Throughfeed Centerless Grinder Revolutionizing Precision Grinding

In the manufacturing world, precision machining is vital to maintaining competitive advantage, particularly in industries like automotive, aerospace, and medical devices. One of the most effective solutions for achieving high precision in the grinding process is the throughfeed centerless grinder. This innovative machine offers a seamless and highly efficient method for grinding cylindrical workpieces, allowing for increased productivity without compromising quality.

The throughfeed centerless grinding process is distinctive in its design and functionality. Unlike traditional grinding methods, which often require complex setups and fixtures, the throughfeed centerless grinder employs a unique arrangement. In this method, the workpiece is fed through the machine between two main wheels the grinding wheel and the regulating wheel. The grinding wheel, which is typically larger and rotates at a higher speed, removes material from the workpiece as it passes through, while the regulating wheel, positioned at a lower rotation speed, controls the feed rate and provides support. This system allows for continuous operation, making it ideal for mass production of cylindrical components.

One of the key advantages of a throughfeed centerless grinder is its ability to handle various sizes and shapes of workpieces without the need for multiple setups. This versatility is particularly beneficial for manufacturers who need to produce large quantities of parts with consistent precision. Moreover, the continuous nature of the process minimizes downtime, allowing for higher throughput compared to traditional grinding methods.

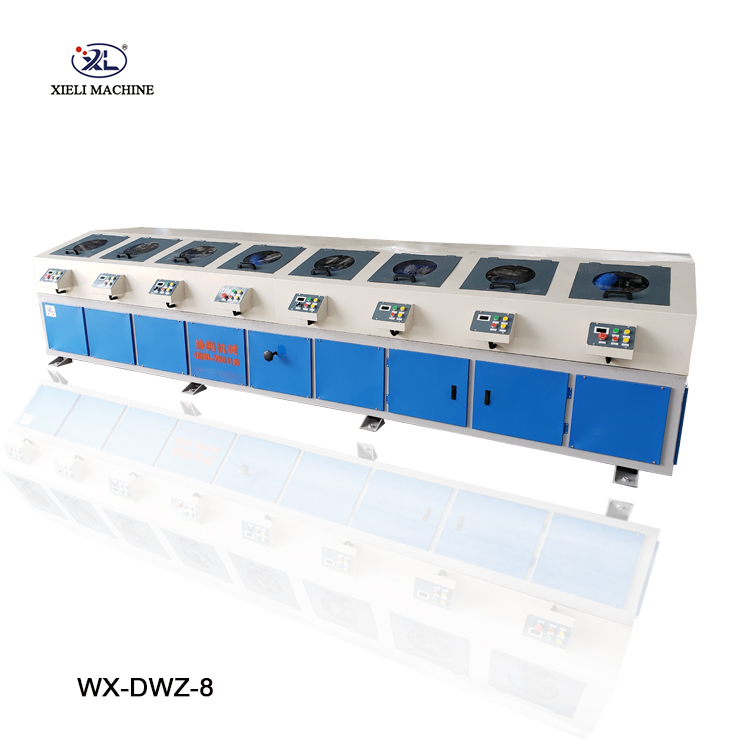

throughfeed centerless grinder

Additionally, throughfeed centerless grinders excel in producing tight tolerances and superior surface finishes. The controlled operation ensures that each part receives uniform grinding, resulting in high quality and minimal variation across the production run. This is crucial in industries where precision is paramount, such as in the production of bearing components or fuel injectors.

However, the effective use of a throughfeed centerless grinder does require careful consideration of factors such as part design, material, and grinding wheel specifications. Operators must also be skilled in setting up the machine properly to ensure optimal performance. Regular maintenance and monitoring of the grinding wheel and regulating wheel are essential to maintain the precision and efficiency of the grinding process.

In conclusion, the throughfeed centerless grinder stands out as a powerful tool in the realm of precision manufacturing. Its ability to handle mass production with exceptional accuracy and efficiency makes it an invaluable asset for industries that demand high-quality output. As technologies continue to evolve, the role of centerless grinding in modern manufacturing is likely to expand, driving innovation and productivity across various sectors.