The Evolution and Importance of Table Top Centerless Grinders

In the world of precision machining and grinding, the need for efficiency and accuracy remains paramount. Among the various types of grinding machines, table top centerless grinders have emerged as pivotal tools in both small workshops and large manufacturing plants. These compact yet powerful machines are designed to provide a unique grinding solution, offering distinct advantages over traditional grinding methods.

Understanding Centerless Grinding

Centerless grinding is a machining process that does not require the workpiece to be mounted between centers. Instead, it involves the use of two wheels the grinding wheel and the regulating wheel. The workpiece is held in place by the forces that result from these rotating wheels, allowing for efficient and continuous grinding. This process is particularly advantageous for cylindrical or round components, making it ideal for a variety of applications, from automotive parts to small precision instruments.

The Design of Table Top Centerless Grinders

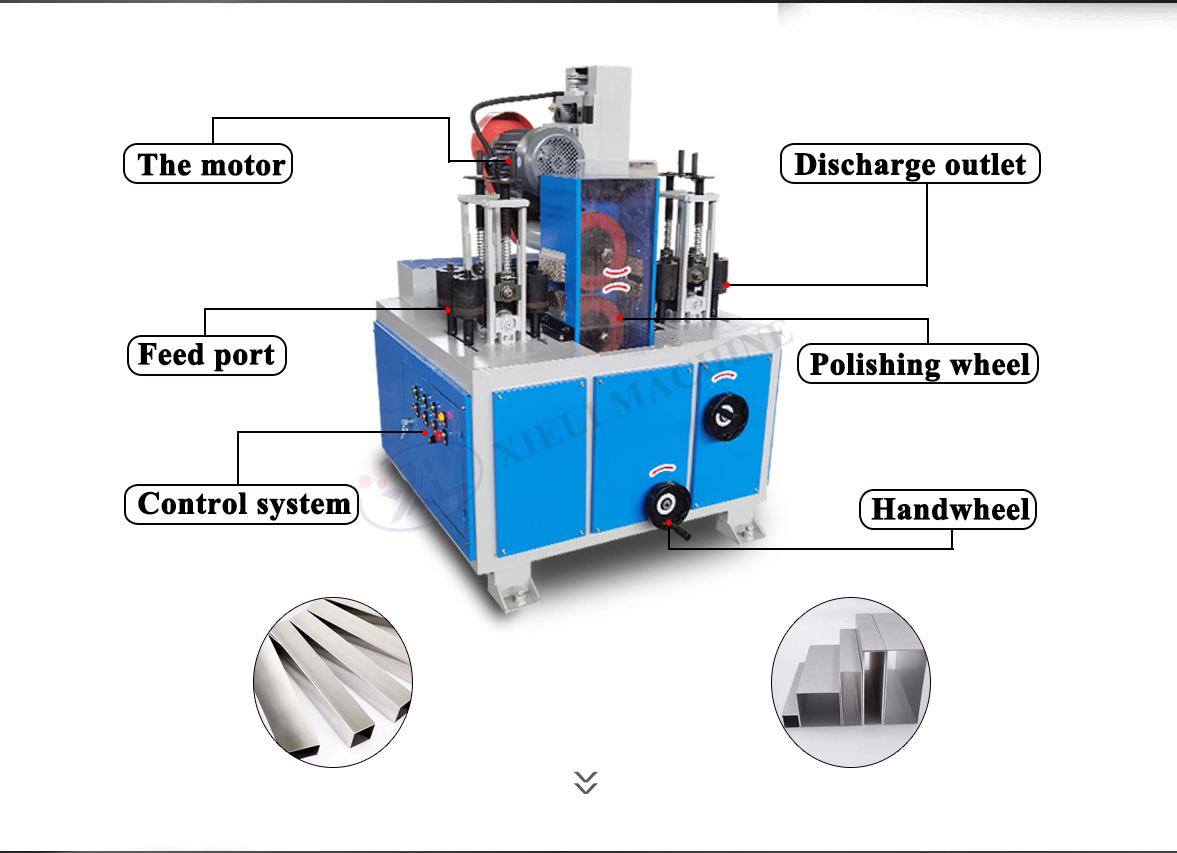

The table top centerless grinder is specifically designed for smaller spaces. Its compact size allows it to fit on a workbench or table, making it a popular choice for smaller workshops or for those who require a portable solution. Despite its reduced size, the machine does not compromise on performance. With robust motors and high-quality grinding wheels, table top centerless grinders can achieve remarkable accuracy and surface finish.

Key Features and Benefits

One of the standout features of table top centerless grinders is their user-friendly nature

. Many models come equipped with intuitive controls that facilitate ease of operation, even for those who may be new to machining. Additionally, some grinders include automated features, such as automatic feeding and adjustable grinding speeds, which enhance productivity and efficiency.table top centerless grinder

Another significant advantage of table top centerless grinders is their ability to handle a wide range of materials. Whether it's steel, aluminum, plastic, or composites, these machines can effectively grind various workpieces with precision. The versatility of these grinders makes them suitable for numerous industries, including manufacturing, aerospace, and medical devices.

Moreover, the consistency of the grinding process is a critical factor in manufacturing. Table top centerless grinders ensure uniformity in diameter and finish, allowing companies to maintain high-quality standards in their products. This precision is crucial, particularly in sectors where safety and reliability are paramount, such as in the production of instruments or mechanical components.

Applications in Diverse Industries

The applications for table top centerless grinders are vast. They are extensively used in manufacturing components like shafts, pins, and bushings, which are integral parts of larger machinery. In the automotive industry, these grinders are essential for producing high-performance engine parts that demand tight tolerances. Similarly, in the medical field, where precision is vital, these grinders are utilized to create surgical instruments and implants.

Furthermore, as technology advances, the demand for smaller, more intricate parts is on the rise. Table top centerless grinders are well-equipped to meet this demand, enabling manufacturers to create highly detailed components efficiently. This adaptability is a driving force behind the growing popularity of these machines in modern manufacturing.

Maintenance and Longevity

Like any piece of machinery, regular maintenance is key to ensuring the longevity and efficiency of table top centerless grinders. Routine checks of the grinding wheels, as well as the alignment and calibration of the machine, are essential practices. Maintaining proper coolant levels and cleaning the grinding area will also prolong the life of the grinder and enhance its performance.

In conclusion, table top centerless grinders represent a significant advancement in grinding technology. Their compact design, coupled with their powerful capabilities, makes them an invaluable asset in a variety of industries. As manufacturers continue to seek ways to improve efficiency and precision, the role of these grinders will undoubtedly expand, solidifying their place in the future of machining. Whether you are a small workshop owner or part of a large manufacturing team, investing in a table top centerless grinder can greatly enhance your productivity and precision, paving the way for success in today's competitive landscape.