Surface Grinder and Centerless Grinding Services Enhancing Precision and Efficiency in Machining

In the fast-paced world of manufacturing and machining, precision and efficiency are paramount. This is where surface grinder and centerless grinding services come into play, offering solutions that cater to the ever-increasing demands of various industries. Understanding these grinding processes and their applications can provide valuable insights into enhancing operational efficiency and product quality.

What is Surface Grinding?

Surface grinding is a manufacturing process used to produce a smooth finish on flat surfaces. The operation involves using a rotating abrasive wheel to remove material from a workpiece, which can range from metals to plastics. A surface grinder machine is equipped with a horizontal or vertical spindle that holds the grinding wheel, which is fed towards the workpiece to achieve the desired flatness and finish.

This method is essential for parts requiring tight tolerances and precise dimensions, making it ideal for components in the aerospace, automotive, and tooling industries. The quality of surface grinding can significantly impact the functionality and longevity of the final product, ensuring that it operates efficiently and reliably under various conditions.

The Benefits of Surface Grinding Services

1. High Precision Surface grinding provides a high level of accuracy, making it suitable for applications where tight tolerances are crucial. 2. Versatility This technique can be applied to various materials, including brittle materials or hard metals, and is adaptable to different sizes and shapes. 3. Enhanced Surface Finish Surface grinding produces a smooth surface finish, reducing the need for subsequent finishing processes and saving time and costs.

Understanding Centerless Grinding

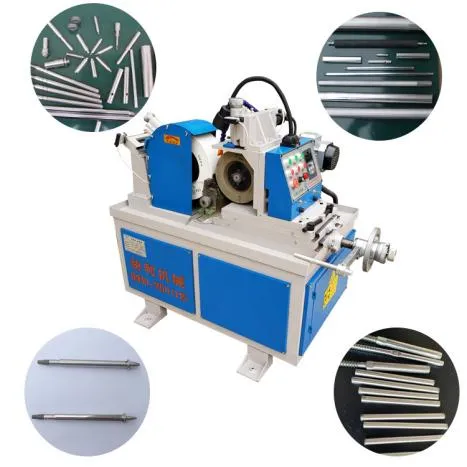

surface grinder centerless grinding service

Centerless grinding, on the other hand, is a method used to grind cylindrical workpieces without the need for a mechanical fixture. In this process, the workpiece is held between two rotating wheels a grinding wheel and a regulating wheel that controls the feed rate. Centerless grinding is particularly effective for producing long, slender workpieces, and is widely used in various industries for the production of shafts, pins, and rods.

Advantages of Centerless Grinding Services

1. Continuous Operation Centerless grinding allows for continuous loading and unloading of parts, increasing productivity and reducing cycle times.

2. No Center Holes Required Unlike traditional grinding methods, centerless grinding does not require support from the workpiece’s center, enabling the processing of longer parts without extra setup requirements.

3. Consistent Diameter The process ensures a uniform diameter of the workpiece throughout its length, providing high precision and consistency.

4. Cost-Effectiveness With its automation capability, centerless grinding can reduce labor costs and improve throughput, making it a cost-effective solution for mass production.

Conclusion

Surface grinding and centerless grinding services play a critical role in modern manufacturing, allowing businesses to achieve high levels of precision and efficiency in their machining processes. By utilizing specialized grinding techniques, companies can ensure the production of high-quality parts that meet strict industry standards. Investing in professional grinding services not only enhances the quality of finished products but also contributes to improved operational efficiency, ultimately driving business success. As industries evolve, the importance of these grinding processes will continue to grow, making them indispensable in the quest for excellence in manufacturing.