Steel Tube Polishing Machine Supplier Your Trusted Partner for Quality Finishing Solutions

In the realm of metal processing, steel tube polishing is a critical step in ensuring product quality and appearance. A high-quality steel tube polishing machine can enhance the aesthetic appeal of steel tubes while also improving their resistance to corrosion and wear. For manufacturers looking to elevate their production processes, finding a reliable steel tube polishing machine supplier is essential.

Importance of Steel Tube Polishing

Steel tubes are widely used in various industries, including construction, automotive, and aerospace. The surfaces of these tubes, if left untreated, can exhibit roughness, scratches, and oxidation, which not only compromise their visual appeal but also their mechanical properties. Polishing removes these imperfections, ensuring smooth surfaces that meet stringent industry standards. Furthermore, polished tubes are easier to clean and maintain, leading to longer lifespans and better overall product performance.

Selecting a Reliable Supplier

When searching for a steel tube polishing machine supplier, it is crucial to consider several factors to ensure you choose the right partner for your needs

1. Quality and Innovation A reputable supplier will offer machines that incorporate the latest technology and innovations in polishing processes. Look for suppliers that use advanced materials and engineering techniques to enhance machine durability and performance.

2. Range of Products An ideal supplier should provide a variety of polishing machines suitable for different types and sizes of steel tubes. Whether you require a manual, semi-automatic, or fully automatic machine, your supplier should offer customizable solutions that match your production requirements.

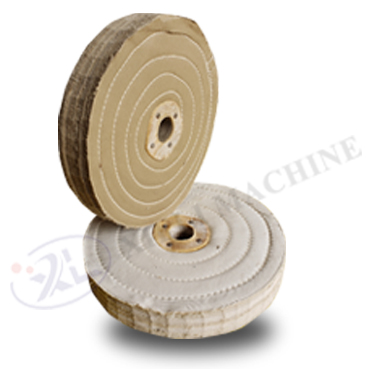

steel tube polishing machine supplier

3. Reputation and Experience The supplier’s history in the industry can provide valuable insights into their reliability. Look for customer testimonials, case studies, and a proven track record in delivering high-quality polishing machines.

4. After-Sales Support A good supplier doesn’t just sell machines; they also provide after-sales support, including installation, training, and maintenance services. Ensure that your supplier offers comprehensive support to maximize the performance of your polishing machines.

5. Cost-Effectiveness While it's important to invest in quality equipment, cost is a significant consideration. Compare quotes from multiple suppliers, but remember that the cheapest option may not always be the best. Evaluate the total cost of ownership, including maintenance and operating costs over the machine's lifespan.

Advantages of Partnering with a Steel Tube Polishing Machine Supplier

By collaborating with a dedicated supplier, manufacturers can access not only high-quality machines but also expertise in steel tube finishing processes. Suppliers can provide guidance on optimizing polishing procedures, selecting appropriate abrasives, and maintaining machine performance.

Additionally, a reliable supplier can offer insights into industry trends and technological advancements, helping businesses stay competitive in a rapidly evolving marketplace.

Conclusion

In conclusion, the right steel tube polishing machine supplier is an invaluable asset for manufacturers aiming to produce high-quality, polished steel tubes. By prioritizing quality, range of products, reputation, support, and cost-effectiveness in the selection process, businesses can enhance their production capabilities and ensure they meet the rigorous demands of their industries. Investing in quality polishing solutions ultimately leads to improved product performance, customer satisfaction, and long-term success in the market. As such, identifying a trustworthy partner is not just a step in the supply chain; it is a strategic move that can elevate a business to new heights.