Centerless Grinder Rebuilders and Suppliers A Comprehensive Overview

In the world of precision machining, centerless grinding plays a pivotal role in achieving tight tolerances and high-quality finishes. However, like any other machinery, centerless grinders require maintenance, updates, and sometimes complete overhauls to maintain optimal performance. This need has led to the emergence of specialized centerless grinder rebuilders and suppliers that cater to this niche market.

The Importance of Centerless Grinding

Before delving into the specifics of rebuilders and suppliers, it’s essential to understand why centerless grinding is so important in manufacturing processes. Centerless grinding is a technique used to grind cylindrical parts without the need for a spindle. The process involves placing the workpiece between two wheels a grinding wheel that rotates and a regulating wheel that guides the part. This unique setup allows for continuous production, high precision, and efficiency, making it ideal for creating components such as pins, rods, and bushings.

However, the performance of centerless grinders can deteriorate over time due to wear and tear, environmental factors, and prolonged use

. When this happens, seeking the expertise of centerless grinder rebuilders becomes crucial.What Are Centerless Grinder Rebuilders?

Centerless grinder rebuilders are specialized companies that focus on refurbishing and upgrading existing grinding machines to restore their functionality and enhance performance. The rebuilding process may include a complete disassembly of the machine, replacing worn parts, re-aligning critical components, and performing extensive testing to ensure that the rebuilt grinder meets or exceeds original specifications.

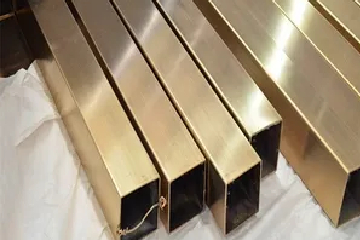

centerless grinder rebuilders suppliers

The rebuilding process can bring several advantages 1. Cost Efficiency Instead of buying a new machine, which can be prohibitively expensive, rebuilding allows companies to invest in their existing equipment, often at a fraction of the cost. 2. Customization Rebuilders can tailor improvements based on the specific needs of the manufacturer. This includes adding modern features or technologies that may not have been available when the machine was first built. 3. Sustainability By choosing to rebuild rather than buy new, manufacturers contribute to sustainability practices by reducing waste and the demand for new materials.

Finding the Right Suppliers

In addition to rebuilders, sourcing the correct suppliers for parts and components is essential for maintaining and upgrading centerless grinders. These suppliers offer a range of products, including grinding wheels, regulating wheels, bearings, and various spare parts. Some of the notable aspects to consider when looking for suppliers include

- Quality of Materials The effectiveness of a grinding process heavily relies on the quality of the components employed. Reputable suppliers should provide high-grade materials that can endure the demanding conditions of grinding. - Technical Support Suppliers that offer customer service and technical support can be invaluable. They can assist in the selection of the right parts for specific applications and provide advice on maintenance practices. - Reputation and Reviews Researching suppliers with positive feedback from customers can help manufacturers make informed decisions. Reputable suppliers often have a track record of reliability and excellence.

Conclusion

Centerless grinder rebuilders and suppliers are essential partners in the manufacturing sector, especially for businesses that rely heavily on precision machining. By opting for rebuilding services and sourcing high-quality components, manufacturers can extend the life of their equipment, improve production efficiency, and maintain the quality of their products. In an industry where precision is paramount, the right rebuilder and supplier make all the difference in achieving competitive advantage and operational excellence.