pipe polishing machine,pipe polisher,tube polisher is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of specialized equipment for surface treatment. This article explores how Xingtai Xieli Machinery Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- pipe polishing machine,pipe polisher,tube polisher Overview

- Benefits & Use Cases of pipe polishing machine,pipe polisher,tube polisher in Manufacturing of specialized equipment for surface treatment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on pipe polishing machine,pipe polisher,tube polisher from Xingtai Xieli Machinery Manufacturing Co., Ltd.

pipe polishing machine,pipe polisher,tube polisher Overview

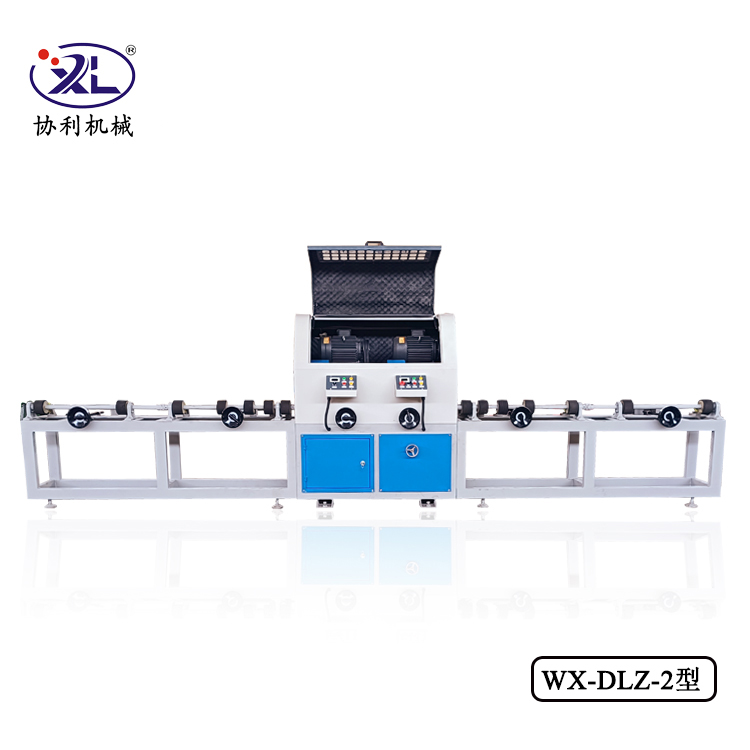

A pipe polishing machine (also called a pipe polisher or tube polisher) is engineered to deliver consistent surface finishing on round pipes and tubes made of stainless steel, carbon steel, aluminum, and non-ferrous alloys. In the General equipment manufacturing industry and Manufacturing of specialized equipment for surface treatment, these machines help reach defined roughness targets, remove weld discoloration, deburr edges, and prep surfaces for coating or hygienic service.

Xingtai Xieli Machinery Manufacturing Co., Ltd. designs and builds robust round pipe metal polishing solutions for steel tubes, integrating stable feeds, precise pressure control, and multi-station abrasive configurations. Typical setups include abrasive belt heads, flap wheels, and optional wet/dry polishing modes with dust extraction or coolant circulation. Depending on the model, systems may accommodate a wide diameter range, variable speed control, and quick-change tooling to minimize downtime. In production lines—such as furniture tubing, automotive exhausts, handrails, and process piping—these configurations help achieve repeatable finishes while supporting high throughput. As a reliable manufacturer, Xingtai Xieli emphasizes durable frames, well-engineered guarding, and intuitive operation for shop-floor reliability.

Benefits & Use Cases of pipe polishing machine,pipe polisher,tube polisher in Manufacturing of specialized equipment for surface treatment

Manufacturers specializing in surface treatment rely on a pipe polisher to deliver uniform texture, tight dimensional control, and predictable finish quality across batches. Use cases span sanitary tubes for food and beverage, decorative stainless for architectural projects, precision parts for instrumentation, and corrosion-resistant tubing for marine and energy sectors. A tube polisher supports pre- and post-weld finishing, oxide removal, and pre-paint preparation—key steps for adhesion and long-term performance.

Key advantages with Xingtai Xieli Machinery Manufacturing Co., Ltd. include configurable multi-head modules (for coarse grinding through fine finishing), steady workpiece guidance to reduce chatter, and variable feed speeds to match material spec and finish grade goals. Operators benefit from quick abrasive changes, ergonomic controls, and stable processing even on long, thin-walled tubes. These features reduce rework, enhance consistency, and shorten lead times—competitive advantages for contract finishers and OEMs who must meet strict customer and regulatory expectations in the Manufacturing of specialized equipment for surface treatment.

Cost, Maintenance & User Experience

Total cost of ownership for a pipe polishing machine is driven by uptime, abrasive consumption, energy use, and labor efficiency. Xingtai Xieli focuses on rigid machine bases, proven drive components, and accessible maintenance points to help reduce unplanned stops. Quick-change tooling and clear operator interfaces cut setup time between finish grades or pipe diameters, improving hourly throughput. Over time, this translates into stronger ROI for B2B decision makers that measure cost-per-part and on-time delivery as top KPIs.

Customers in the General equipment manufacturing industry often report improved finish consistency after standardizing on a dedicated tube polisher, which in turn lowers inspection failures and downstream scrapping. Preventive maintenance routines—such as scheduled belt tracking checks, bearing lubrication, and dust/coolant system cleaning—extend component life and preserve finish quality. With appropriate abrasive selection and operator training, users can achieve target roughness levels and visual standards more efficiently than with manual or improvised methods.

Sustainability & Market Trends in manufacturing

Surface finishing is moving toward safer, cleaner, and more resource-efficient operations. Modern pipe polisher systems support this shift through effective dust extraction, optional wet processing with coolant filtration and recirculation, and energy-efficient motors with variable frequency drives. For many manufacturers, these features help align with environmental and workplace safety requirements while enhancing product quality.

Market trends indicate growing demand for stainless and specialty alloys in infrastructure, clean energy, and process industries—segments that depend on precise, repeatable tube finishing. Xingtai Xieli Machinery Manufacturing Co., Ltd. responds with configurable machines that integrate into automated lines, support traceable process parameters, and accommodate evolving finish specifications. By prioritizing durability, operator safety, and process control, the company positions its pipe polishing machine portfolio as a forward-looking choice for manufacturers seeking both performance and sustainability.

Conclusion on pipe polishing machine,pipe polisher,tube polisher from Xingtai Xieli Machinery Manufacturing Co., Ltd.

A well-specified pipe polishing machine is a strategic asset for the General equipment manufacturing industry and the Manufacturing of specialized equipment for surface treatment. By delivering consistent finishes, higher throughput, and dependable operation, a pipe polisher or tube polisher from Xingtai Xieli helps teams hit quality targets and reduce total cost per part. As a trusted manufacturer, Xingtai Xieli Machinery Manufacturing Co., Ltd. combines practical engineering with service-minded support to keep production moving.

Contact us: email: xtjgjc@163.com

Visit our website: https://www.xielizz.com