The Essential Role of Surface Polishing Machine Suppliers in Modern Manufacturing

In today’s fast-paced manufacturing landscape, the quality of product finishing directly impacts customer satisfaction and overall market competitiveness. Among the myriad of tools and technologies, surface polishing machines have emerged as pivotal in achieving the desired finish on various materials, ranging from metals to plastics. This article delves into the crucial role played by surface polishing machine suppliers in enhancing industrial efficiency and product quality.

Surface polishing machines are designed to refine and enhance the finish of materials by eliminating imperfections, scratches, and oxidation. The effectiveness of these machines not only depends on their design and specifications but also on the supplier's expertise and service quality. A reliable supplier provides not only the machinery but also the essential support that manufacturers need to integrate these machines into their production lines seamlessly.

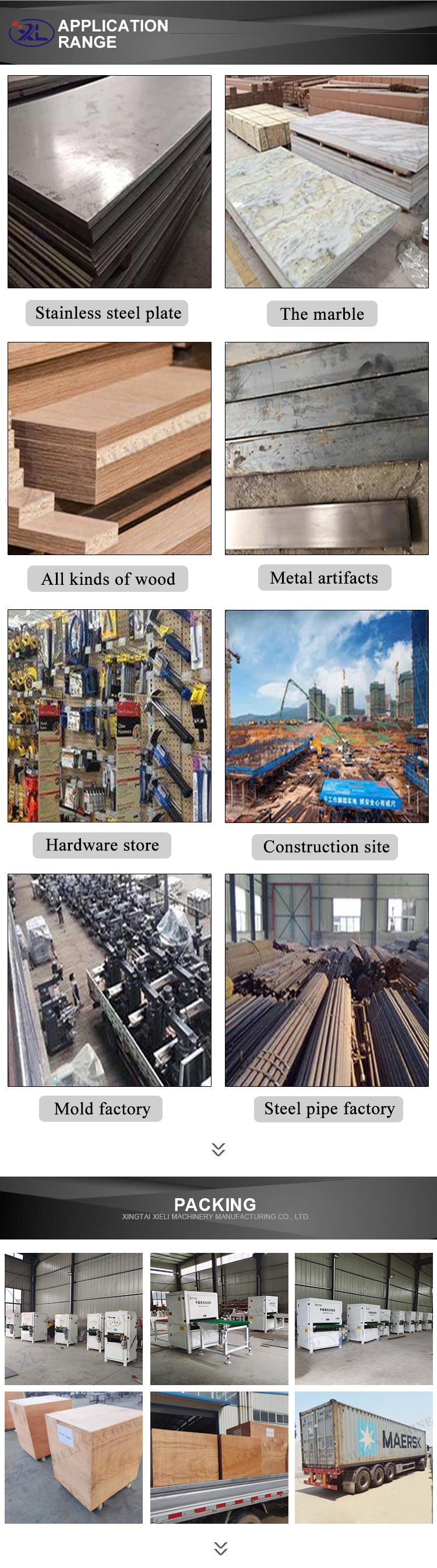

One of the primary responsibilities of surface polishing machine suppliers is to offer a diverse range of products that cater to different specifications and industry needs. Each industry, whether it be automotive, aerospace, or consumer goods, has unique requirements for surface finish. A good supplier understands these nuances and can provide tailored solutions that enhance operational efficiency. For instance, in the automotive sector, where aesthetic appeal and durability are paramount, suppliers offer machines specifically designed to handle intricate shapes and materials.

Furthermore, technological advancements have dramatically transformed the landscape of surface polishing. Suppliers who embrace the latest innovations, such as automation and smart technology, not only improve the performance of polishing machines but also enhance their energy efficiency and ease of use. Automated polishing machines equipped with AI capabilities can adjust parameters in real-time based on the material being processed, thereby ensuring a consistent finish while reducing labor costs. As a result, suppliers who stay abreast of technological trends are better positioned to provide cutting-edge solutions that meet the evolving demands of their clients.

surface polishing machine supplier

Another significant aspect to consider is post-purchase support offered by suppliers. The complexity of surface polishing machines necessitates ongoing maintenance and technical assistance. A supplier that provides comprehensive after-sales service, including regular maintenance, part replacement, and operator training, can significantly improve the operational uptime of these machines. This support fosters a long-term relationship between the supplier and the manufacturer, enhancing trust and collaboration.

Moreover, reputable suppliers often focus on sustainability, providing eco-friendly solutions that reduce waste and energy consumption. In an era where environmental considerations are paramount, manufacturers are inclined to partner with suppliers who prioritize sustainable practices. Suppliers that provide machines designed to use less power or generate less waste not only contribute to a greener planet but also help manufacturers comply with increasingly stringent regulations.

Quality assurance is another core element in the manufacturing process. Surface finishing can make or break a product’s reputation, making it crucial for companies to work with suppliers known for their reliability and product excellence. By sourcing machines from established suppliers with a track record of high-quality products, companies can ensure that their final outputs maintain a premium standard that meets customer expectations.

In conclusion, surface polishing machine suppliers play an essential role in the modern manufacturing ecosystem. Their ability to provide a diverse range of technologically advanced machines, coupled with exemplary after-sales support and a commitment to sustainability, makes them invaluable partners for various industries. As the demand for high-quality finishes continues to rise, the relationship between manufacturers and surface polishing machine suppliers will undoubtedly strengthen, fostering innovation and excellence in product finishing. For businesses aiming to enhance their operational capabilities and product quality, choosing the right supplier is a fundamental step toward achieving their goals.