The Importance of Stainless Tube Polishing Machine Factories in Modern Industry

In the realm of manufacturing and fabrication, the need for high-quality finishing processes is paramount. One of the essential components in achieving superior quality is the polishing of stainless steel tubes. This is where stainless tube polishing machine factories come into play, offering innovative solutions that enhance the aesthetic and functional properties of stainless steel products.

The Role of Stainless Tube Polishing Machines

Stainless tube polishing machines are specifically designed for the surface finishing of stainless steel tubes. They serve a critical role in various industries, including automotive, aerospace, construction, and food processing. These machines utilize advanced polishing techniques to remove surface imperfections, such as scratches and oxidation, resulting in a smooth, shiny finish that not only appeals aesthetically but also enhances corrosion resistance.

Polishing stainless steel tubes is crucial for applications that require high hygiene standards, such as food and pharmaceutical industries. Thoroughly polished surfaces reduce the likelihood of bacterial contamination, making these machines indispensable for manufacturers aiming to meet strict health and safety regulations.

Key Features of Stainless Tube Polishing Machines

1. Efficiency Modern stainless tube polishing machines are engineered for high efficiency. They are capable of processing multiple tubes in a single cycle, significantly reducing production time while maintaining consistent quality across batches.

2. Customization Different applications require different polishing standards. Manufacturers often provide customizable machines that can be tailored to specific needs, whether it's for varying tube diameters, lengths, or desired finishes.

3. Automation With advancements in technology, many stainless tube polishing machines are now equipped with automation features. This not only streamlines the polishing process but also reduces the risk of human error, ensuring higher precision and reproducibility in surface finishes.

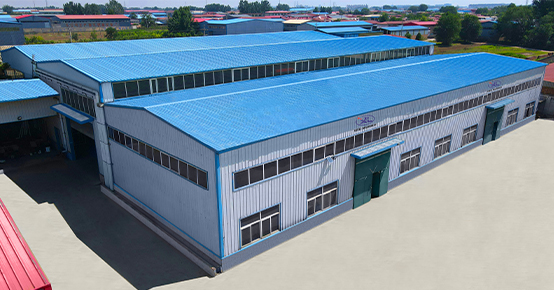

stainless tube polishing machine factory

4. Eco-Friendliness An increasing emphasis on sustainability is driving many factories to develop eco-friendly polishing machines. These machines utilize specialized polishing compounds and techniques that minimize waste and environmental impact.

The Manufacturing Process

The production process of a stainless tube polishing machine begins with the design and engineering phase, where manufacturers create prototypes based on industry standards and customer inputs. Once the design is finalized, high-grade materials are sourced to ensure the durability and longevity of the machines.

Following fabrication, rigorous testing is conducted to ensure that each machine meets safety standards and operational efficiency benchmarks. After successful testing, the machines are then assembled, and quality control checks are conducted before they reach the market.

Market Trends and Future Outlook

As industries continue to evolve, the demand for polished stainless steel tubes is expected to grow. This is particularly evident in sectors that require aesthetic appeal and sanitary conditions, such as decorative architecture and food-related components. Consequently, stainless tube polishing machine factories are likely to see continuous innovation, focusing on enhancing efficiency, reducing costs, and integrating advanced technologies such as artificial intelligence and IoT.

Moreover, the global shift towards sustainability means manufacturers will increasingly prioritize eco-friendly practices in their operations. This trend will likely spark new innovations in polishing techniques that conserve resources and minimize environmental impact.

Conclusion

In conclusion, the role of stainless tube polishing machine factories is vital in today’s manufacturing landscape. Their contribution to enhancing the quality, performance, and compliance of stainless steel products cannot be overstated. As technological advancements continue to shape the industry, these factories will remain at the forefront, providing essential tools that help various sectors achieve their goals while promoting sustainability and efficiency. Whether in ensuring optimum hygiene standards or enhancing product aesthetics, the importance of these machines in modern manufacturing is unmistakable.