Understanding the Importance of Table Top Centerless Grinder Service

In the world of precision machining, centerless grinders play a crucial role in enhancing productivity and achieving exact measurements with utmost efficiency. A specialized subset of these machines, the table top centerless grinder, has gained popularity due to its compact design and versatility. However, like any sophisticated machinery, regular maintenance and service are essential for optimal performance.

The Basics of Table Top Centerless Grinders

Table top centerless grinders are designed for small to medium-scale operations, providing an efficient solution for grinding different types of materials. These machines eliminate the need for centers, allowing for continuous production of cylindrical workpieces. The material is held between two grinding wheels that are positioned in such a way as to enable the workpiece to be fed through the machine without the requirement for additional fixtures.

Their compact size makes them ideal for workshops with limited space, while their versatility allows them to handle a variety of tasks—ranging from simple grinding to more complex finishing operations. These machines are primarily used in industries such as automotive, aerospace, and manufacturing, where precision and accuracy matter.

The Significance of Regular Service

Regular service and maintenance of table top centerless grinders are essential for several reasons

1. Maintaining Precision Any degradation in the grinding process can lead to variances in product quality. Routine checks ensure that the grinder operates within its specified parameters, offering consistent results.

2. Extending Machine Life Just like any machinery, wear and tear can significantly affect performance. Regular servicing helps identify potential issues before they lead to significant breakdowns, thereby extending the lifespan of the equipment.

3. Reducing Downtime Unscheduled machine failures can lead to costly delays in production. By ensuring regular maintenance checks, companies can dramatically reduce the risk of unexpected downtime.

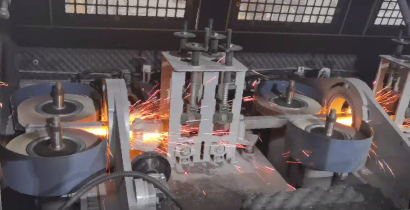

table top centerless grinder service

4. Cost Efficiency Investing in regular service can save money in the long run. It is often more cost-effective to maintain equipment than replace it. Moreover, well-maintained machines can operate more efficiently, saving on energy costs.

Key Aspects of Centerless Grinder Service

When it comes to servicing a table top centerless grinder, several key aspects should be considered

- Inspection of Grinding Wheels Over time, grinding wheels can wear down and become uneven. Regular checks and replacements are necessary to maintain efficient grinding operations.

- Alignment of Components The perfect alignment of the grinding and regulating wheels is crucial for achieving the desired surface finish. Misalignment can lead to poor results and increased wear.

- Lubrication Proper lubrication of moving parts minimizes friction and prevents overheating. Regular maintenance should include checking and replenishing lubricants.

- Calibration and Setup As products are manufactured in batches, precise calibration is vital. Regular servicing ensures that machines are set up correctly for new tasks and that specifications are met.

Conclusion

In conclusion, table top centerless grinders are indispensable tools in various industries that demand high precision and efficiency. Regular service and maintenance are crucial to maximizing their performance, ensuring quality output, and extending their operational lifespan. By investing in proper servicing practices, companies can enhance productivity and achieve significant cost savings over time. Understanding the importance of these machines and committing to their care will help businesses remain competitive in an ever-evolving market.