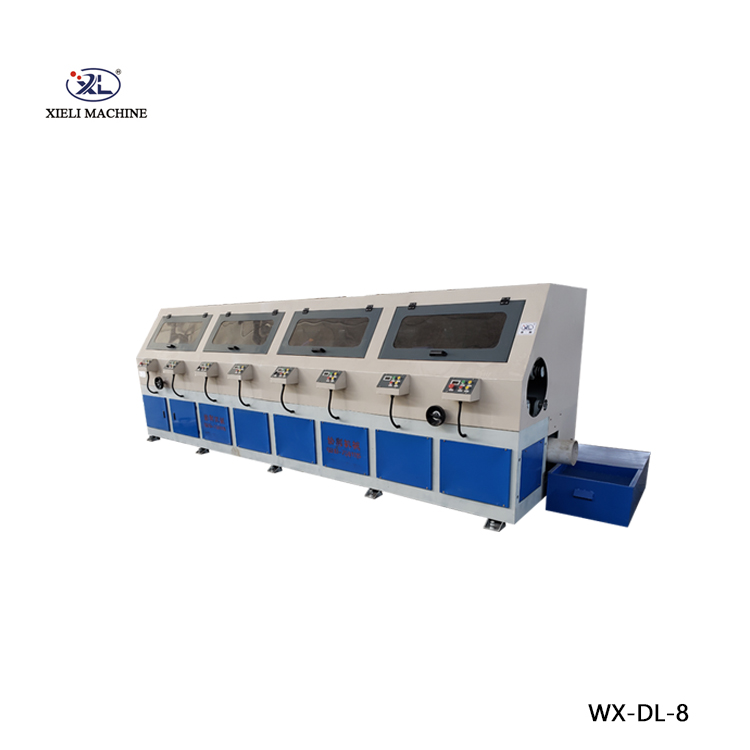

throughfeed centerless grinder exporters

3. Versatility Throughfeed centerless grinders can accommodate a variety of materials, including metals, plastics, and composites. This adaptability allows manufacturers to use these grinders across different industries, including automotive, aerospace, and medical device manufacturing.

4. Low Operational Costs Although the initial investment may be significant, the operational costs associated with throughfeed centerless grinding are relatively low. The machines require less manual intervention and are designed for durability, translating into lower maintenance and labor costs over time.

The Export Market for Throughfeed Centerless Grinders

As industries throughout the world embrace automation and advanced manufacturing techniques, the demand for throughfeed centerless grinders has increased significantly. Exporters of these machines play a crucial role in supplying various sectors, ensuring that manufacturers have access to the latest technology to meet their production goals.

Markets in North America, Europe, and Asia have shown particular interest in acquiring throughfeed centerless grinders, driving innovation and competition among exporters. These companies not only provide machinery but also offer comprehensive support, including installation, training, and maintenance services to ensure that their clients maximize the use of their equipment.

Additionally, as sustainability becomes a focal point for many manufacturers, exporters are also responding with machines that adhere to green manufacturing practices. By enhancing energy efficiency and minimizing waste, throughfeed centerless grinders contribute to more sustainable production processes.

Conclusion

Throughfeed centerless grinders represent an essential component of modern manufacturing. With their ability to deliver high efficiency, consistent quality, and versatility, they are indispensable for industries requiring precision machining of cylindrical parts. As global demand for these machines continues to grow, exporters play a pivotal role in facilitating advancements in manufacturing technology across various sectors.

The future of throughfeed centerless grinding looks promising, with ongoing innovations aimed at improving performance, efficiency, and sustainability. As manufacturers seek to optimize their production processes, throughfeed centerless grinders will undoubtedly remain at the forefront of the industry's machinery landscape.