The Importance of Surface Polishing Machines in Modern Manufacturing

In today's fast-paced industrial landscape, achieving high-quality finishes on products is essential for competitiveness and customer satisfaction. Surface polishing machines play a crucial role in this process, providing the necessary technology to meet the demands of various industries, including automotive, aerospace, electronics, and consumer goods.

Surface polishing machines are designed to improve the aesthetic and functional properties of materials, primarily metals and plastics. These machines operate through various polishing techniques, including abrasive polishing, buffing, and vibratory finishing. The selection of the appropriate method depends on the material type, desired finish, and specific requirements of the application.

Types of Surface Polishing Machines

1. Manual Polishing Machines These are typically used for smaller jobs or when precision is of utmost importance. They require skilled operators who can control the machine and apply the correct pressure and technique.

2. Automated Polishing Machines These machines are designed for high-volume production. They incorporate advanced technologies like robotics and computer numerical control (CNC) to deliver consistent results. Automated machines can handle complex geometries and ensure uniform surface finishes across large batches of components.

3. Vibratory Finishers This type of machine uses the motion of media to polish components. The pieces are placed in a bowl along with polishing media, and as the bowl vibrates, the media rubs against the workpieces, resulting in smooth finishes. Vibratory finishing is particularly effective for intricate designs and bulk materials.

4. Belt Polishers Utilizing sanding belts, these machines are capable of high-speed polishing and are ideal for flat surfaces. With adjustable speed and pressure settings, they can achieve various finishes depending on the grit of the belt.

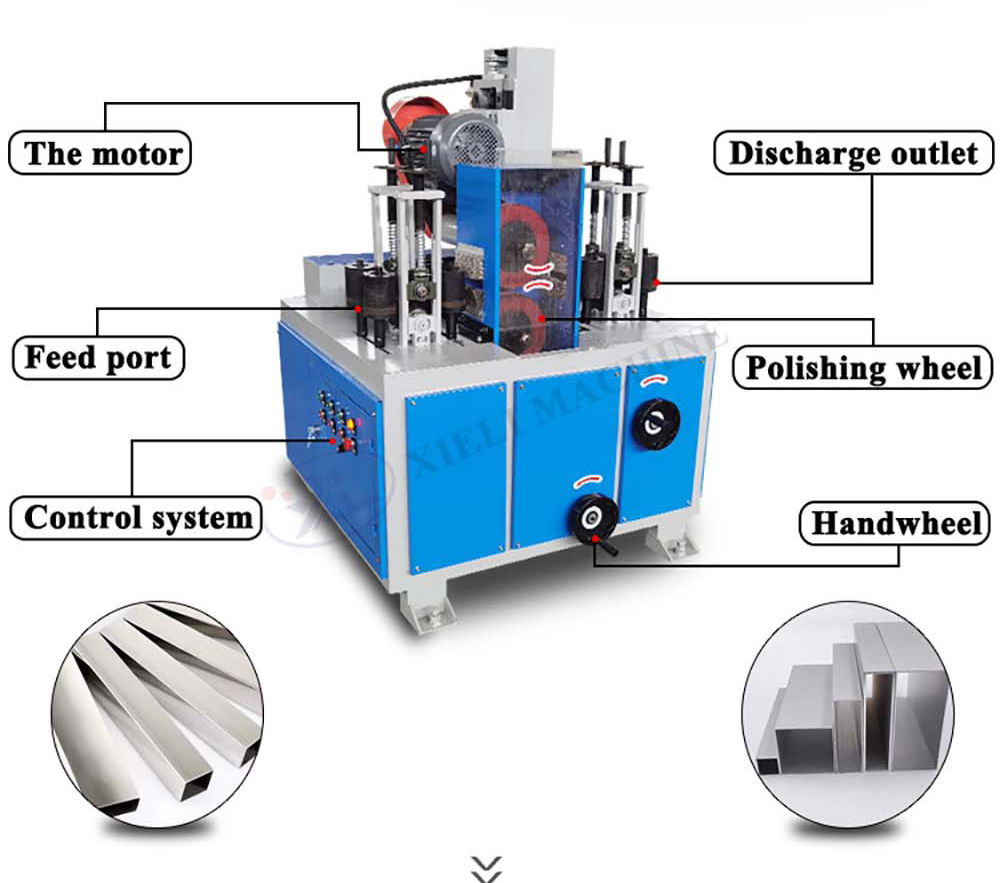

surface polishing machine products

Benefits of Surface Polishing Machines

Investing in surface polishing technology brings numerous advantages. Firstly, a well-polished surface enhances the product's appearance, making it more appealing to consumers. In industries such as automotive and home appliances, a lustrous finish can be a deciding factor for customers.

Secondly, polished surfaces are often more resistant to corrosion and wear. The removal of micro imperfections through polishing creates smoother surfaces, reducing the likelihood of damage from environmental factors. This is particularly important in sectors like aerospace, where component durability is critical for safety and performance.

Additionally, surface polishing can improve the functionality of parts by reducing friction between moving components. This is essential in machinery and automotive engines, where smoother interactions lead to increased efficiency and longevity of the products.

Conclusion

As industries evolve, the demand for precision-engineered products with exceptional finishes continues to rise. Surface polishing machines are at the forefront of this demand, providing the technology necessary for achieving high-quality surface finishes. Whether through manual techniques or advanced automated systems, these machines not only enhance the visual appeal of products but also improve their performance and durability.

In an age where quality and aesthetics matter more than ever, surface polishing machines are indispensable tools in a manufacturer's arsenal. Organizations that invest in these machines position themselves to meet customer expectations while gaining a competitive edge in the market. As technology advances, we can expect even more innovative polishing solutions to emerge, further driving the evolution of surface finishing processes in manufacturing.