The Rise of Table Top Centerless Grinders Revolutionizing Precision Engineering

In today’s fast-paced manufacturing landscape, precision engineering plays a pivotal role in ensuring the success of various industries. Among the tools that have gained significant traction in recent years, the table top centerless grinder stands out as an essential machine for achieving high levels of accuracy and efficiency in production processes. This article explores the importance of table top centerless grinders, their unique features, and the leading companies driving innovations in this field.

The Importance of Centerless Grinding

Centerless grinding is a manufacturing process that allows for the grinding of cylindrical parts without the necessity for a fixture to hold the workpiece in place. Instead, the workpiece is supported by a blade and is fed between the grinding wheel and the regulating wheel. This method is particularly advantageous because it enables high-volume output while maintaining tight tolerances. By eliminating the need for a traditional mounting system, centerless grinding enhances accessibility and reduces setup times.

Table top centerless grinders, in particular, have made this process more accessible to smaller shops and manufacturers that may not have the space or budget for larger units. These compact machines deliver precision grinding capabilities without sacrificing performance. As a result, they are increasingly used in various sectors, including automotive, aerospace, and medical device manufacturing.

Unique Features of Table Top Centerless Grinders

One of the most appealing aspects of table top centerless grinders is their design. Unlike their larger counterparts, these machines are compact and portable, making them ideal for small-batch production and workspaces with limited floor area. Many models offer adjustable settings, allowing operators to fine-tune parameters such as grinding speed and feed rate to suit specific applications.

Additionally, modern table top centerless grinders are equipped with advanced technology that enhances precision. CNC (Computer Numerical Control) capabilities ensure that the grinding process is consistent and repeatable. Operators can program complex grinding cycles, reducing the potential for human error and increasing overall productivity.

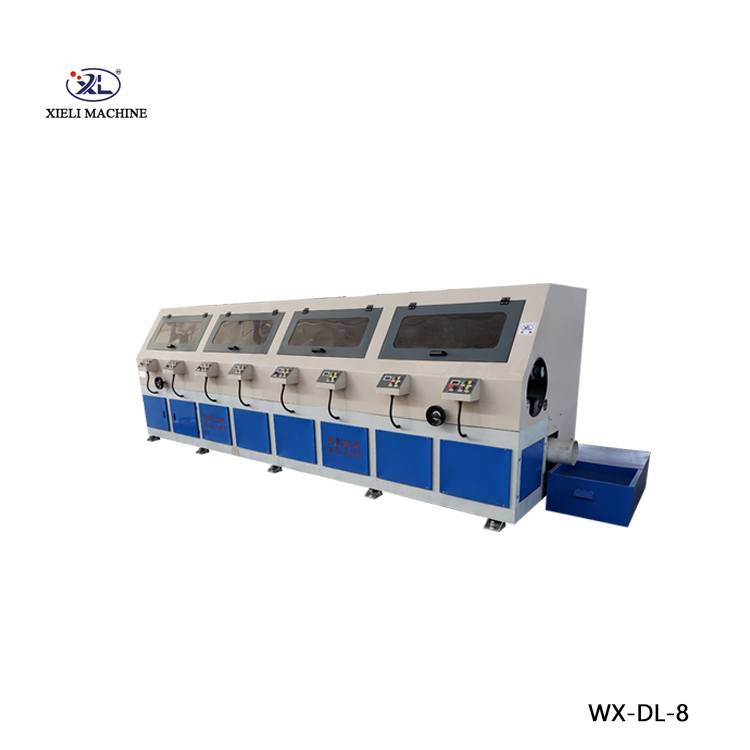

table top centerless grinder company

The ease of maintenance is another notable feature. Many manufacturers design their table top grinders with user-friendly components that allow for quick adjustments and routine maintenance tasks. This characteristic not only extends the lifespan of the machine but also minimizes downtime in production.

Leading Companies in Table Top Centerless Grinding

Several companies have emerged as leaders in the production of table top centerless grinders. These manufacturers are committed to innovation, quality, and customer satisfaction. Among them, companies like Micron, Royal Master Grinders, and Cincinnati Machines have earned reputations for their advanced engineering and reliability in the field.

Micron, for instance, focuses on high-precision grinding solutions, catering to industries that demand exacting tolerances. Their table top centerless grinders are designed to handle small to medium-sized workpieces, providing consistent performance suitable for any production line.

Royal Master Grinders is another key player, renowned for its agile designs and adaptability in creating customized solutions. Their machines are particularly well-regarded in the medical device sector, where precision and compliance with strict regulations are crucial.

Cincinnati Machines, with a history dating back to the late 19th century, continues to innovate in the field of grinding technology. Their table top grinders combine heritage craftsmanship with modern advancements, ensuring their machines meet the evolving needs of today’s manufacturers.

Conclusion

Table top centerless grinders represent a significant advancement in precision engineering, offering compact, efficient, and high-quality machining solutions. As industries continue to push for greater accuracy and efficiency, the demand for these machines is likely to grow. With leading companies driving innovation, the future of table top centerless grinding looks promising. The combination of advanced technology, user-friendly design, and a commitment to precision ensures that these machines will remain at the forefront of the manufacturing landscape for years to come.