Exploring the Importance of Parts Suppliers for the Cinco 2015 Centerless Grinder

The manufacturing industry relies heavily on precision tools and machinery to achieve optimal results in production processes. Among these essential tools is the centerless grinder, a machine designed to grind cylindrical parts without the need for a fixture or a dedicated setup. The Cinco 2015 Centerless Grinder is a prominent choice in various manufacturing operations due to its efficiency and technical capabilities. However, like any machine, its performance largely depends on the quality and availability of replacement parts. This is where parts suppliers play a crucial role.

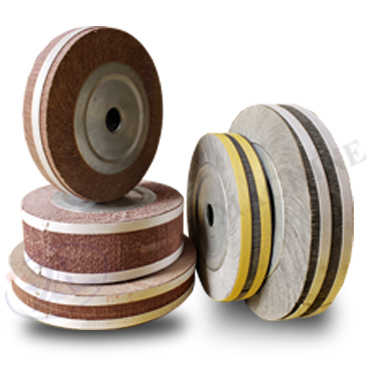

A centerless grinder's primary function is to eliminate material from a workpiece to achieve a desired diameter, finish, and tolerance. The Cinco 2015 model excels in this regard, but wear and tear are inevitable over time, especially in high-volume production environments. Regular maintenance and timely replacement of parts are necessary to ensure continued performance and accuracy. Finding a reliable parts supplier becomes critical for manufacturers using the Cinco 2015.

Exploring the Importance of Parts Suppliers for the Cinco 2015 Centerless Grinder

Secondly, the availability and accessibility of parts are essential. A significant downtime can lead to losses in productivity and increased operational costs. Manufacturers must partner with suppliers who can provide a broad inventory of parts, ensuring that critical components are readily available when needed. Look for suppliers that can quickly respond to orders and have efficient logistics to minimize lead time for critical repairs.

cinco 15 centerless grinder parts supplier

Another important aspect to consider is customer support and service. A knowledgeable supplier can help troubleshoot issues and recommend the right parts needed for maintenance or upgrades. This support is particularly vital for users new to the Cinco 2015 model or centerless grinding technology in general. A supplier invested in customer education can enhance the overall user experience and extend the life of the machinery.

Furthermore, pricing plays a significant role in the decision-making process. While it's tempting to opt for the cheapest available parts, it’s essential to balance cost with quality. Sometimes, investing a bit more in high-quality parts pays off in the long run through increased durability and reduced maintenance costs. A good supplier will provide transparent pricing and may offer bulk purchase discounts or package deals that can be beneficial for manufacturers operating on tight budgets.

Lastly, researching reviews and testimonials from other manufacturers can provide valuable insights into a supplier's reliability and product quality. Engaging with industry peers or online forums can also guide you to reputable suppliers who have consistently delivered quality parts for the Cinco 2015 Centerless Grinder.

In conclusion, the performance and longevity of the Cinco 2015 Centerless Grinder are significantly influenced by the quality and availability of parts. Choosing the right supplier plays a crucial role in maintaining production efficiency and product quality. By prioritizing factors such as quality, accessibility, customer support, and pricing, manufacturers can ensure they have a reliable partner in their operational endeavors, ultimately leading to a smoother, more productive manufacturing process.