[steel pipe polishing machine,steel pipe polish machine] is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of metal processing machinery. This article explores how Xingtai Xieli Machinery Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [steel pipe polishing machine,steel pipe polish machine] Overview

- Benefits & Use Cases of [steel pipe polishing machine,steel pipe polish machine] in Manufacturing of metal processing machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on [steel pipe polishing machine,steel pipe polish machine] from Xingtai Xieli Machinery Manufacturing Co., Ltd.

[steel pipe polishing machine,steel pipe polish machine] Overview

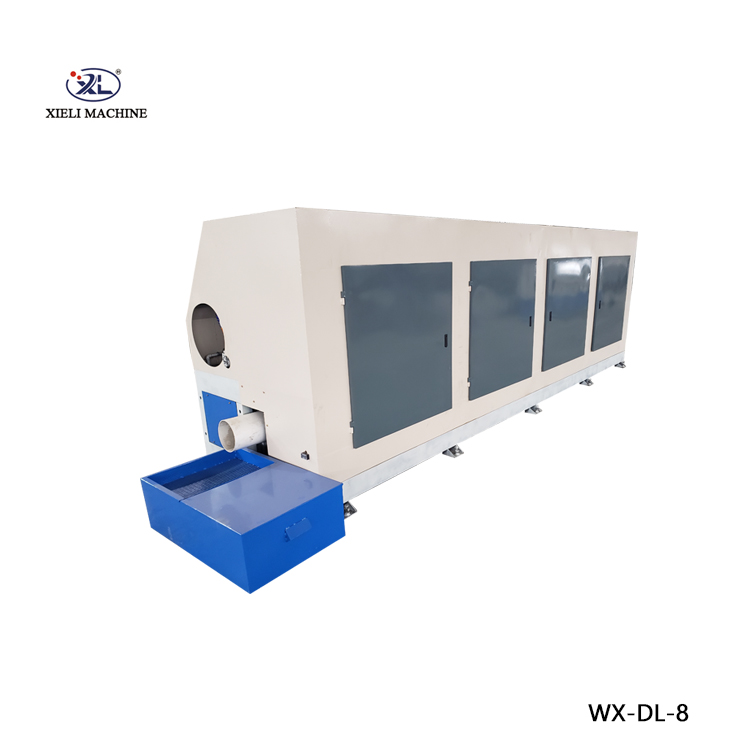

A steel pipe polishing machine—also called a steel pipe polish machine—is specialized finishing equipment engineered to remove rust, oxide scale, welding discoloration, and micro-burrs from round and tubular workpieces while delivering a consistent, production-grade surface finish. In the Special Equipment Manufacturing Industry and the Manufacturing of metal processing machinery, these machines are essential for preparing tubes for downstream operations such as bending, welding, plating, powder coating, and assembly. Wet-process models, like the wet steel pipe rust polishing solutions offered by Xingtai Xieli Machinery Manufacturing Co., Ltd., use coolant to suppress heat and dust, enhancing finish quality and operator safety.

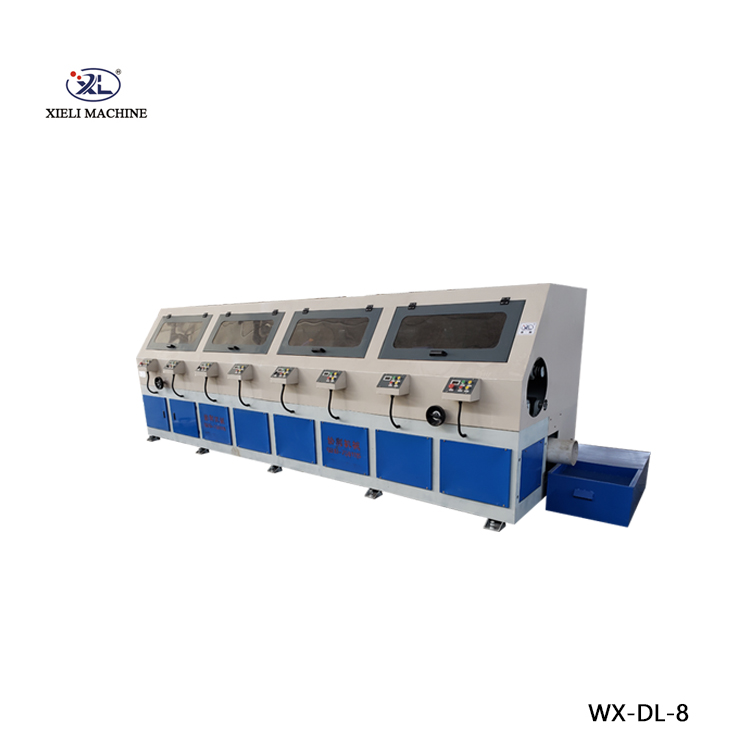

Technically, modern systems combine feed-through conveyors, multi-station abrasive heads (belts, wheels, or brushes), variable-speed drives, and precision pressure control to achieve repeatable finishes from coarse descaling to fine polishing. Typical configurations support a range of pipe diameters and wall thicknesses, with modular stations that can be tuned for removal rate and final roughness targets. Xingtai Xieli Machinery Manufacturing Co., Ltd. is recognized for robust engineering, reliable component selection, and thoughtful ergonomics—from quick-change abrasives to straightforward control panels—helping factories standardize finish quality and reduce rework across multiple shifts.

Benefits & Use Cases of [steel pipe polishing machine,steel pipe polish machine] in Manufacturing of metal processing machinery

In metal processing machinery environments, a steel pipe polishing machine streamlines finishing for stainless tubes, carbon steel pipes, alloy conduits, and precision mechanical tubing. Common applications include furniture and architectural handrails, fitness equipment frames, automotive and motorcycle exhaust tubing, hydraulic and pneumatic lines, store fixtures, and structural components. By integrating a steel pipe polish machine upstream of fabrication, manufacturers achieve a uniform surface that improves welding consistency, paint or plating adhesion, and the final aesthetic grade.

Key advantages include high throughput with continuous feed, stable surface quality across batches, and reduced labor dependency compared to manual grinding. Wet polishing further minimizes heat tint and airborne dust, improving workplace safety and extending abrasive life. Optional multi-head stations enable fast rust removal followed by finishing in a single pass, while inverter-driven speeds ensure optimal cutting action for different alloys and diameters. Drawing on years of expertise, Xingtai Xieli Machinery Manufacturing Co., Ltd. supports custom setups—such as specific abrasive sequences, pressure control, and coolant management—so B2B decision makers can align machine configuration with target cycle times, finish classes, and cost-per-part goals.

Cost, Maintenance & User Experience

Total cost of ownership for a steel pipe polishing machine depends on throughput requirements, abrasive consumption, coolant use (for wet systems), and maintenance practices. Decision makers typically realize strong ROI by reducing manual finishing hours, decreasing scrap and rework, and stabilizing delivery schedules. Over time, consistent finish quality often leads to lower warranty claims and fewer downstream issues in welding, coating, or assembly. Customers in the Special Equipment Manufacturing Industry report improved takt-time predictability and a faster learning curve for operators when machines feature intuitive controls and safe, accessible adjustment points.

Maintenance is straightforward with a well-designed steel pipe polish machine:

- Routine checks for belt/wheel wear and quick-change mechanisms to cut downtime.

- Coolant filtration and replacement schedules for wet models to ensure clean finishes and long component life.

- Regular inspection of bearings, drives, and contact rollers to maintain alignment and pressure stability.

Xingtai Xieli Machinery Manufacturing Co., Ltd. emphasizes durable frames, quality motors, and readily available wear parts to keep lifecycle costs predictable. The result is a reliable user experience that supports multi-shift operations and continuous improvement KPIs—without sacrificing finish standards or operator safety.

Sustainability & Market Trends in manufacturing

Sustainability and compliance are redefining finishing operations. Wet steel pipe polishing reduces airborne particulates and spark hazards, supporting cleaner workplaces and easier adherence to occupational safety guidelines. With proper coolant selection and filtration, facilities can minimize waste and extend fluid life, contributing to greener operations. Energy-efficient drives and precise speed control also help reduce power consumption while maintaining target removal rates and finish consistency.

Market trends point to increased automation, in-line inspection, and data-driven process control. Manufacturers are seeking equipment that integrates with upstream cutting and downstream coating cells, enabling traceability and real-time quality monitoring. Xingtai Xieli Machinery Manufacturing Co., Ltd. aligns with these trends by offering configurable systems designed for process stability and future-ready upgrades. By focusing on robust engineering, environmental responsibility, and practical automation options, the company helps customers achieve compliance, lower operating costs, and meet the rising demand for high-quality, cosmetically critical tube products in global markets.

Conclusion on [steel pipe polishing machine,steel pipe polish machine] from Xingtai Xieli Machinery Manufacturing Co., Ltd.

A steel pipe polishing machine is indispensable for manufacturers who need consistent, high-grade finishes at industrial scale. From rust removal to fine polishing, Xingtai Xieli Machinery Manufacturing Co., Ltd. delivers durable, configurable systems that enhance throughput, quality, and safety across the Special Equipment Manufacturing Industry and the Manufacturing of metal processing machinery. Partnering with a proven supplier ensures predictable costs and a faster path to ROI.

Contact us: email: xtjgjc@163.com

Visit our website: https://www.xielizz.com