Table Top Centerless Grinder Manufacturers An Overview

In the world of precision machining, the importance of grinding technology cannot be overstated. Centerless grinding, in particular, has become an essential process in various industries, including automotive, aerospace, and manufacturing. Among the many options available in the market, table top centerless grinders have gained popularity for their compact design, efficiency, and ease of use. This article delves into the significance of table top centerless grinder manufacturers and the impact they have on modern manufacturing processes.

Understanding Table Top Centerless Grinders

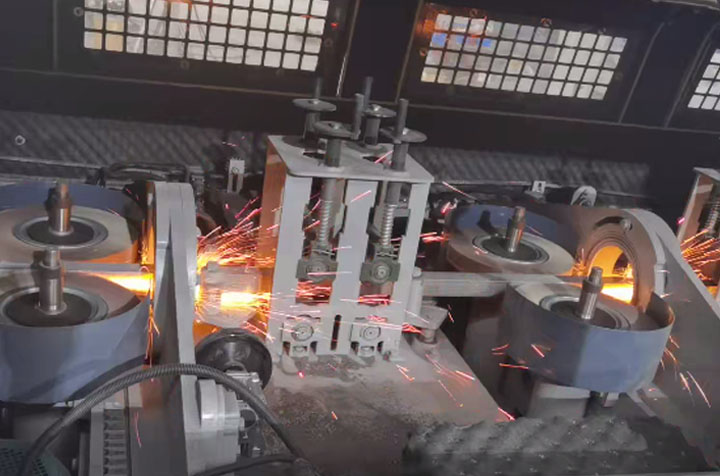

Table top centerless grinders are compact machines designed for precision grinding of cylindrical and rod-like components. Unlike traditional grinding machines, which require complex setups, centerless grinders operate without the need for a supporting fixture. This allows for quicker setups, higher throughput, and the capability to handle small parts with intricate geometries. Their design enables workpieces to be fed through the machine without the need for a chuck or tailstock, making them ideal for high-volume production.

Advantages of Table Top Centerless Grinders

1. Space Efficiency The key characteristic of table top grinders is their compact size. They are perfect for small workshops or facilities with limited space. Manufacturers frequently design their products with portability in mind, enabling easy relocation as needed.

2. Ease of Operation Table top grinders are user-friendly, making them accessible to operators with varying skill levels. Many modern machines are equipped with intuitive controls and automated features that enhance efficiency and reduce the learning curve.

3. Versatile Applications These grinders are capable of handling diverse materials, including metals, plastics, and composites, making them suitable for a wide range of applications. They are commonly used to grind parts for automotive engines, medical devices, and hardware components.

4. Enhanced Productivity The continuous feeding mechanism in centerless grinding machines allows for high-speed operations, significantly improving productivity. Manufacturers can produce up to thousands of parts in a single shift, leading to reduced labor costs and increased output.

table top centerless grinder manufacturers

Leading Table Top Centerless Grinder Manufacturers

With the growing demand for compact grinding solutions, several manufacturers have emerged as leaders in the field of table top centerless grinders. Some of the key players include

1. Glebar Company Known for their innovative grinding solutions, Glebar has developed a range of table top centerless grinders specifically designed for various industries. Their machines feature advanced automation and precision engineering, ensuring high-quality results.

2. Micron USA Specializing in high-precision grinding technologies, Micron USA offers a range of small-footprint centerless grinders. Their equipment is recognized for its durability and reliability, making it a popular choice among manufacturers.

3. Palmary Machinery Offering an extensive lineup of grinding machines, Palmary Machinery provides table top options tailored to specific needs. Their dedication to quality and innovation has earned them a strong reputation in the industry.

4. Koyo Machinery Koyo is renowned for its advanced grinding systems, including compact models that cater to the growing market for table top centerless grinders. Their solutions are designed for precision and efficiency, making them a top choice for precision engineering applications.

Conclusion

Table top centerless grinders have revolutionized the grinding process, providing manufacturers with a versatile and efficient solution for their precision machining needs. The advantages of compact size, ease of operation, and high productivity make them invaluable in modern manufacturing. As industries continue to seek ways to enhance their operations and improve quality, the role of table top centerless grinder manufacturers is becoming increasingly significant.

By utilizing these advanced grinding machines, companies can meet the demands of their customers while maintaining competitive advantages in the market. The expertise and innovation provided by leading manufacturers will undoubtedly shape the future of precision grinding, making table top centerless grinders an essential component of the manufacturing landscape.