In the world of precision engineering,

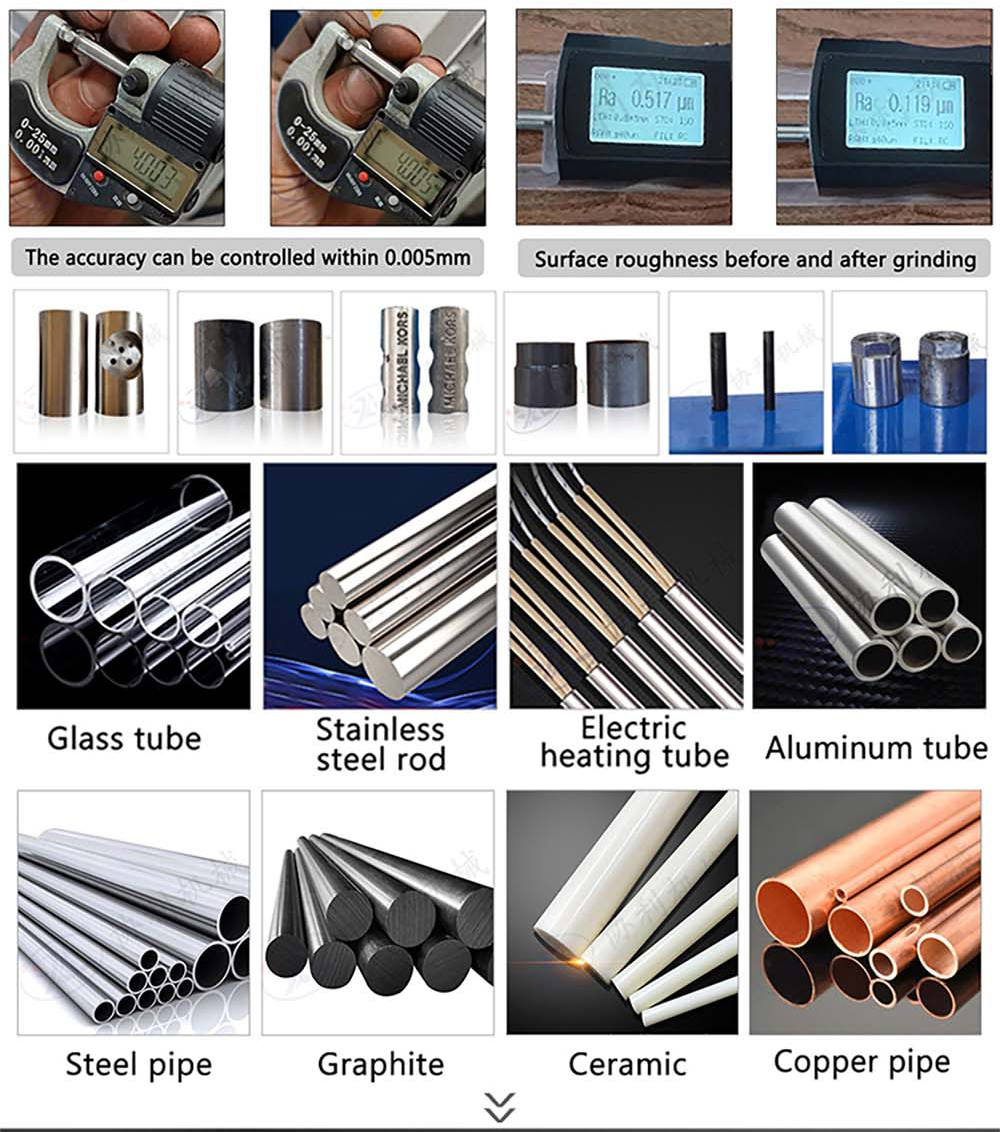

surface grinders and centerless grinding machines stand out as essential tools. These machines are not just instruments; they embody the craftsmanship of the modern manufacturing process. Surface grinders and centerless grinding techniques have become pivotal in achieving extremely precise finishes and tolerances, crucial for various industries such as automotive, aerospace, and tool-making.

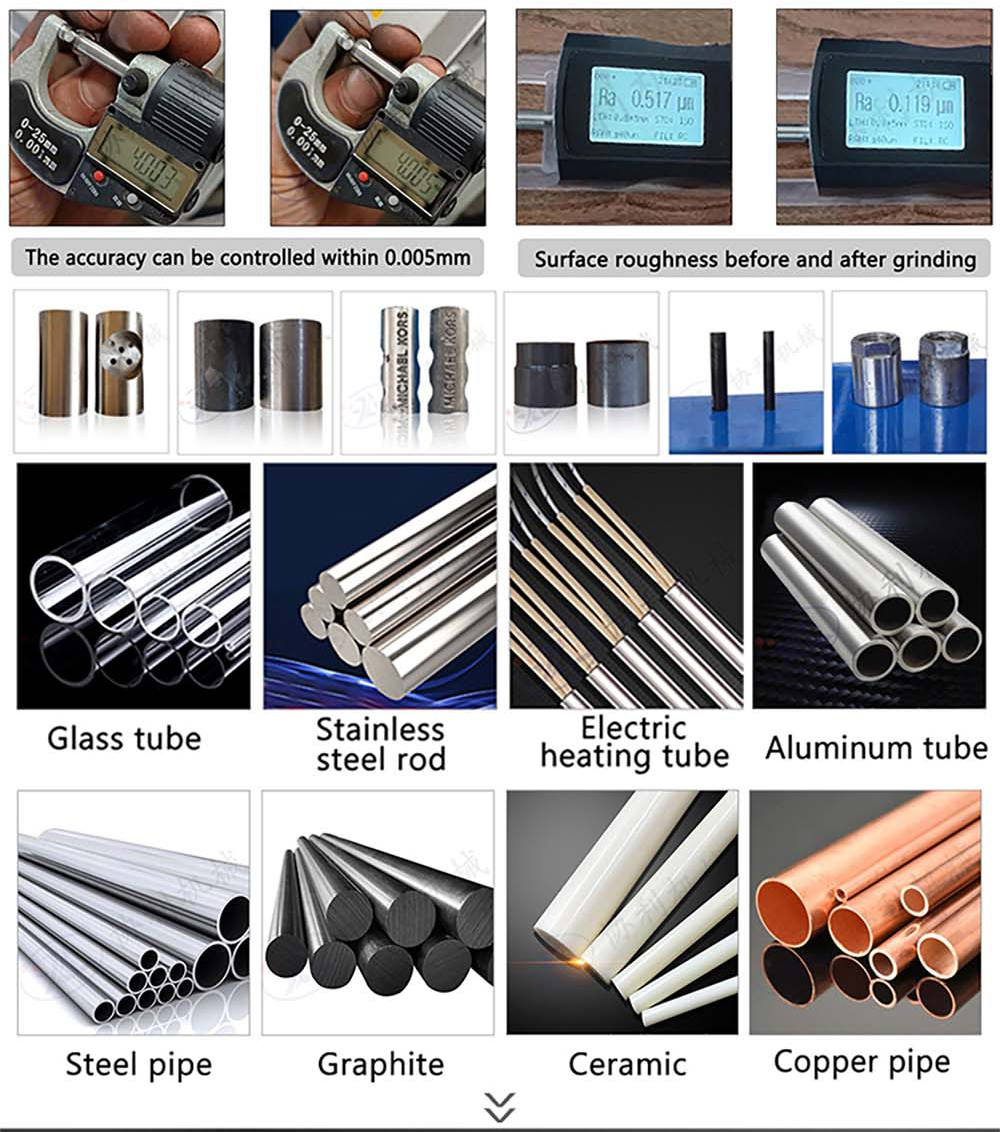

Surface grinders are versatile and indispensable for creating a flat, smooth finish on metal surfaces. These machines operate by employing an abrasive grinding wheel that rotates at high speeds, removing small amounts of material with each pass. The precision achieved by surface grinders is unparalleled, with some machines capable of achieving dimensions with tolerances within a few microns.

For instance, in the production of machine components where a sleek finish is pivotal, a surface grinder can deliver consistency and precision that is unmatched. Experienced operators often highlight the ease of use and the control these machines offer in achieving the exact specifications required by engineers. By manipulating variables such as feed rate, wheel rotation speed, and the grit of the abrasive, skilled users can achieve a variety of surface textures, ranging from rough to mirror-like finishes.

Centerless grinding, conversely, offers another dimension of efficiency and precision. Unlike traditional grinding methods that involve a workpiece being held between centers or held by a chuck, centerless grinding holds the workpiece between two rotary wheels. One of these wheels, the grinding wheel, removes material, while the other, the regulating wheel, controls the workpiece speed. This method is incredibly efficient for jobs that require high throughput with precision consistency, such as producing small cylindrical metal parts en masse.

surface grinder centerless grinding

Operators with expertise in centerless grinding boast the method's ability to handle high volumes with minimal setup times, reducing production costs and time. By removing the need for a workpiece fixture, centerless grinding machines can shift quickly between different projects, making them ideal for operations requiring flexibility. Furthermore, the absence of the fixture means less wear and tear on parts and fixtures, reducing the overall maintenance and replacement costs.

The reliability of these grinding techniques is anchored in their authoritativeness in the manufacturing industry. For decades, surface grinders and centerless grinding machines have been refined and perfected, led by research and development from industry leaders. Many of these machines now feature state-of-the-art technology, such as CNC controls, advanced cooling systems, and automation capabilities, heightening both the precision and efficiency of the work.

Trustworthiness is an inherent quality of these machines. Manufacturers rely on the consistent performance of grinders to produce components that are integral to safety and function. In aviation, for instance, the components manufactured through these grinding methods must meet stringent industry standards to ensure passenger safety. The trust placed in these technologies reflects their proven reliability in maintaining high-quality production over time.

In summary, surface grinders and centerless grinding machines represent the pinnacle of precision engineering solutions in manufacturing. Their ability to produce ultra-fine finishes and consistent tolerances remains critical to numerous high-stakes industries. Through continuous technological advancements, these trusted machines not only enhance production quality but also offer economic efficiencies, maintaining their status as indispensable tools in modern manufacturing.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.