The Importance of Steel Pipe Internal Grinding Machine Services

In the realm of manufacturing, precision and efficiency are paramount. One machine that plays a crucial role in achieving these standards, especially in the fabrication and maintenance of steel pipes, is the internal grinding machine. This specialized equipment is designed to grind the inner surfaces of pipes to achieve the desired finish and dimensions, which are vital for various industrial applications.

Steel pipes are used widely across numerous sectors, including construction, oil and gas, and manufacturing. Ensuring that these pipes are free of defects and have smooth interiors is essential for maintaining flow efficiency and preventing material degradation. Herein lies the importance of steel pipe internal grinding machine services.

Services Offered

The services provided by internal grinding machine specialists include the operation, maintenance, and repair of these machines, as well as the grinding itself. Skilled technicians use advanced grinding techniques to enhance the inner surfaces of the pipes. This process can effectively remove burrs, weld seams, and other imperfections, which are crucial for achieving the required tolerances.

Additionally, these services often include inspections and assessments of the steel pipes before and after grinding. By employing precision measurement tools, technicians ensure that the pipes meet industry specifications and customer requirements. This attention to detail helps to prevent future issues and prolongs the lifespan of the pipes.

Benefits of Professional Services

steel pipe internal grinding machine service

Engaging professionals in steel pipe internal grinding services brings numerous advantages. First and foremost, it guarantees a level of expertise and knowledge that is essential for achieving high-quality results. The technicians are adept at operating advanced grinding machines and understand the complexities of various steel grades and pipe diameters.

Moreover, outsourcing these services allows manufacturers to focus on their core competencies while ensuring that their steel pipes are processed correctly and efficiently. This not only improves productivity but also reduces operational costs. By eliminating the need for in-house grinding equipment and personnel, companies can save on expenses related to maintenance, training, and machine downtime.

Technology and Innovation

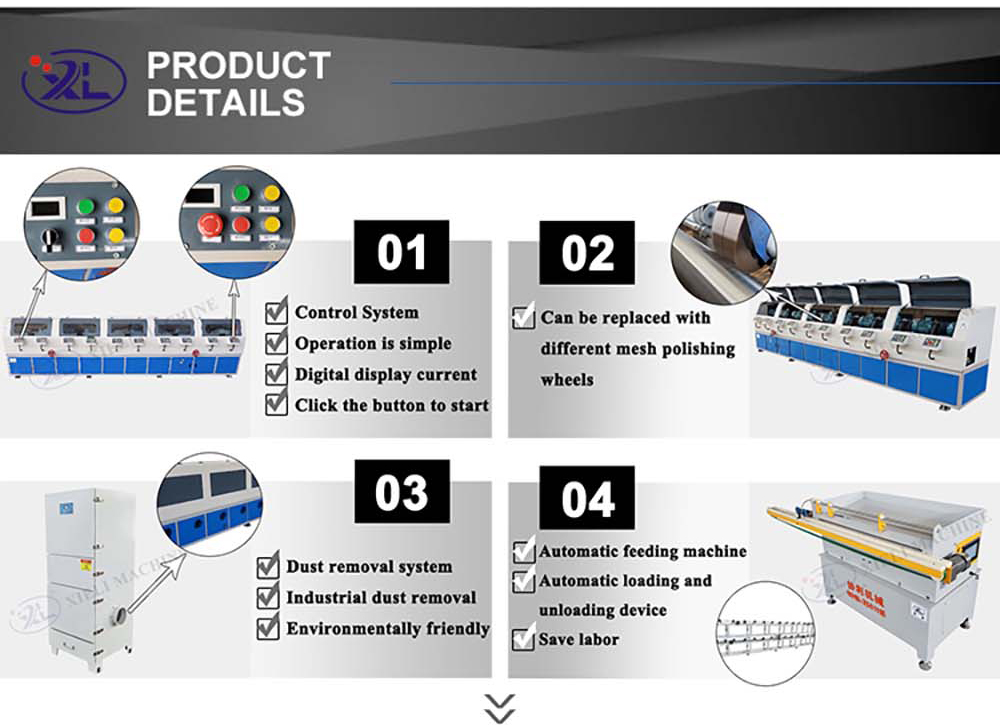

The development of modern internal grinding machines has incorporated various technological advancements, such as computer numerical control (CNC) systems. These innovations enhance precision and repeatability, which are essential in today’s competitive market. A reputable service provider will stay abreast of these technological changes to offer the best solutions to their clients.

Conclusion

In conclusion, steel pipe internal grinding machine services are integral to the manufacturing and maintenance of steel pipes. With their ability to enhance the quality and efficiency of pipes, these services contribute significantly to a myriad of industries. By entrusting the grinding process to skilled professionals, businesses can ensure that their operations remain streamlined and compliant with industry standards. In a world where precision is key, investing in reliable internal grinding services is a step toward achieving excellence in production and maintenance.