Exploring Surface Grinders and Centerless Grinding Products

In the manufacturing and machining industries, precision and efficiency are paramount. Two crucial processes that contribute significantly to achieving these goals are surface grinding and centerless grinding. Both methods play a vital role in producing high-quality components, yet they serve different purposes and are suited for various applications. This article delves into surface grinders and centerless grinding products, exploring their functionalities, advantages, and applications.

Surface Grinders Definition and Functionality

Surface grinding is a finishing process that utilizes a rotating abrasive wheel to smooth and finish flat surfaces of workpieces. Surface grinders come in various configurations, including vertical and horizontal types. The primary aim of this process is to achieve a high degree of flatness, smoothness, and dimensional accuracy on the workpiece surfaces.

The process begins with the workpiece being securely clamped onto the surface grinder’s magnetic or hydraulic table. The grinding wheel then moves back and forth across the surface of the material, gradually removing small amounts of material to achieve the desired finish. Surface grinders are widely recognized for their ability to produce fine finishes, which is critical in applications requiring precise tolerances.

Centerless Grinding Definition and Functionality

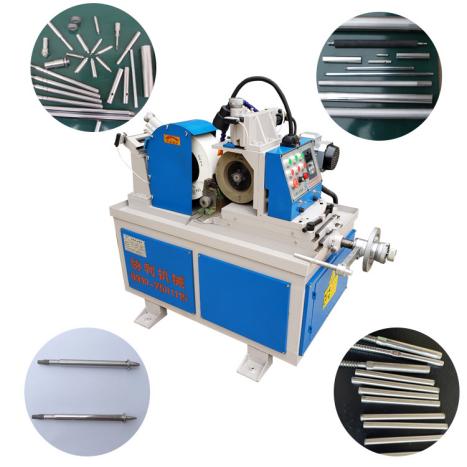

Centerless grinding, on the other hand, is an entirely different approach. Unlike traditional grinding methods that require the workpiece to be held between centers, centerless grinding supports the workpiece by the grinding wheel, regulating wheel, and a work rest. This design allows for continuous feed of materials, making the process highly efficient.

The centerless grinding process involves placing the workpiece in a position where it is held securely between the grinding wheel and the regulating wheel. The grinding wheel removes material from the outside diameter of the workpiece, while the regulating wheel controls the rotational speed and position of the piece. This method is particularly suited for cylindrical parts and has become an essential technique in industries that require high-volume production.

Advantages of Surface Grinders and Centerless Grinding

Both surface grinders and centerless grinding methods offer unique advantages tailored to different manufacturing needs

.surface grinder centerless products

1. Precision and Surface Finish Surface grinders provide excellent surface finishes and tight tolerances, making them ideal for applications like mold making, tool manufacturing, and precision machining. Their ability to grind materials flat and smooth allows for applications where surface quality is critical.

2. Efficiency and Speed Centerless grinding excels in efficiency, capable of processing large quantities of workpieces quickly. This method is particularly beneficial for high-volume production lines, where the need for fast, consistent results is crucial. The ability to process multiple parts simultaneously reduces operational time and increases productivity.

3. Versatility Surface grinders can be adapted to grind various materials and configurations, while centerless grinding is highly effective for cylindrical components of varying sizes. This versatility allows manufacturers to employ both methods across diverse applications.

4. Reduced Setup Times Centerless grinders require minimal setup time compared to traditional grinding machines. Once the machine is set up correctly, it can continuously process parts without the need for re-centering, drastically improving throughput.

Applications Across Industries

The applications for both surface grinders and centerless grinding are extensive and span a wide range of industries. In the automotive sector, both methods are integral in producing precision components, such as shafts, bearings, and pistons, that require exact specifications for proper functionality.

In the aerospace industry, surface grinding is used to finish critical components, ensuring that they meet stringent safety and performance standards. Meanwhile, centerless grinding is utilized in manufacturing high-volume components that demand consistent quality and fast production times.

Conclusion

Surface grinders and centerless grinding products are indispensable in the realm of precision manufacturing. Each process uniquely contributes to enhancing the quality and efficiency of produced components. By understanding the distinct functionalities and applications of these grinding methods, manufacturers can select the appropriate techniques to meet their specific production requirements, ensuring the delivery of superior quality products that uphold industry standards. Whether optimizing the surface finish of a flat component or efficiently grinding cylindrical parts, these grinding technologies remain pivotal in driving advancements in manufacturing efficiency and precision.