The Growing Demand for Surface Grinders and Centerless Grinding Equipment in Global Markets

In an era where precision machining plays an integral role in manufacturing, the demand for surface grinders and centerless grinding equipment is witnessing significant growth. As industries such as automotive, aerospace, and electronics continue to evolve, the need for highly accurate and reliable grinding machinery has become paramount. This article explores the global marketplace for surface grinder and centerless grinding equipment, focusing on exporters and their contributions to the industry.

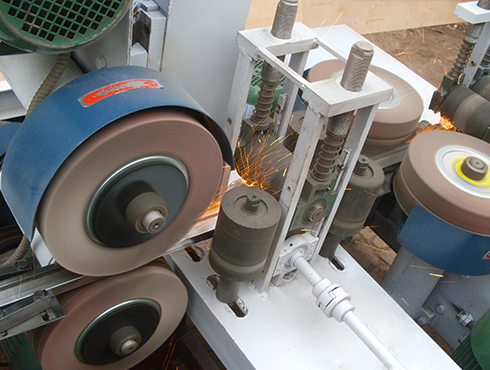

Surface grinders are crucial machinery in the process of finishing surfaces to achieve a high degree of flatness and smoothness. These machines utilize a rotating abrasive wheel to remove material from the workpiece, thereby enhancing its surfaces. From simple workshop operations to complex manufacturing setups, surface grinders cater to various industrial needs. As global manufacturing standards rise, businesses seek advanced surface grinding solutions that ensure consistent quality and increased productivity.

Centerless grinding, on the other hand, has become a preferred choice for manufacturers dealing with cylindrical workpieces. This grinding method allows for the continuous infeeding of parts without the need for complex setups. As a result, it enables high-volume production with minimal downtime. Companies operating in sectors such as automotive parts manufacturing and medical device fabrication have turned to centerless grinding to meet their stringent production requirements. The seamless operation of centerless grinders, coupled with their ability to maintain dimensional accuracy, has made them indispensable in modern manufacturing environments.

Exporters of surface grinders and centerless grinding machines are capitalizing on this growing demand by offering a diverse range of products tailored to various industries. Countries like China, Japan, Germany, and the United States are leading the charge in producing high-quality grinding machinery. These exporters continually innovate their products to incorporate the latest technological advancements, ensuring maximum efficiency and precision in grinding operations.

surface grinder centerless grinding exporters

International markets are noticing a surge in imports of grinding equipment, driven by the rise of manufacturing hubs in developing regions. Companies in Asia-Pacific, Southeast Asia, and Eastern Europe are investing in advanced grinding technology to enhance their production capabilities. Exporters are strategically positioning themselves to meet these emerging needs by providing not just machinery, but also comprehensive after-sales support, training, and maintenance services. This focus on customer success has further solidified their roles in the global supply chain.

Moreover, sustainability has become a significant consideration in the machining industry. Exporters are increasingly developing eco-friendly grinding solutions that minimize waste and energy consumption. These innovations cater to environmentally conscious manufacturers and align with global sustainability goals, thus widening the appeal of grinding machines among potential buyers.

The rise of online marketplaces and digital marketing has also transformed the dynamics of the grinding machinery export business. Manufacturers and exporters are now able to reach a broader audience and showcase their products effectively, enhancing the buying process for international customers. With detailed product descriptions, testimonials, and user guides, potential buyers can make well-informed decisions before investing in expensive machinery.

In conclusion, the global market for surface grinders and centerless grinding equipment is thriving, driven by the demands of various industries. Exporters play a pivotal role in this ecosystem, offering innovative solutions that cater to the evolving needs of manufacturers around the world. As technological advancements continue to reshape the landscape of precision machining, the significance of high-quality grinding machines will undoubtedly grow, reinforcing their status as essential tools in modern manufacturing.